Energy storage stapling machine sending out stitching needle groove from front

An energy storage type, stapler technology, applied in the field of staplers, can solve the problems of small labor-saving ratio of the lever arm, not fast, inconvenient to take and take, etc., and achieves the effect of reasonable ratio of the lever arm and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

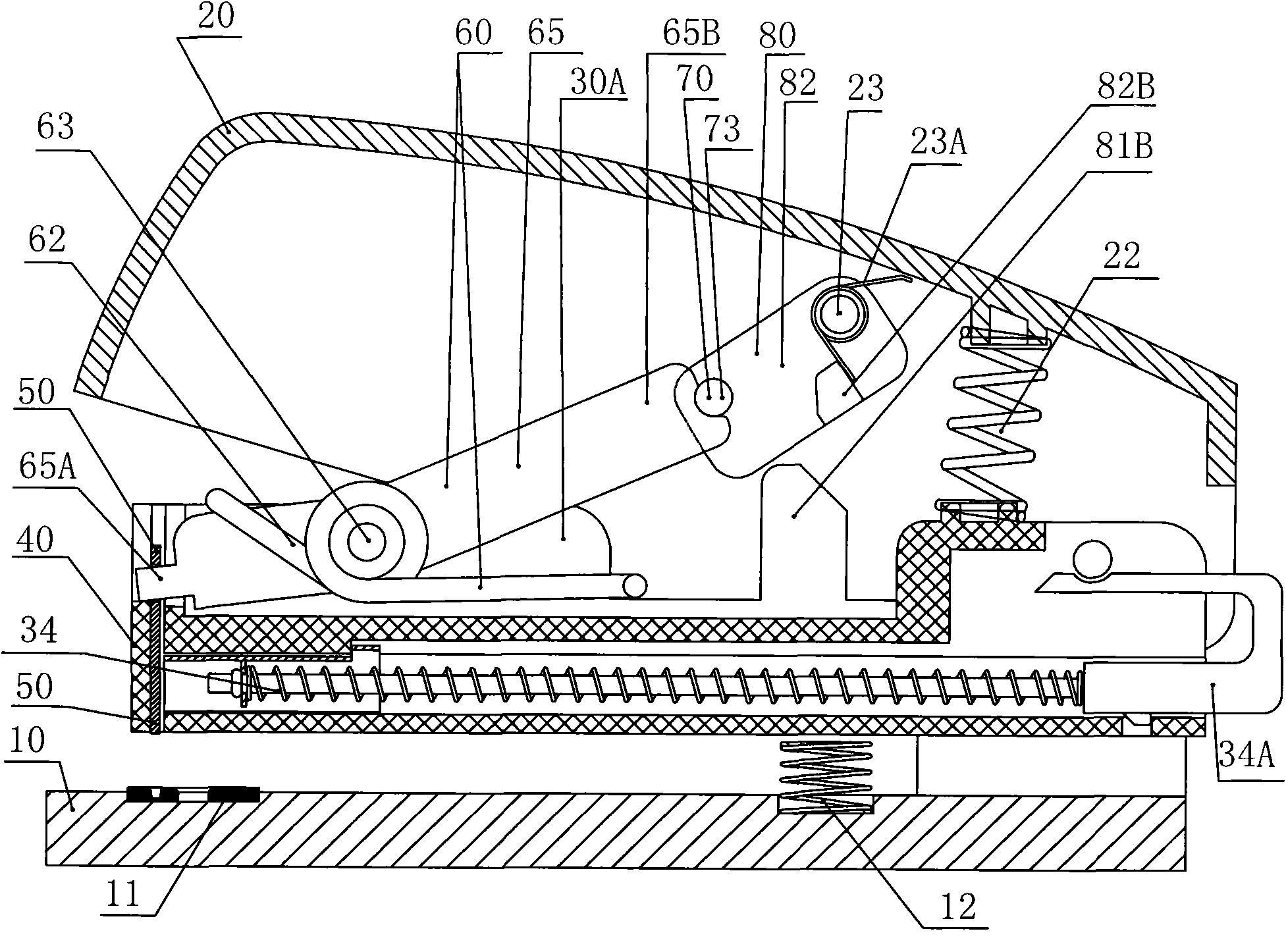

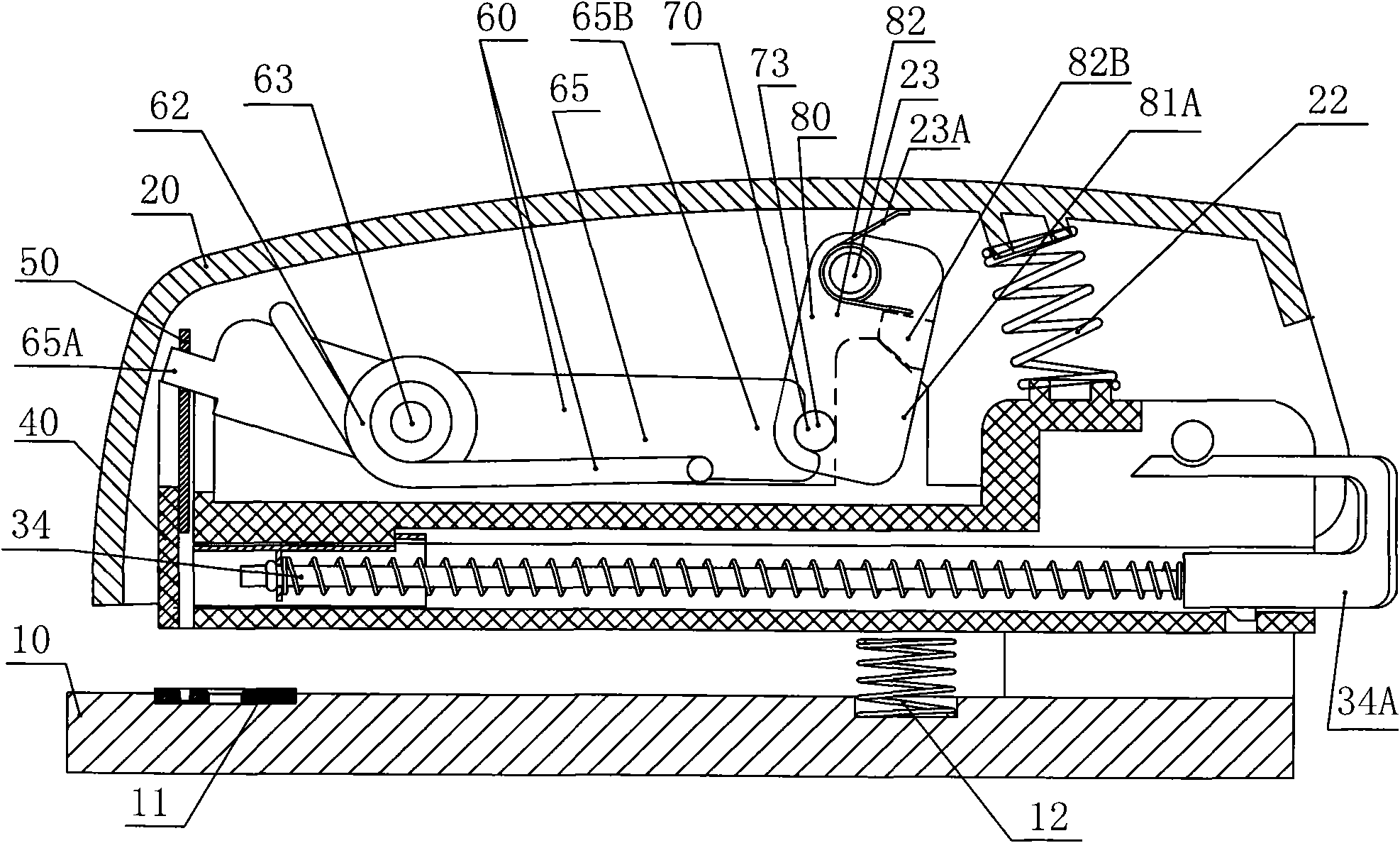

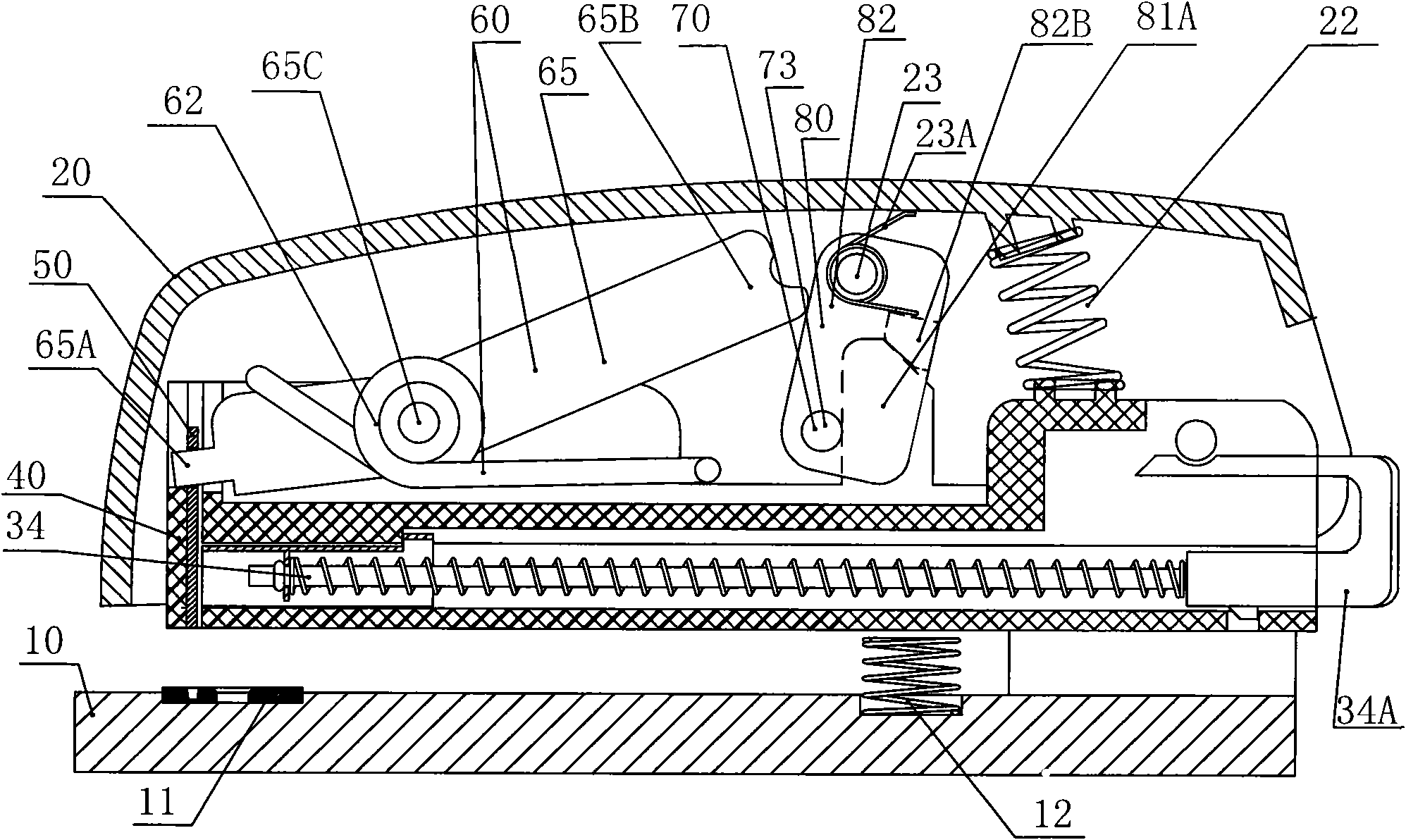

[0040] Such as Figure 4-13 , which are schematic diagrams showing the assembly and disassembly structures of Embodiment 1 of the present invention in various states; Figure 6~7 It is a three-dimensional schematic diagram of the dismantling structure of the staple sheet, the needle groove and the chute frame related to Embodiment 1 of the present invention.

[0041] Embodiment 1 of the present invention includes a base 10, an upper cover 20, a box 40 with a book needle groove 30 fitted therein, and a staple sheet 50 for pressing the book needles in the book needle groove 30, and the sliding fit in the box 40 is elastic. Needle pusher 34 and needle presser plate 40B. On the base 10, a needle plate 11 is provided at the position corresponding to the falling of the nail sheet 50, and a bottom spring 12 is also provided on the base 10; the box 40 is hinged on the base, and the upper cover 20 is in the box. 40, and hinged on the base; the staple piece 50 slides up and down to fi...

Embodiment 2

[0049] Such as Figure 14 , which is a schematic cross-sectional view of the structure of the book needle slot popping up and loading the needle with the leaf spring instead of the torsion spring energy storage in Embodiment 2 of the present invention; except that the parts such as the staple sheet and the box need to increase or decrease the corresponding structure to match the leaf spring, other structures All are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com