Method and device for two-for-one twisting vehicle web break alarm

A sound and light alarm and spindle technology, applied in textiles and papermaking, can solve the problems of increasing the force on the yarn and the yarn is easy to break, so as to improve production efficiency, ensure product quality, and facilitate timely processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

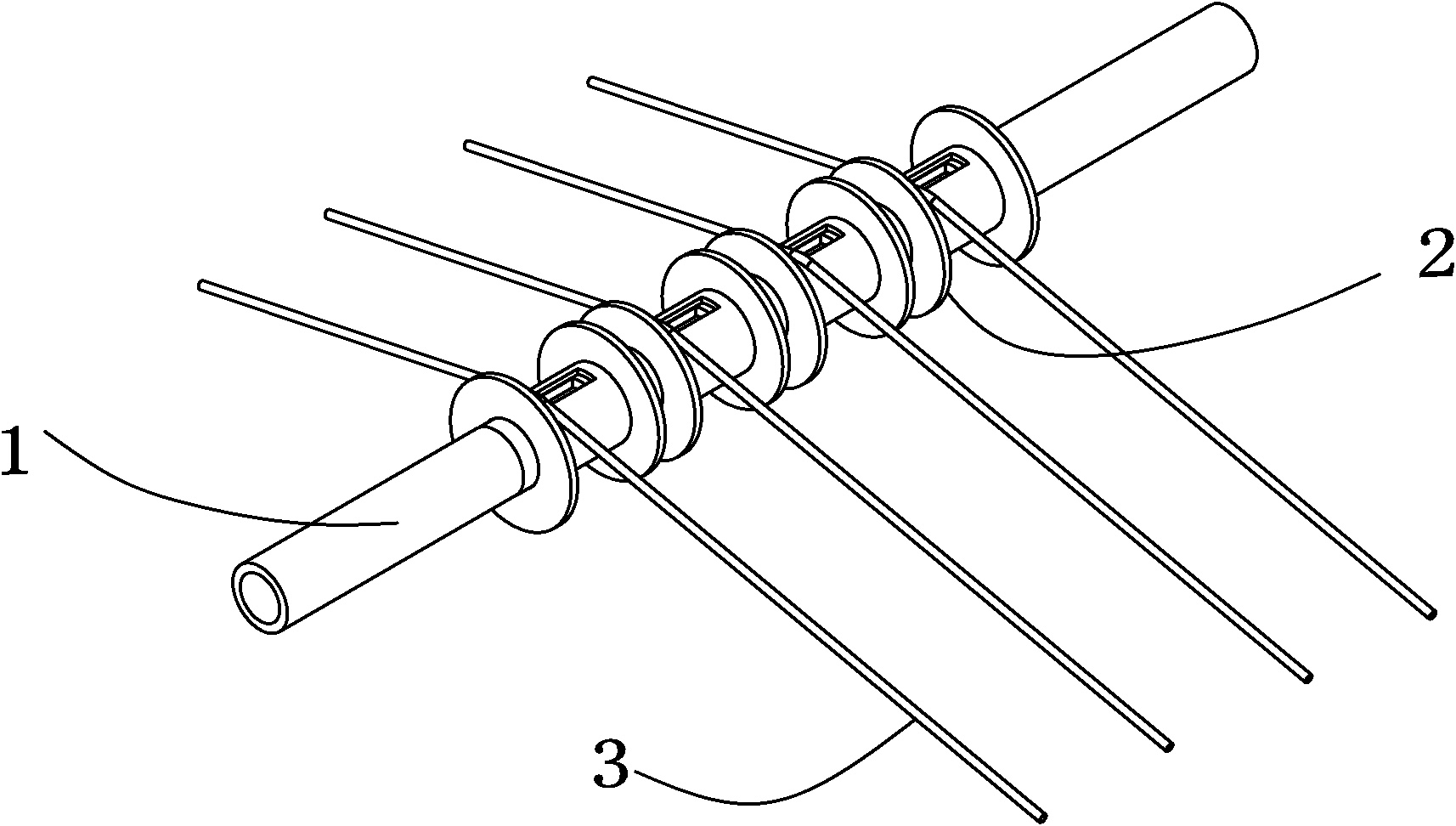

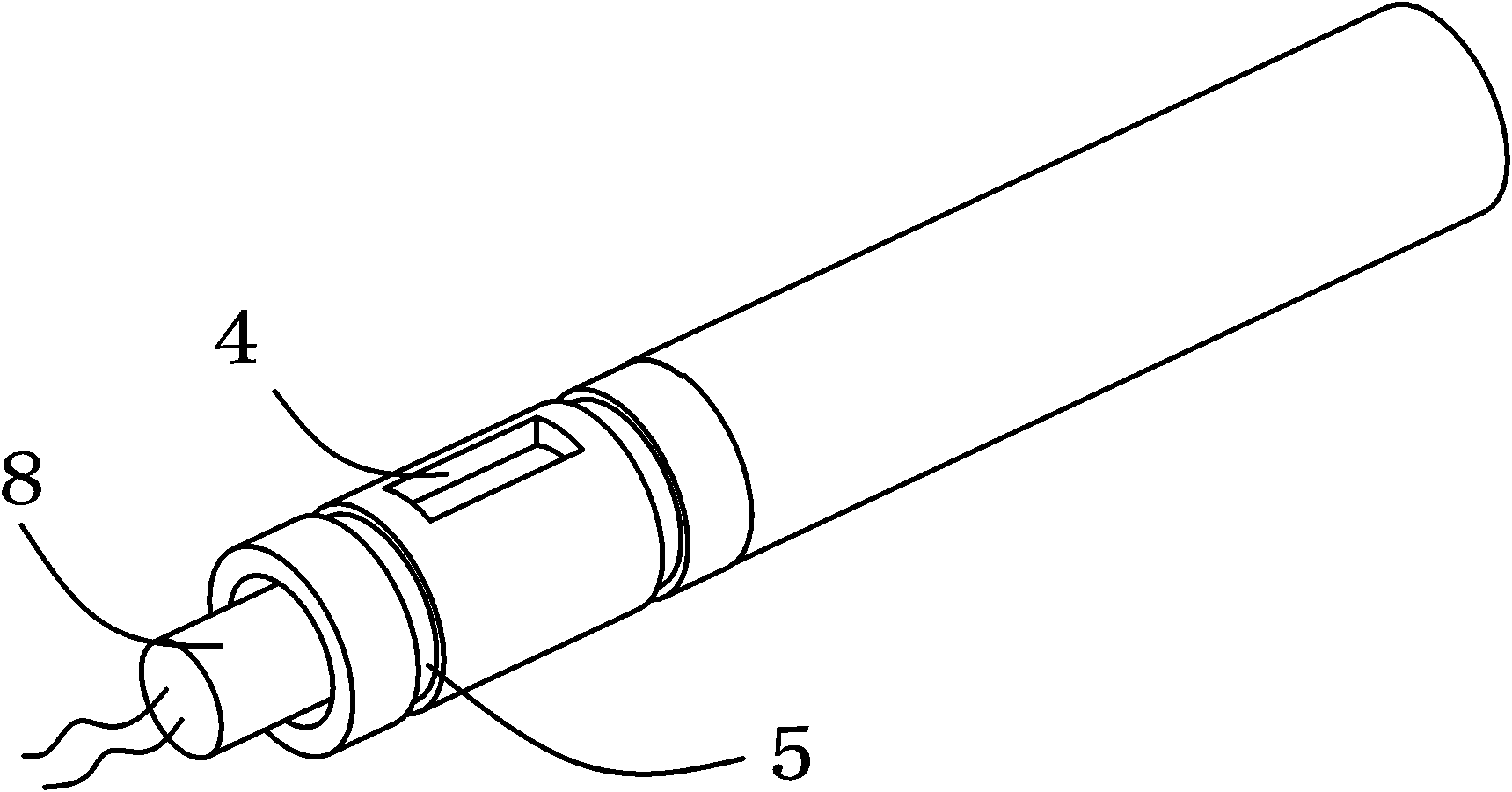

