Up feeding and down feeding double-grading type high-efficient powder concentrator

A double-classification, powder separator technology, applied in solid separation, separation of solids from solids by airflow, chemical instruments and methods, etc., to avoid uneven cutting particle size, reduce system energy consumption, and uniform airflow distribution stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

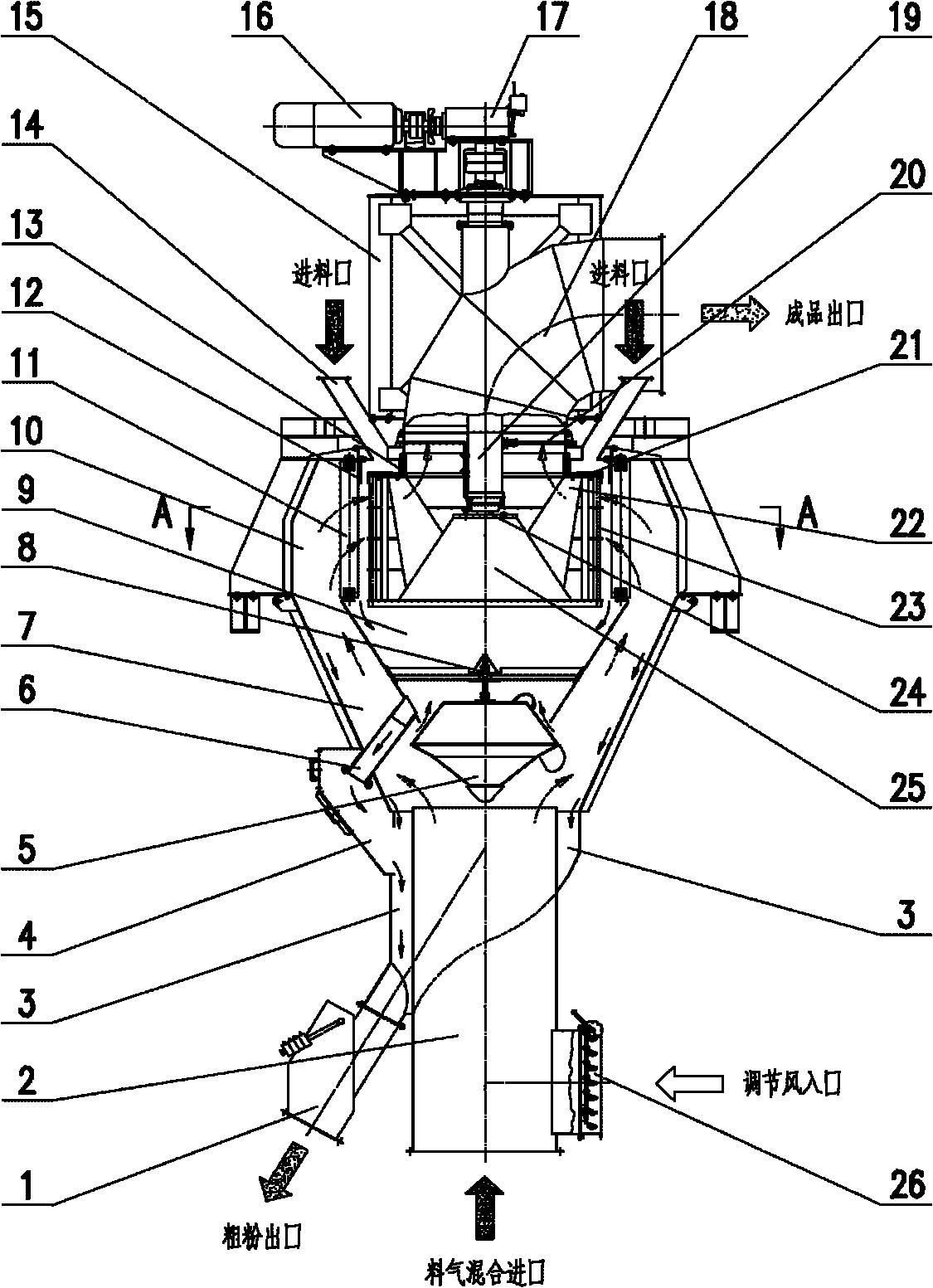

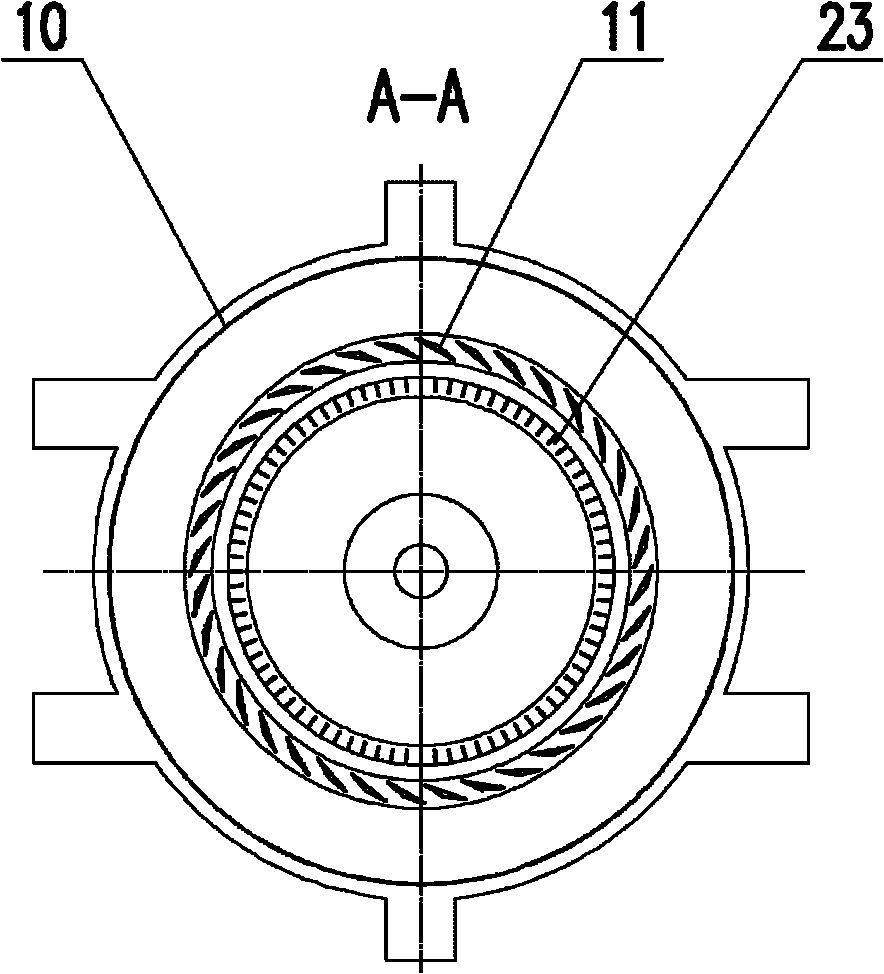

