Image pickup lens, image pickup apparatus, mobile terminal, and manufacturing method of image pickup lens

A camera lens and lens technology, applied in optics, instruments, electrical components, etc., can solve problems such as the difficulty of ambiguity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

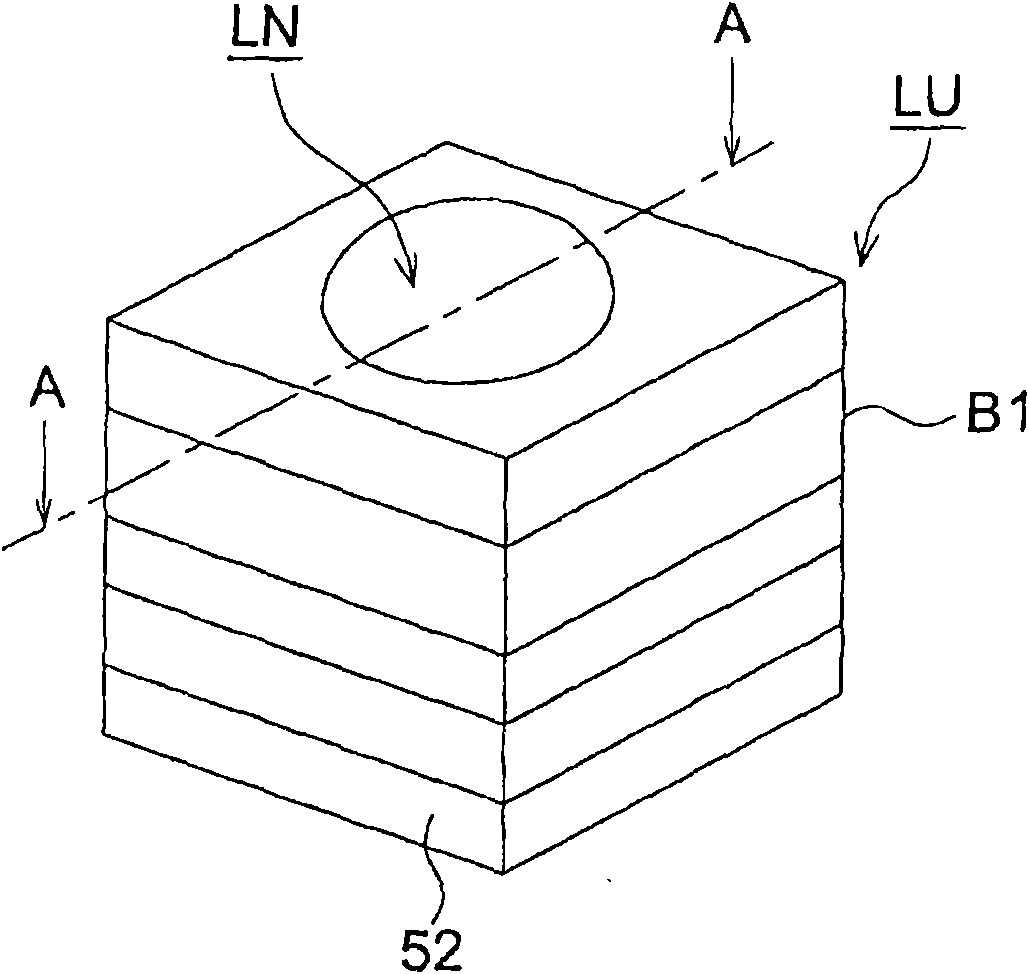

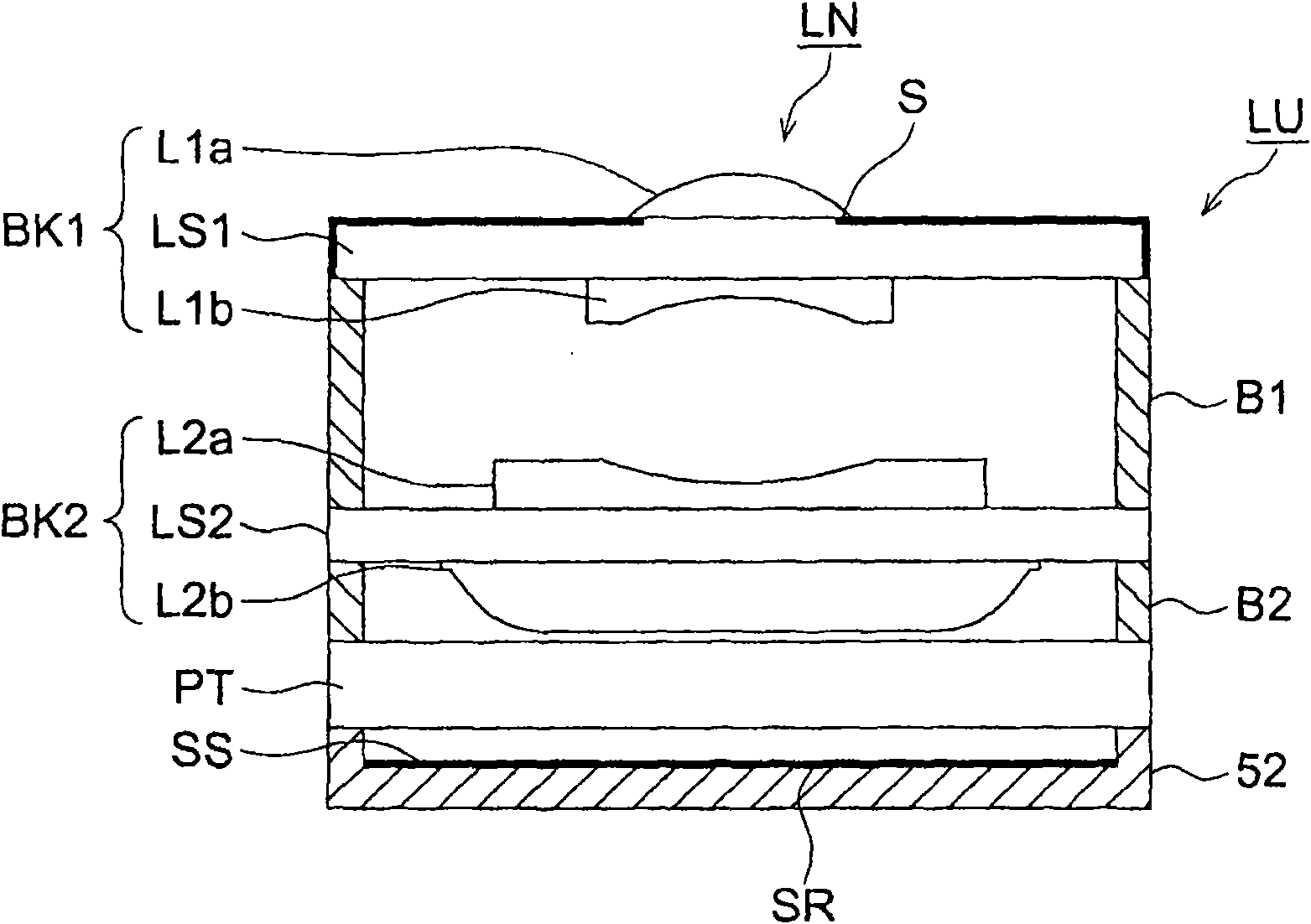

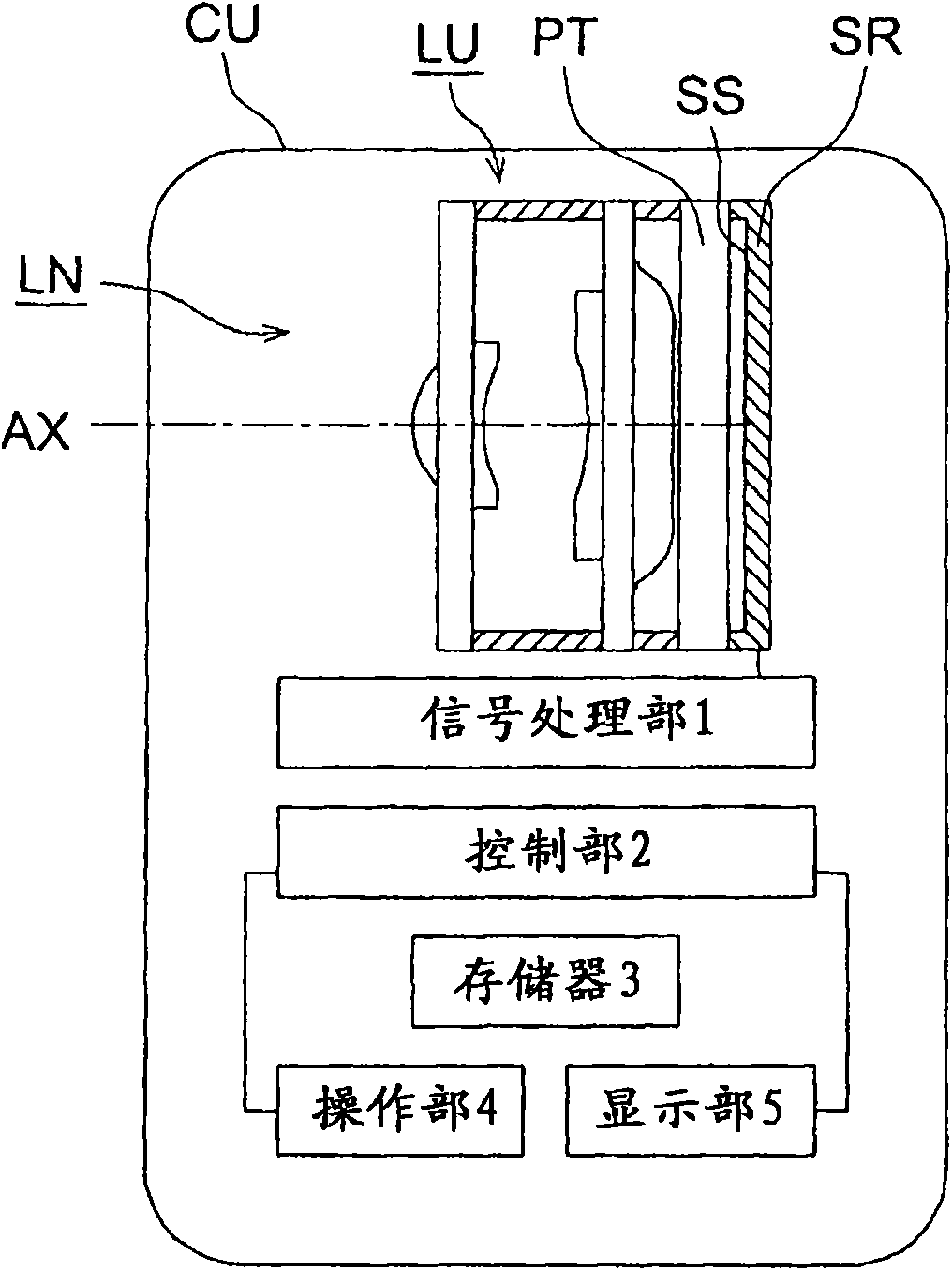

Image

Examples

Embodiment 1

[0217] The system data is as follows:

[0218] f=2.98mm

[0219] fB=0.16mm

[0220] F=2.8

[0221] 2Y=3.5mm

[0222] ENTP=0.22mm

[0223] EXTP=-1.80mm

[0224] H1=-1.33mm

[0225] H2=-2.82mm.

