Catalytic oxidation treatment process for carbon fiber oxidation unit tail gas

A catalytic oxidation and treatment process technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems that the exhaust gas of the oxidation unit cannot meet the environmental protection requirements, the incineration exhaust gas is large, and the operation cost is high, so as to achieve stable operation , low operating cost, and thorough exhaust gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The tail gas of the carbon fiber oxidation unit of the present invention comes from a polyacrylonitrile synthetic carbon fiber production device of a certain company, and the working conditions are shown in Table 1.

[0028] Table 1 Composition of exhaust gas from the oxidation unit of polyacrylonitrile synthetic carbon fiber in a company

[0029] serial number

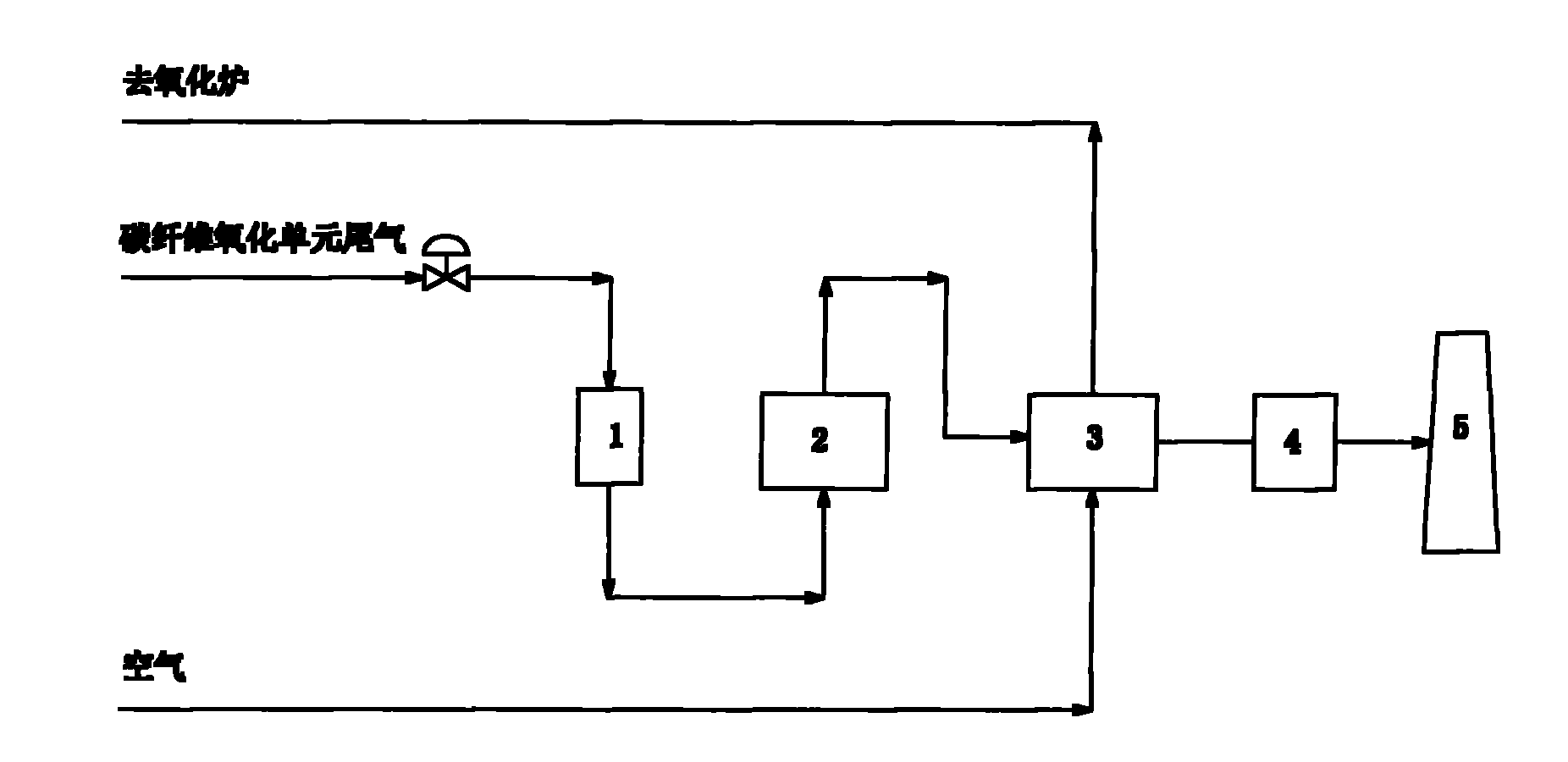

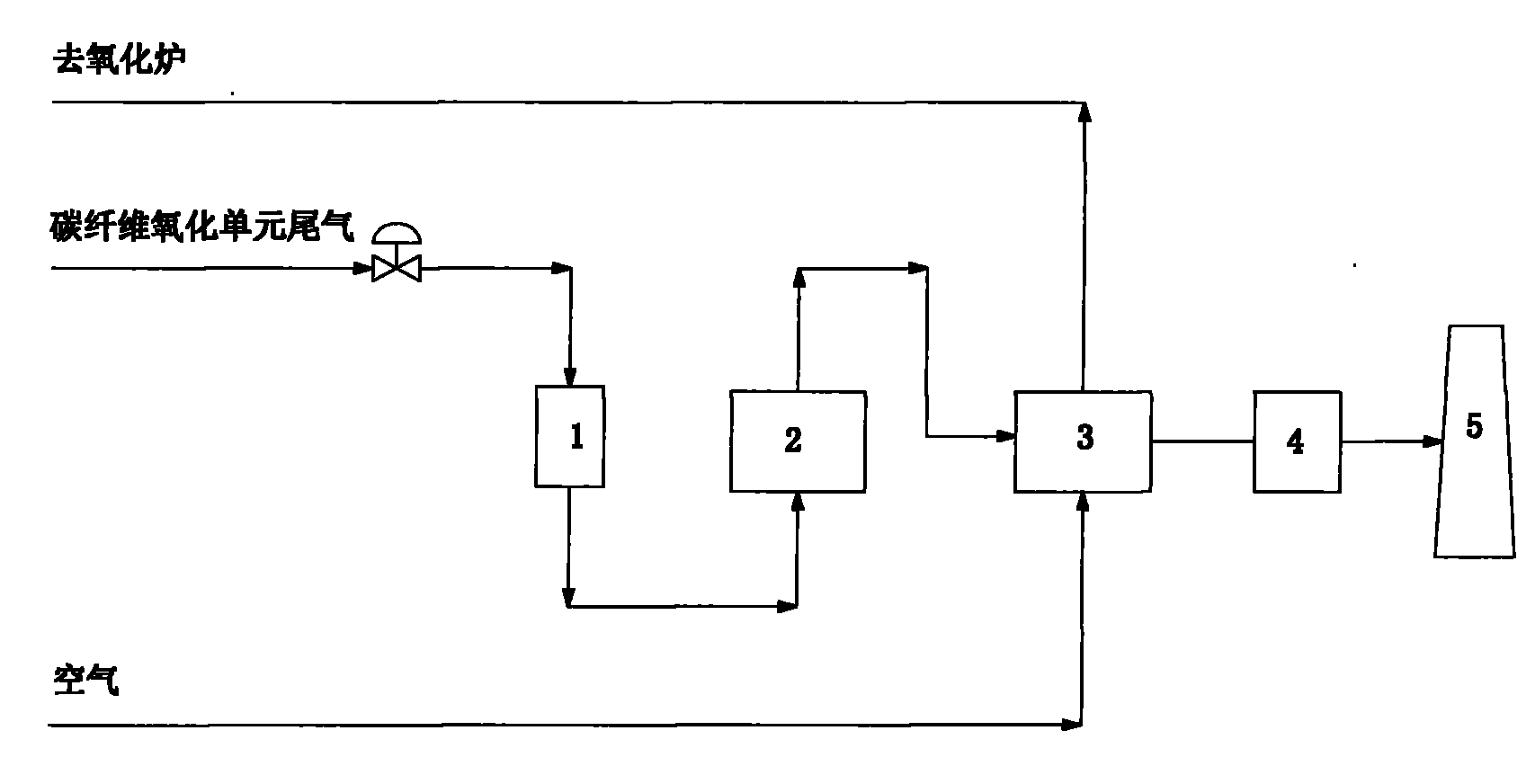

[0030] The tail gas from the polyacrylonitrile synthetic carbon fiber oxidation unit goes through the impurity remover 1 to remove impurities such as silicone oil and dust, and then enters the catalytic oxidation reactor 2. The impurity remover 1 and the catalytic oxidation reactor 2 respectively adopt the mixture of ferric oxide and manganese oxide as the catalyst, and the above-mentioned tail gas is carried out catalytic oxidation reaction in the catalytic oxidation reactor 2, and the pressure is about -3kPa (G), and the inlet temperature At about 220°C and an outlet temperature of about 300°C, harm...