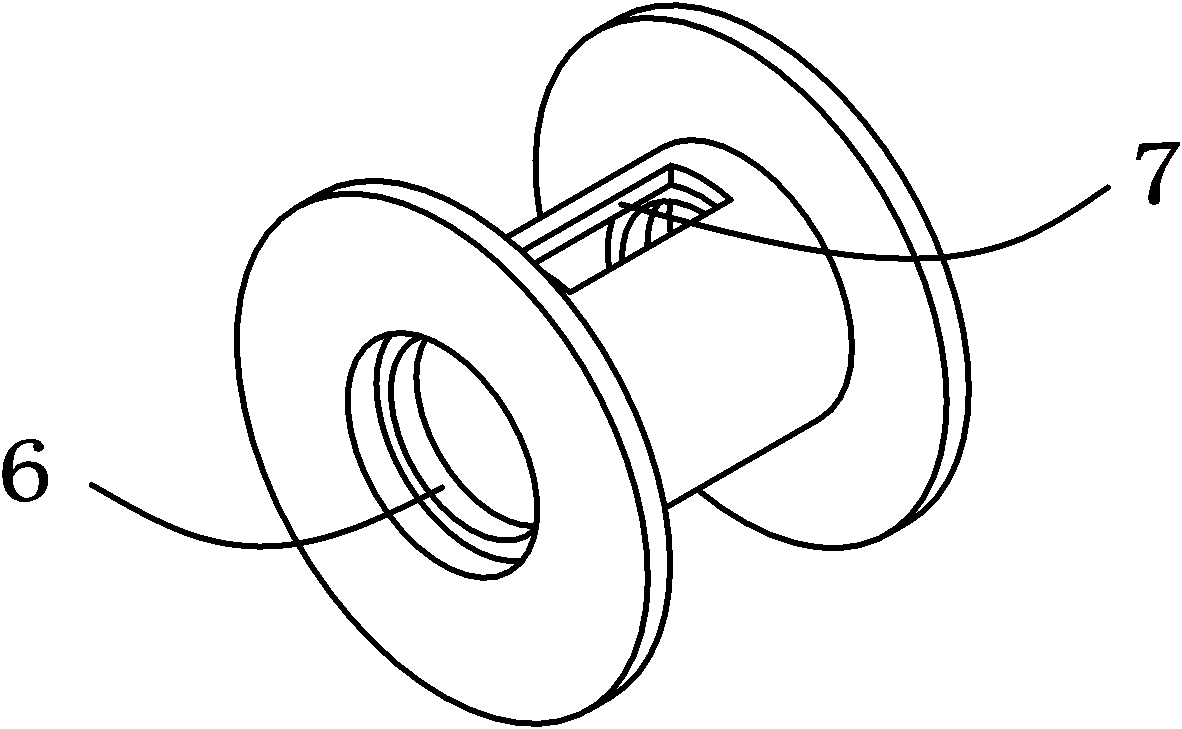

[0021] Example. A two-for-one twisting car breakage alarm method, characterized in that: the yarn is supported by a rotatable guide wheel on the main shaft, and rotates under the action of the yarn's own weight, tension and friction; the light-through hole on the main shaft and the guide wheel The guide wheel overlaps once every revolution, that is, the light passes through the main shaft once; when the yarn breaks, the guide wheel stops rotating, and the cycle process of "light-shielding" in the main shaft stops; by detecting the "light-shielding" in the main shaft Whether the shading cycle is stopped to determine whether the yarn is broken, and to activate the sound and light alarm in the event of a broken end. The cycle process of "light-passing-light-shielding" in the detection spindle is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com