[0226] The surface data is as follows:

[0227]Surface No. R(mm) D(mm) Nd vd Effective Radius(mm)

[0228] 1(*) 0.825 0.30 1.513 55 0.56

[0229] 2(aperture) ∞ 0.39 1.470 65 0.51

[0230] 3 ∞ 0.07 1.590 30 0.50

[0231] 4(*) 2.307 0.41 0.50

[0232] 5(*) -2.856 0.14 1.570 35 0.58

[0233] 6 ∞ 0.69 1.470 65 0.78

[0234] 7 ∞ 0.49 1.570 35 1.31

[0235] 8(*) 9.805 0.10 1.39

[0236] 9 ∞ 0.50 1.516 64 1.59

[0237] 10 ∞ 0.16 1.71

[0238] The aspheric coefficients are as follows:

[0239] side 1

[0240] K=0.24110E-01, A4=-0.76992E-02, A6=0.22116E+00, A8=-0.89518E+00, A10=0.76286E-01, A12=0.12557E+01, A14=0.14692E+02 , A16=-0.81966E+01, A18=-0.47815E+02, A20=-0.10647E+02

[0241] side 4

[0242] K=0.11699E+02, A4=0.15488E+00, A6=-0.22486E+00, A8=0.54011E+00, A10=0.941...

Embodiment 2

[0264] The system data is as follows:

[0265] f=2.93mm

[0266] fB=0.07mm

[0267] F=2.78

[0268] 2Y=3.5mm

[0269] ENTP=0.57mm

[0270] EXTP=-1.75mm

[0271] H1=-1.22mm

[0272] H2=-2.86mm.

[0273] The surface data is as follows:

[0274] Surface No. R(mm) D(mm) Nd vd Effective Radius(mm)

[0275] 1(*) 0.783 0.33 1.518 57 0.57

[0276] 2 ∞ 0.30 1.520 62 0.52

[0277] 3(aperture) ∞ 0.06 1.572 35 0.40

[0278] 4(*) 1.814 0.35 0.44

[0279] 5(*) -3.460 0.11 1.572 35 0.57

[0280] 6 ∞ 1.10 1.520 62 0.69

[0281] 7 ∞ 0.41 1.572 35 1.37

[0282] 8(*) 9.576 0.10 1.45

[0283] 9 ∞ 0.50 1.470 65 1.60

[0284] 10 ∞ 0.07 1.72

[0285] The aspheric coefficients are as follows:

[0286] side 1

[0287] K=-0.30420E+00, A4=0.61331E-01, A6=0.52666E+00, A8=-0.63008E+00, A10=-0.56268E+00, A12=0.60414E+01

[0288] side 4

[0289] K=0.50116E+01, A4=0.30772E+00, A6=-0.15497E+01, A8=0.25529E+02, A10=-0.11225E+03, A12=0.26608E+03

[0290] side 5

[0291] K=-0.13614E+02, A4...

Embodiment 3

[0310] The system data is as follows:

[0311] f=3.04mm

[0312] fB=0.16mm

[0313] F=2.88

[0314] 2Y=3.5mm

[0315] ENTP=0.18mm

[0316] EXTP=-1.84mm

[0317] H1=-1.39mm

[0318] H2=-2.88mm.

[0319] The surface data is as follows:

[0320] Surface No. R(mm) D(mm) Nd vd Effective Radius(mm)

[0321] 1(*) 0.845 0.25 1.513 55 0.55

[0322] 2 ∞ 0.30 1.470 65 0.51

[0323] 3(aperture) ∞ 0.17 1.610 29 0.50

[0324] 4(*) 2.231 0.49 0.50

[0325] 5(*) -4.276 0.17 1.572 35 0.63

[0326] 6 ∞ 0.88 1.470 65 0.81

[0327] 7 ∞ 0.33 1.700 36 1.39

[0328] 8(*) 8.194 0.10 1.46

[0329] 9 ∞ 0.50 1.516 64 1.58

[0330] 10 ∞ 0.16 1.70

[0331] The aspheric coefficients are as follows:

[0332] side 1

[0333] K=-0.18642E-01, A4=0.42482E-01, A6=-0.11195E+00, A8=0.13865E+01, A10=-0.52066E+01, A12=0.89294E+01

[0334] side 4

[0335] K=0.27654E+01, A4=0.31830E-01, A6=0.42787E+01, A8=-0.33891E+02, A10=0.14295E+03, A12=-0.18868E+03

[0336] side 5

[0337] K=-0.16316E+02, A4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com