Embodiment 2

[0037] The impurity remover 1 adopts ferrous oxide catalyst, the catalytic oxidation reactor 2 adopts manganese dioxide catalyst, the internal pressure of the catalytic oxidation reactor 2 is about -15kPa(G), the inlet temperature is about 110°C, and the outlet temperature is about 220°C, All the other are with embodiment 1.

[0038] The treated exhaust gas was sampled and sent to the laboratory for testing. The test results for the content of non-methane total hydrocarbons, ammonia, hydrogen cyanide and nitrogen oxides in the purified tail gas are shown in Table 3.

[0039] Table 3 Monitoring data and control indicators of a provincial environmental monitoring center station

[0040] Pollutant name

Embodiment 3

[0042] The impurity remover 1 and the catalytic oxidation reactor 2 respectively use ferric oxide catalyst, the internal pressure of the catalytic oxidation reactor 2 is about -5kPa(G), the inlet temperature is about 160°C, the outlet temperature is about 280°C, and the rest are implemented in the same way example 1. The treated exhaust gas was sampled and sent to the laboratory for testing. The results of the content testing of non-methane total hydrocarbons, ammonia, hydrogen cyanide and nitrogen oxides in the purified tail gas are shown in Table 4.

[0043] Table 4 Monitoring data and control indicators of a provincial environmental monitoring center station

[0044] Pollutant name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com