Corrosion-resistant repairing method for perforation of top plate of phosphoric acid reaction tank

A phosphoric acid reaction tank and top plate technology, applied in phosphoric acid, phosphorus oxyacids, etc., can solve the problems of difficult construction requirements and uneven construction work surfaces, and achieve the effects of consistent expansion coefficient, good use conditions, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] According to the following steps, the anti-corrosion repair method for the perforation of the top plate of the phosphoric acid reaction tank includes the following steps:

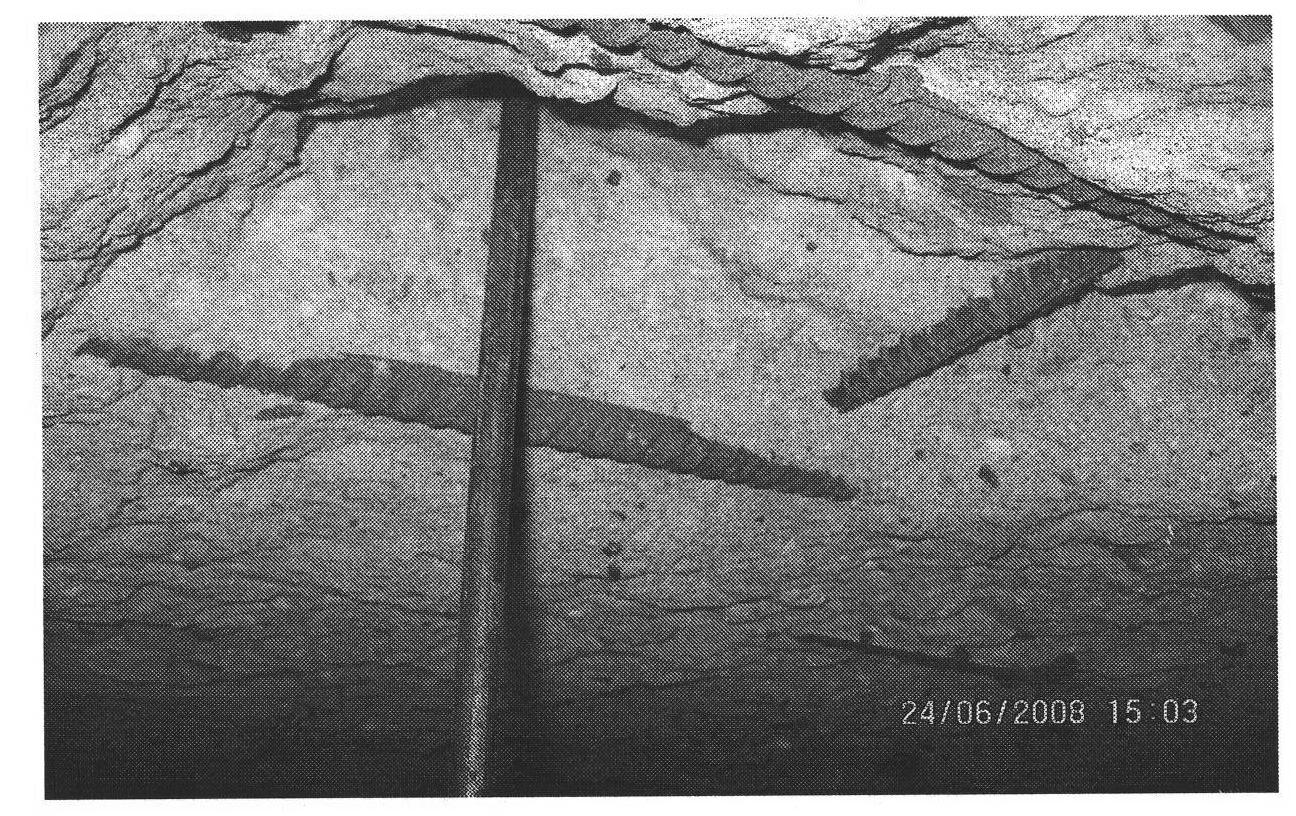

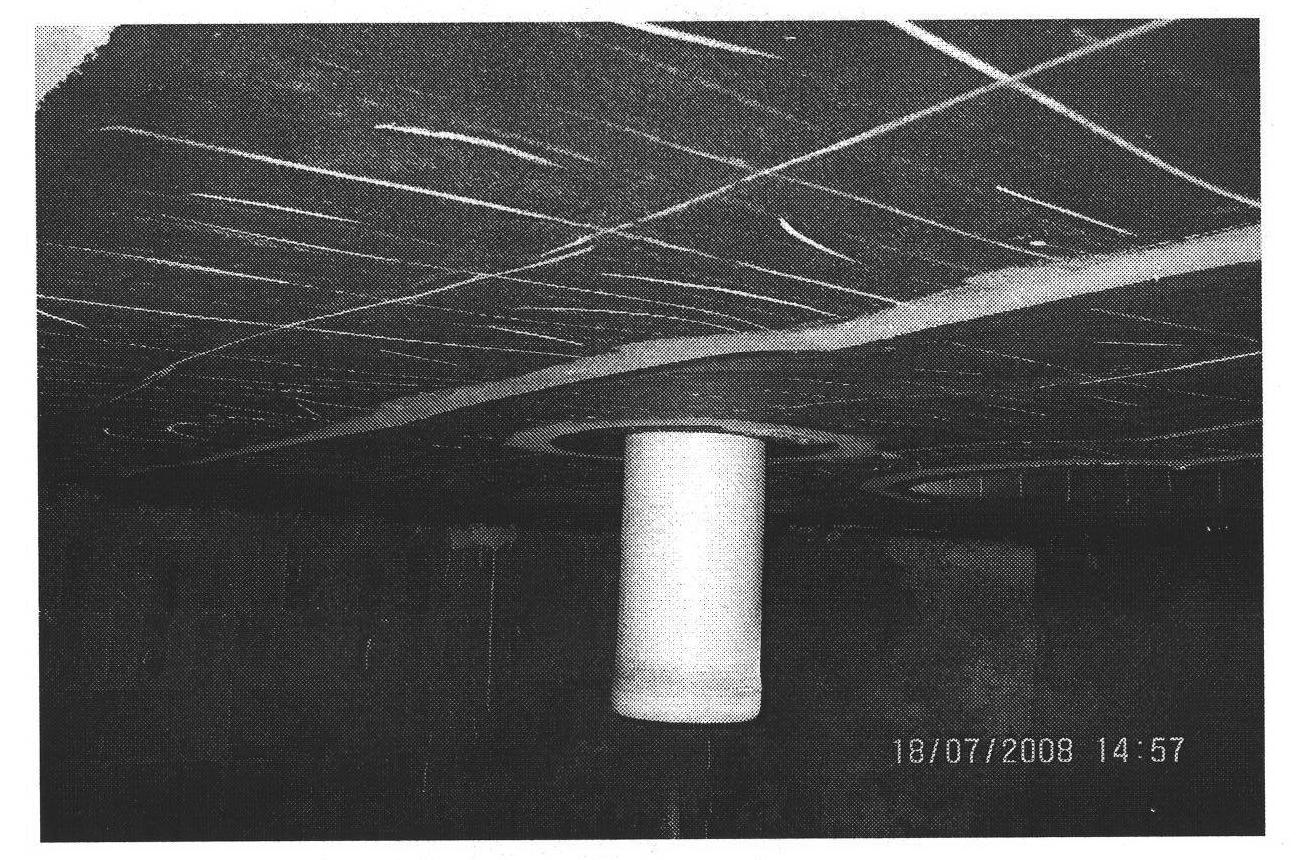

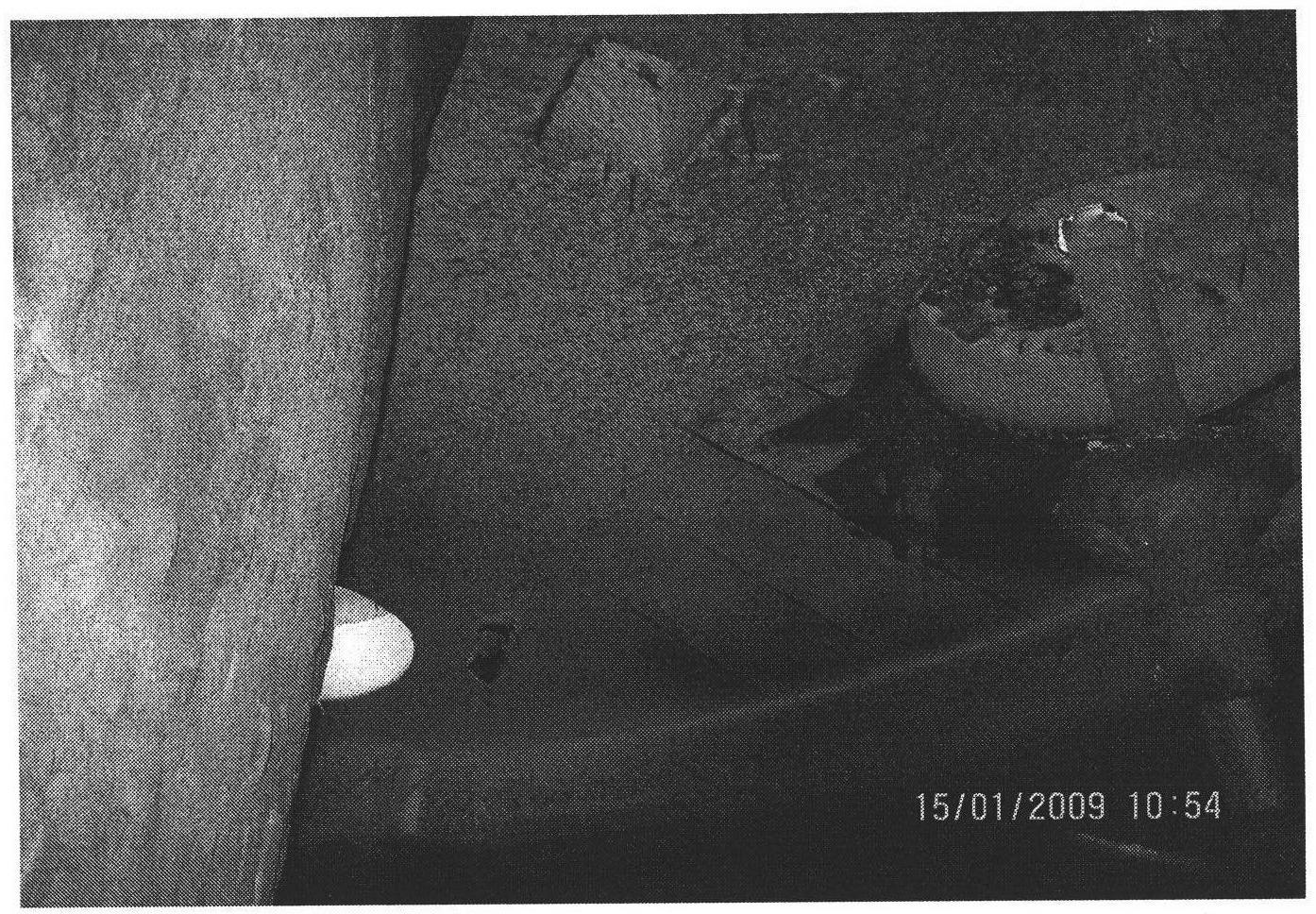

[0018] 1) Drill holes at the defects in the central area of the phosphoric acid reaction tank and the feeding port of the fifth area whose depth exceeds 50mm, install the steel plate after installing the anchor rod, and weld the anchor rod and the steel plate as a whole, pass the The top plate opening of the phosphoric acid reaction tank is filled with Kerakret ZE 230 (purchased from Kelangman Company) cement between the steel plate and the top plate of the phosphoric acid reaction tank, and the Kerakret ZE 230 cement is filled in the position where the corrosion hole of the concrete matrix is greater than 30mm , sandblasting the central area of the phosphoric acid reaction tank and the defects at the feeding port of the fifth area whose depth is less than 50mm to remove surface concrete floatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com