Conveying mechanism and method of upper drilling platform and lower drilling platform of drilling pipe used for petroleum drilling

A conveying mechanism and drill pipe technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of low automation, low efficiency, and potential safety hazards, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

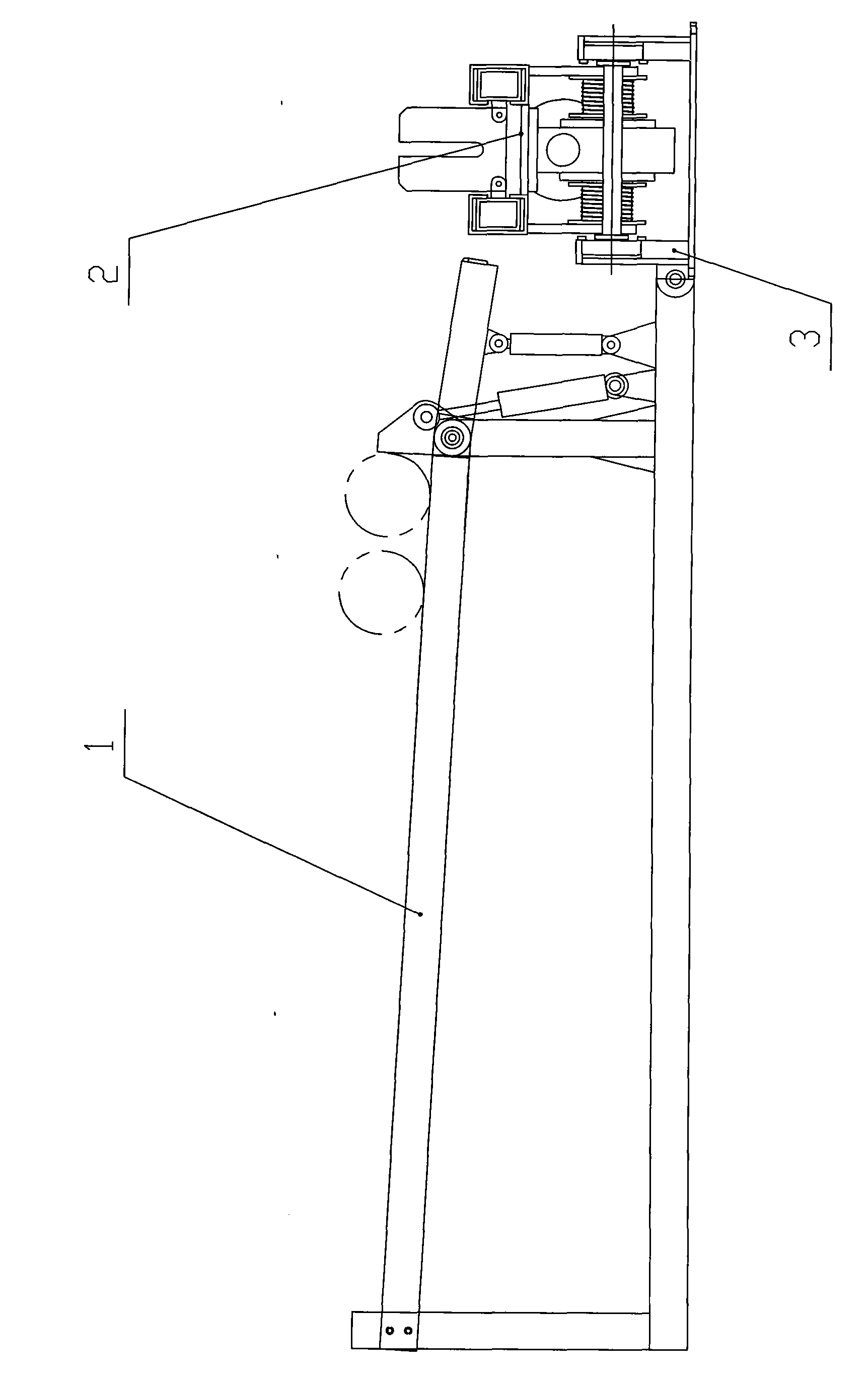

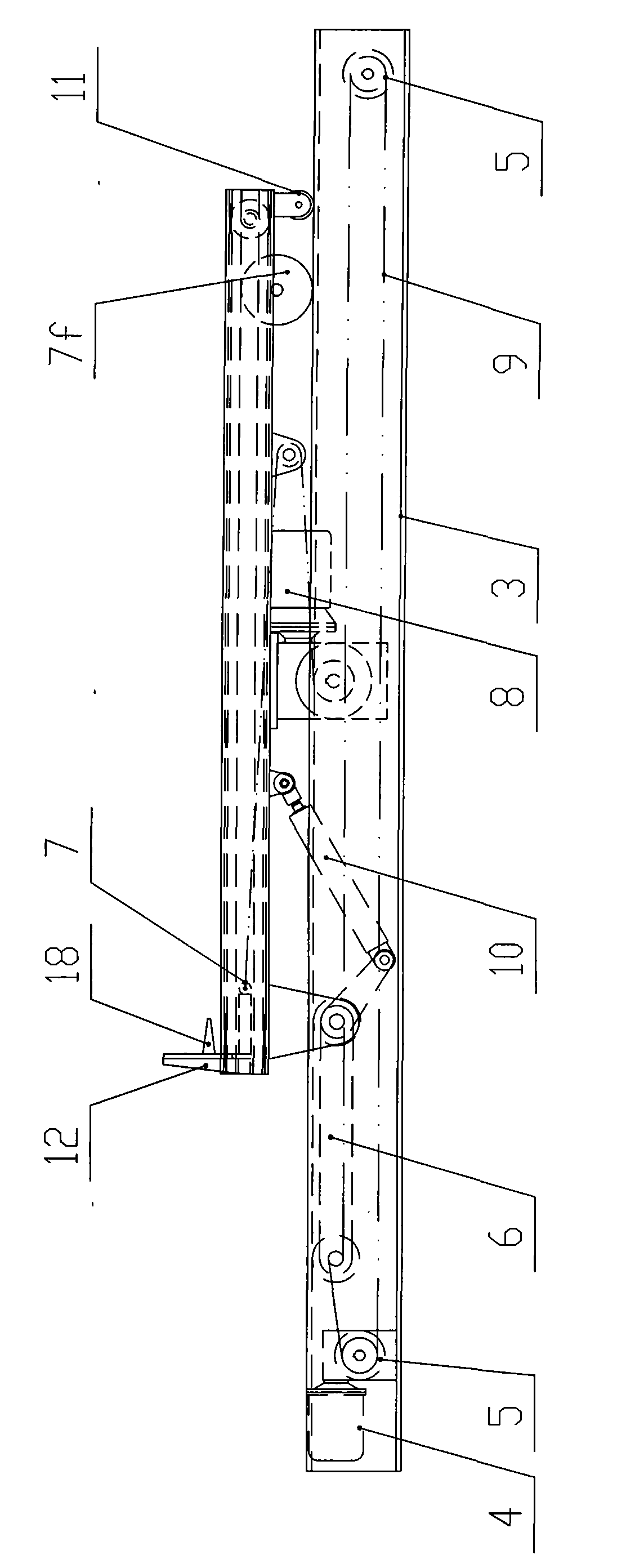

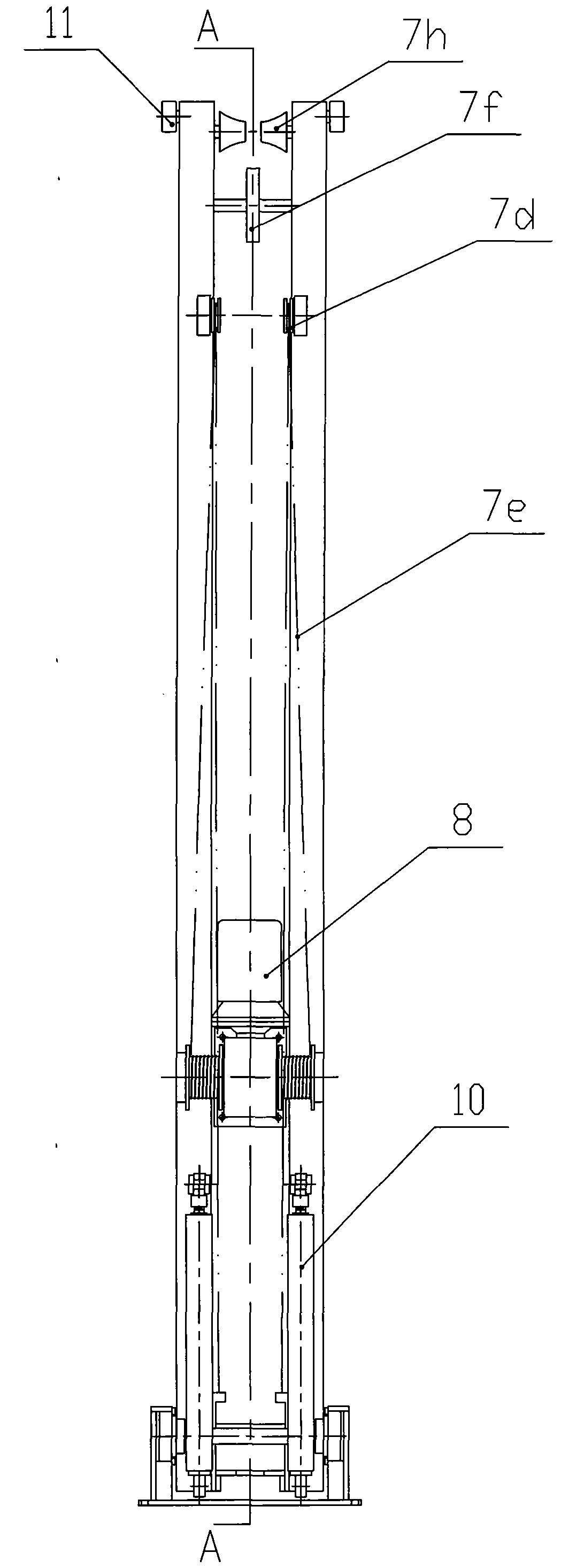

[0029] Such as figure 1 , 2 , 3, 4, 5, and 6: a conveying mechanism for drill pipes used for oil drilling up and down the drill floor, the mechanism includes a pipe rack 1, a conveying device 2 and a track 3, and the pipe outlet end of the pipe rack 1 Located above the track 3, the transmission device 2 includes a transmission motor 4, a transmission winch 5, a transmission trolley 6, a support arm 7, a lifting motor 8 and a lifting cylinder 10, and the pair of transmission winches 5 are arranged on At both ends of the track 3, a transmission cable 9 is wound between the two transmission winches 5, and the cable 9 is connected to the power shaft of the transmission trolley 6 at the same time; one end of the support arm 7 is hinged on the transmission On the trolley 6, the other end is provided with a sliding driven wheel 11. The support arm 7 is composed of a pair of parallel support rods 7a and telescopic rods 7b. The support rods 7a are hollow and the opposite inner sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com