Fixture used for processing small moving blade in turbine and processing method thereof

A technology of moving blades and steam turbines, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of limited processing accuracy, low processing efficiency, and poor application of superior performance of machine tools, etc., and achieve processing costs The effect of reducing and improving processing efficiency and high one-time inspection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

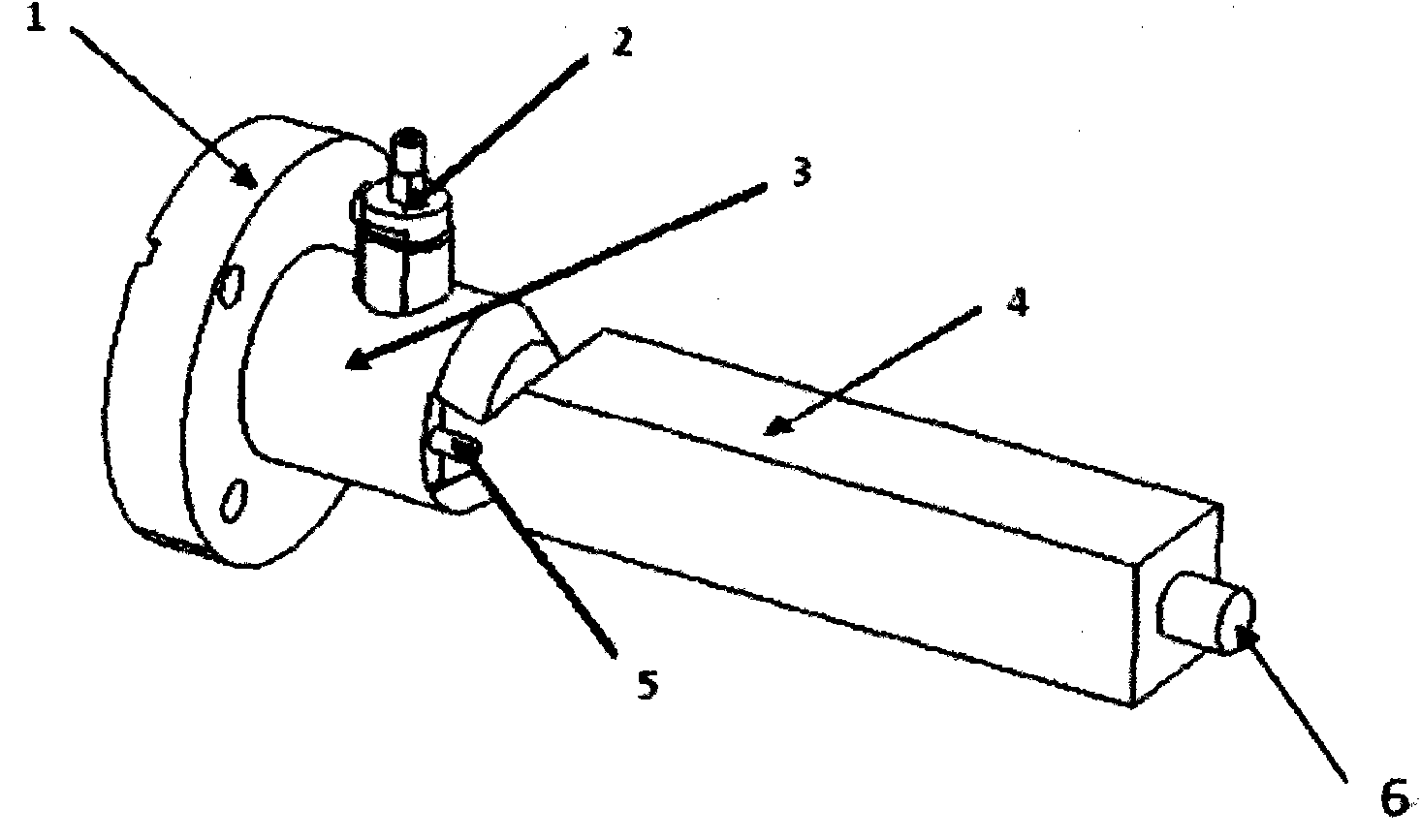

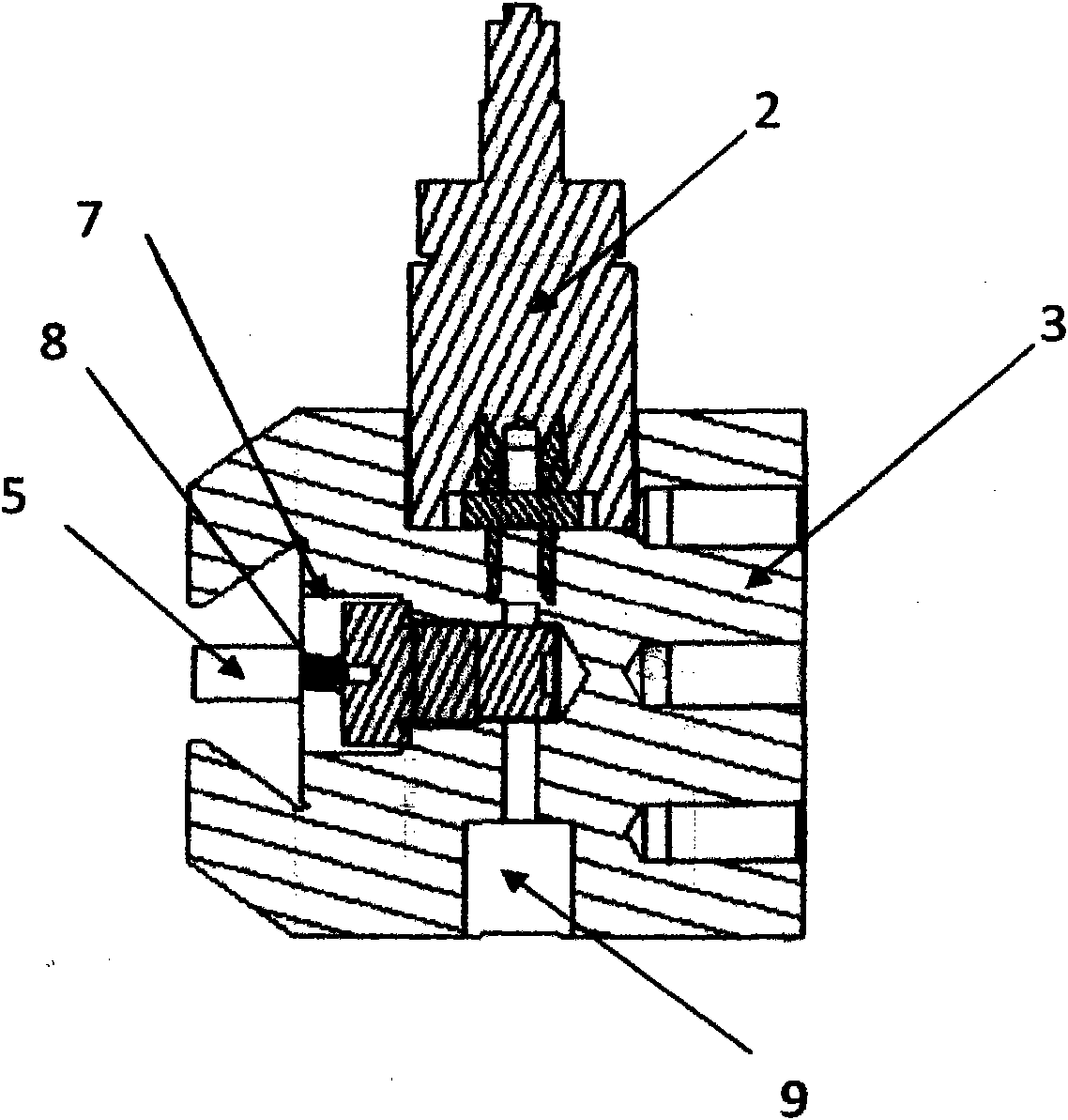

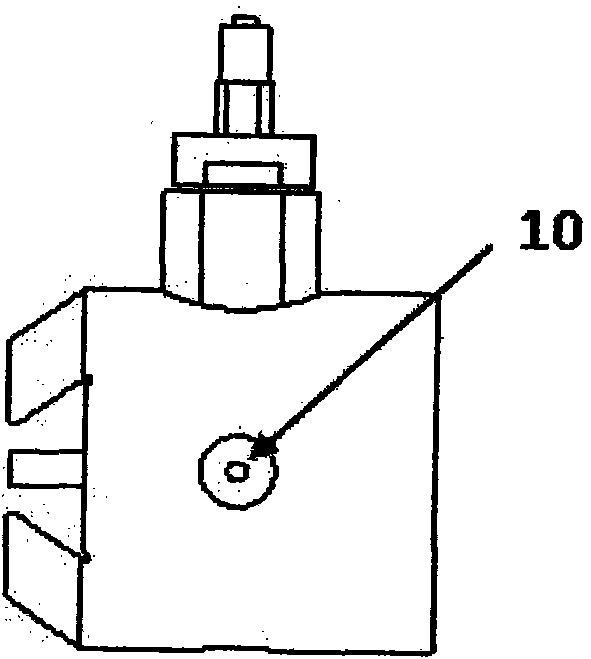

[0023] see figure 1 , figure 2 , image 3 Summary of the invention: the present invention is a kind of processing fixture of small and medium movable blade, and this fixture can realize the one-time clamping of workpiece on the numerical control machine tool of more than five axes. The clamp includes a transmission body 3 and its mounting plate 1 . The transmission body 3 is fixed on the mounting plate 1, and the end surface of the transmission body 3 has a dovetail groove for installing blade blanks. The blade blank 4 installed on the fixture has a technical tenon, which is dovetail-shaped and fits with the dovetail groove of the fixture. The transmission body 3 is provided with a linear hydraulic cylinder 7, and its piston rod 8 corresponds to the above-mentioned technical tenon. The transmission body 3 is also provided with an accumulator 2, a pressure charging port 9 and an overflow safety valve 10, and the linear hydraulic cylinder 7, the accumulator 2, the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com