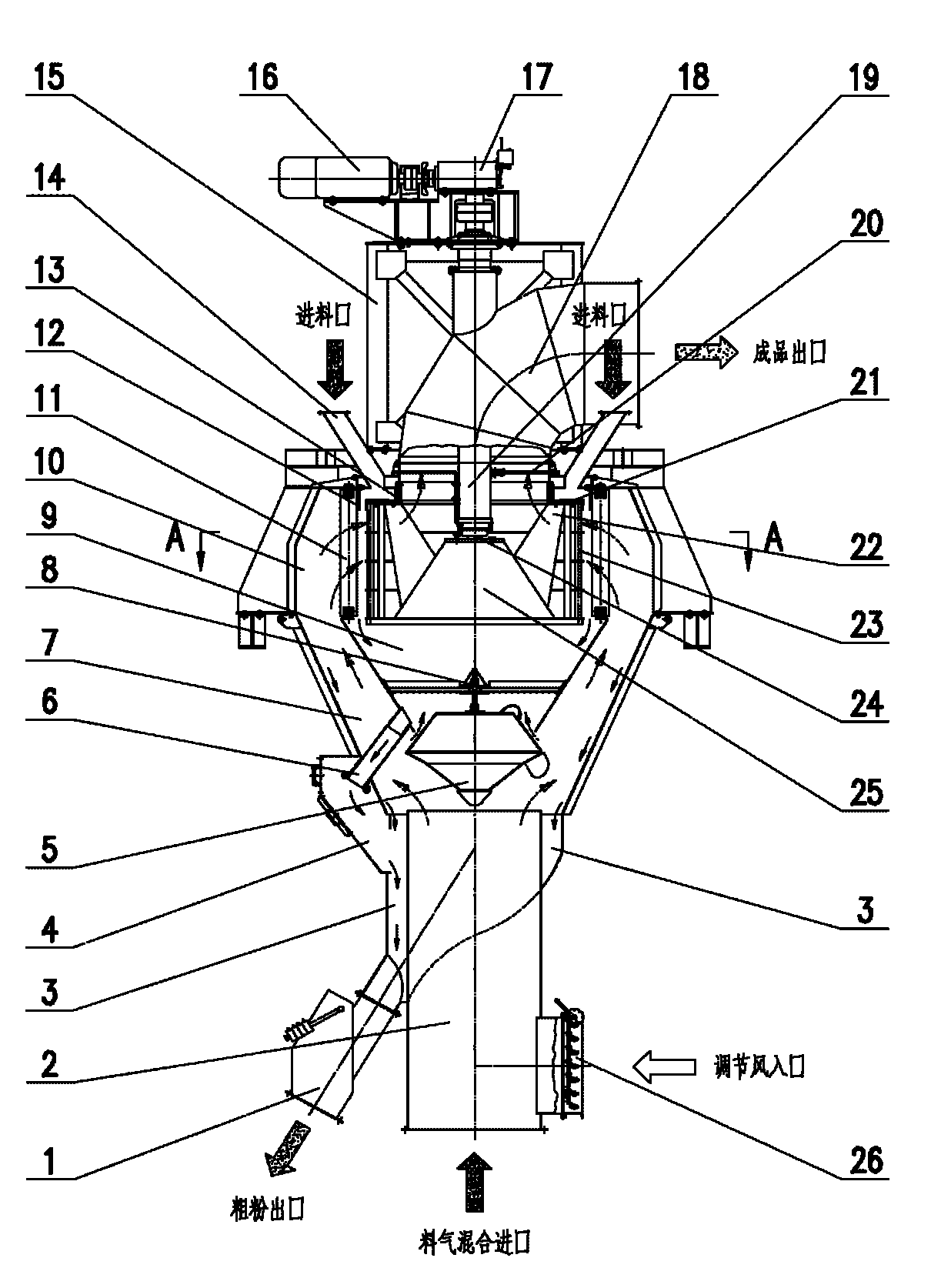

[0024] In order to further understand the invention content, characteristics and effects of the present utility model, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer tofigure 1 and figure 2 , the present invention mainly consists of an upper casing 10, a middle casing 7, a lower casing 3, a transmission bracket 15, a blanking nozzle 6, a grading rotor 25, a main shaft sleeve 19, a main shaft 24, a spreading disc 21, a grading blade 23 and an installation The reducer 16 and the motor 17 on the transmission bracket 15 are composed of the upper shell 10, which is formed by a truncated hollow cone and a hollow cylinder butt welded up and down, and a large curved pipe at the air outlet is connected to the center of the upper end. 18. The inlet and outlet passages of the large curved pipe 18 at the air outlet can be arranged vertically or upwardly, with an included angle ranging from 90° to 135°;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com