Large vertical depth solid feeding system and large vertical depth solid feeding process for filling extracted coal

A technology of backfill mining and vertical depth, which is applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve problems such as endangering human safety, harm, and pollute the environment, and achieve the effects of wide practicability, convenient process and convenient implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

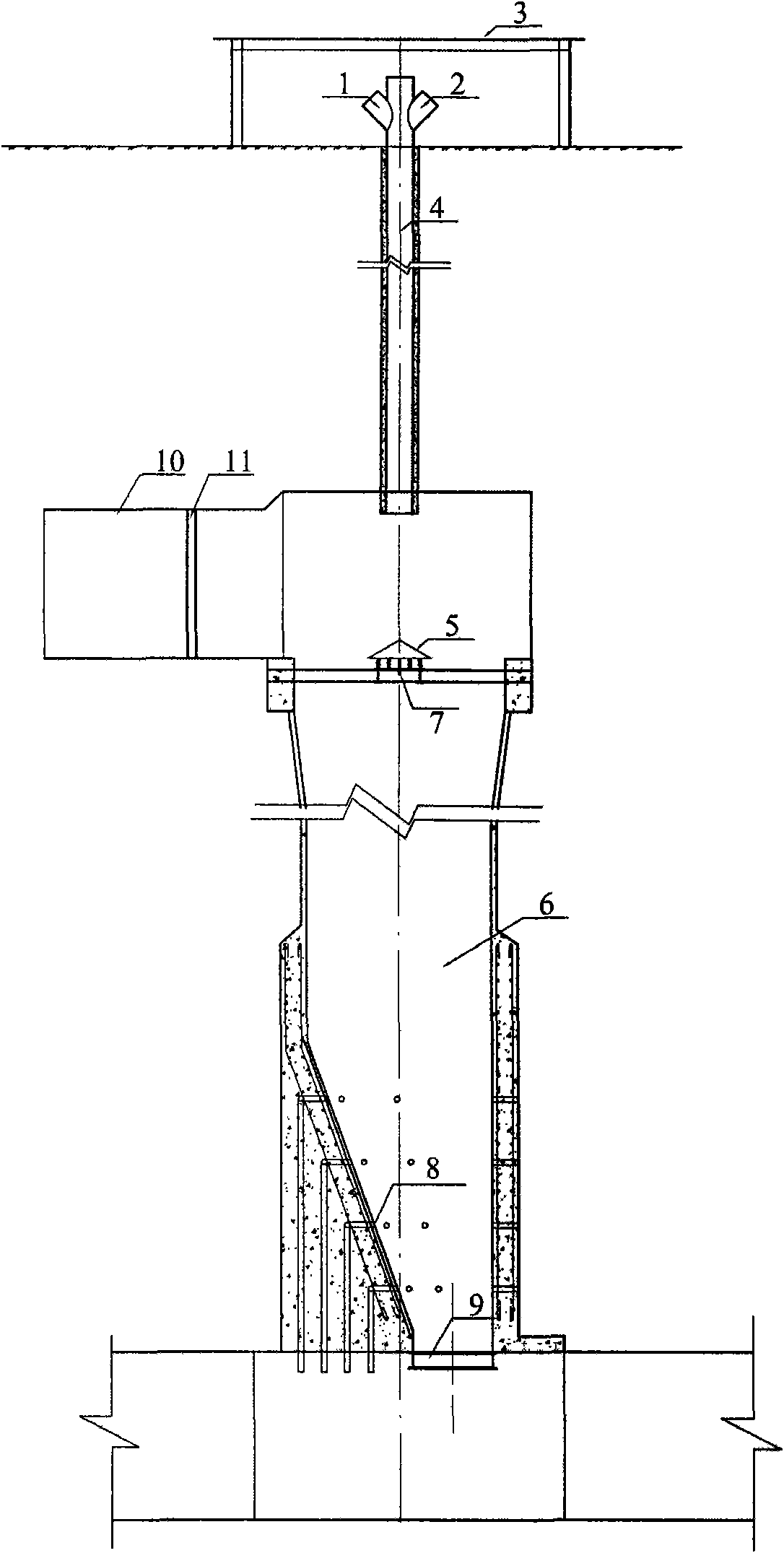

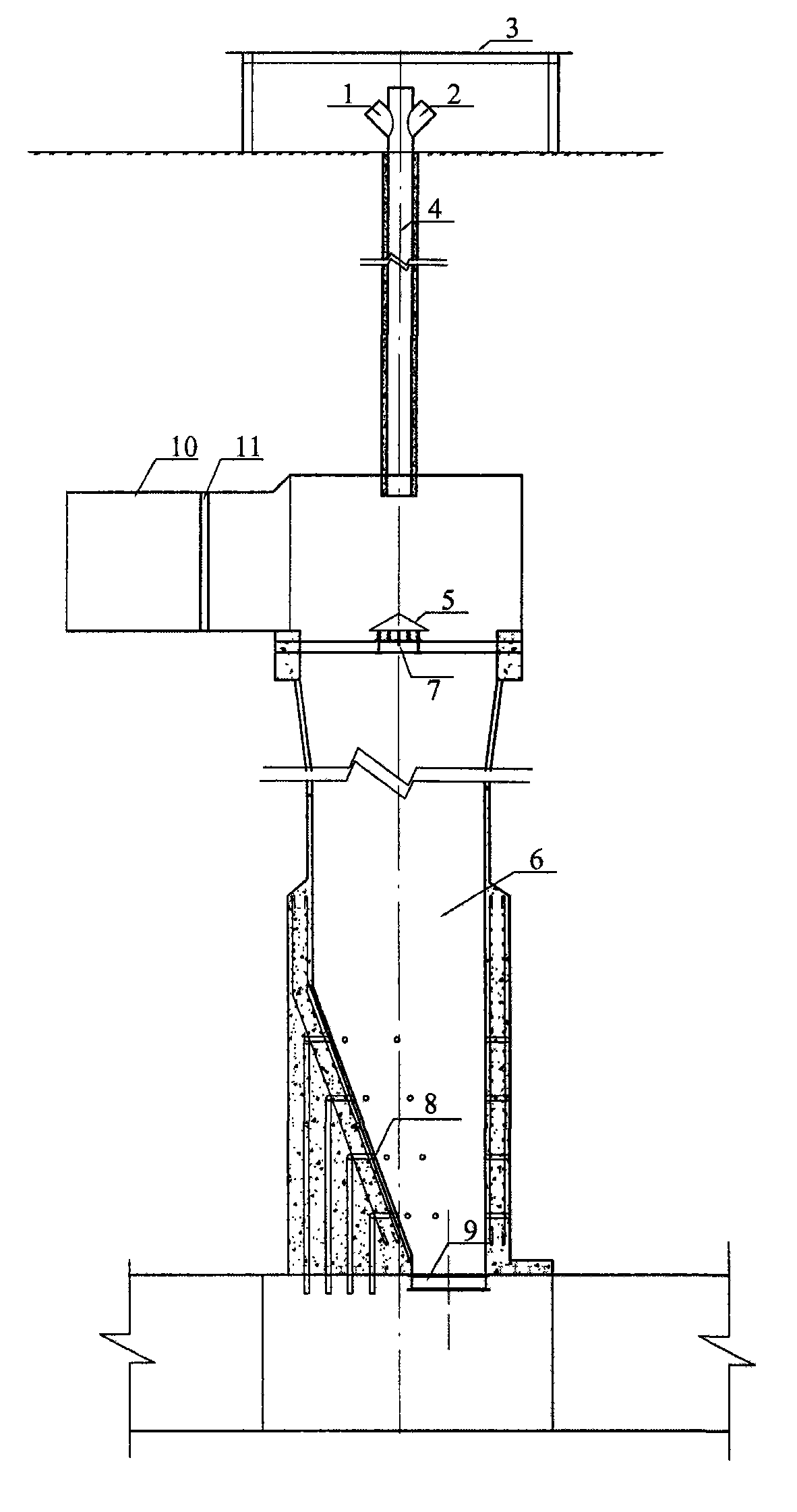

[0012] The large vertical depth solid feeding system for filling coal mining of the present invention is mainly composed of a ground console 3, a feeding pipeline, a well-type storage bin 6, a well wall cleaning device 8 and a bottom feeder 9, and the feeding pipeline is arranged on the ground Below the console 3, the feeding pipeline is composed of the main channel 4 and the branch pipelines 1 and 2 connected to the top of the main pipeline 4. The ground console 3 is controlled to drop different solid filling materials into the branch pipelines 1 and 2 according to the ratio. The steel pipe with a diameter of about 510×12mm used in the main passage 4 is used as the hole protection pipe, and the ceramic pipe is used as the wear-resistant inner pipe. The effective diameter is 486mm, the depth of the main passage 4 is about 300m, and the transportation capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com