Preparation method of heterogeneous catalyst of organic coordination compounds of mesoporous structure metals

A technology of coordination compounds and heterogeneous catalysts, applied in organic compound/hydride/coordination complex catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. The changes of the central microenvironment and the increase of steric hindrance can achieve the effect of high-efficiency and long-lasting catalytic activity, increase the speed of chemical reaction, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of mesoporous metal-organic coordination compound heterogeneous catalyst:

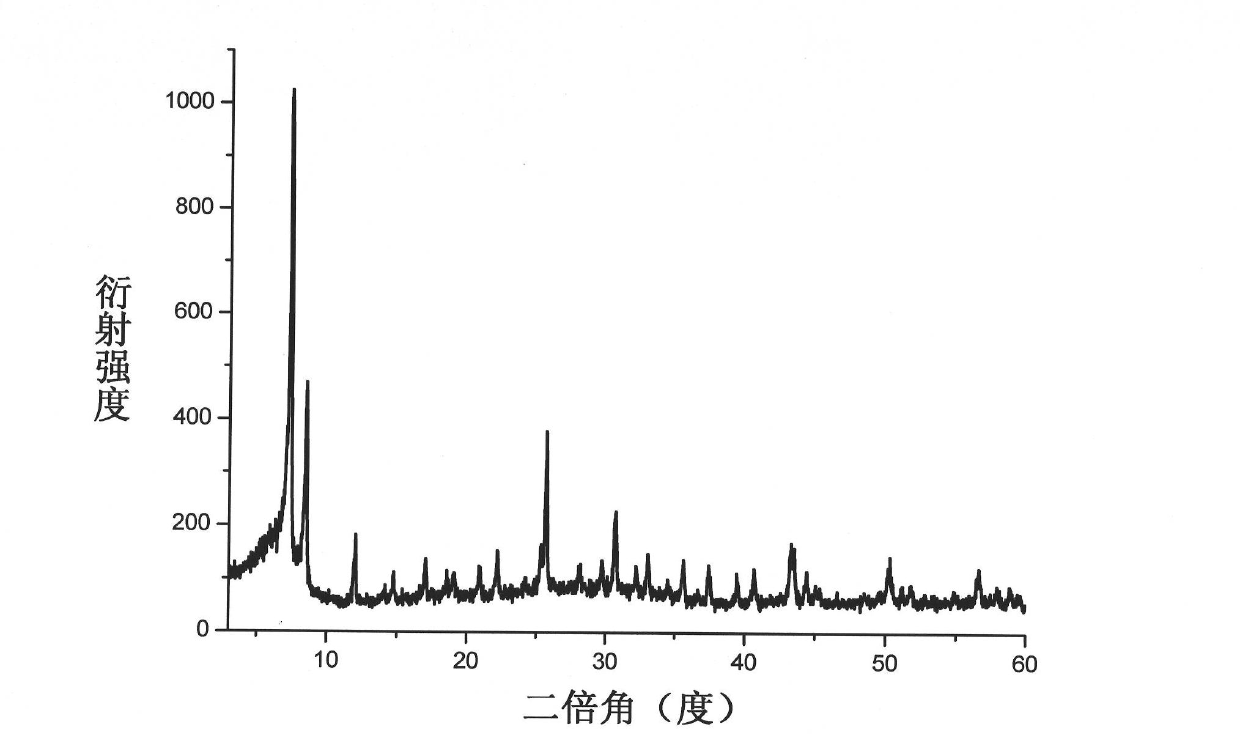

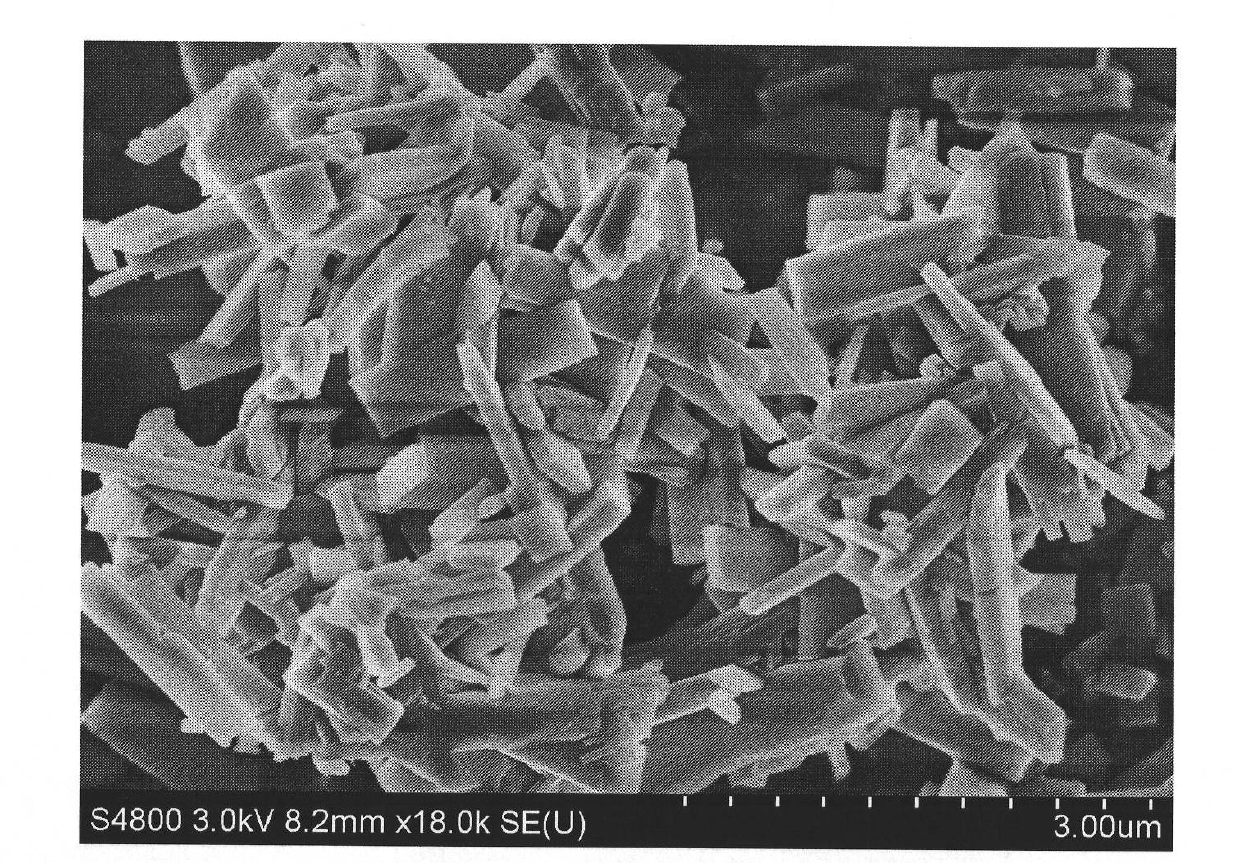

[0035] 0.33g ZrCl 4 Dissolved in 6ml DMF; 0.20g H 2 BDC was dissolved in 6ml of DMF; the two solutions were mixed and stirred at 25°C for 0.5h. Then the mixed solution was transferred to MDS-6 polytetrafluoroethylene microwave reactor, and reacted for 4mins under the condition of 400W. The reactor was taken out and naturally cooled to room temperature, then filtered and washed with DMF; dried in a vacuum oven at 160°C for 24 hours; a white solid catalyst Zr-MOF was obtained.

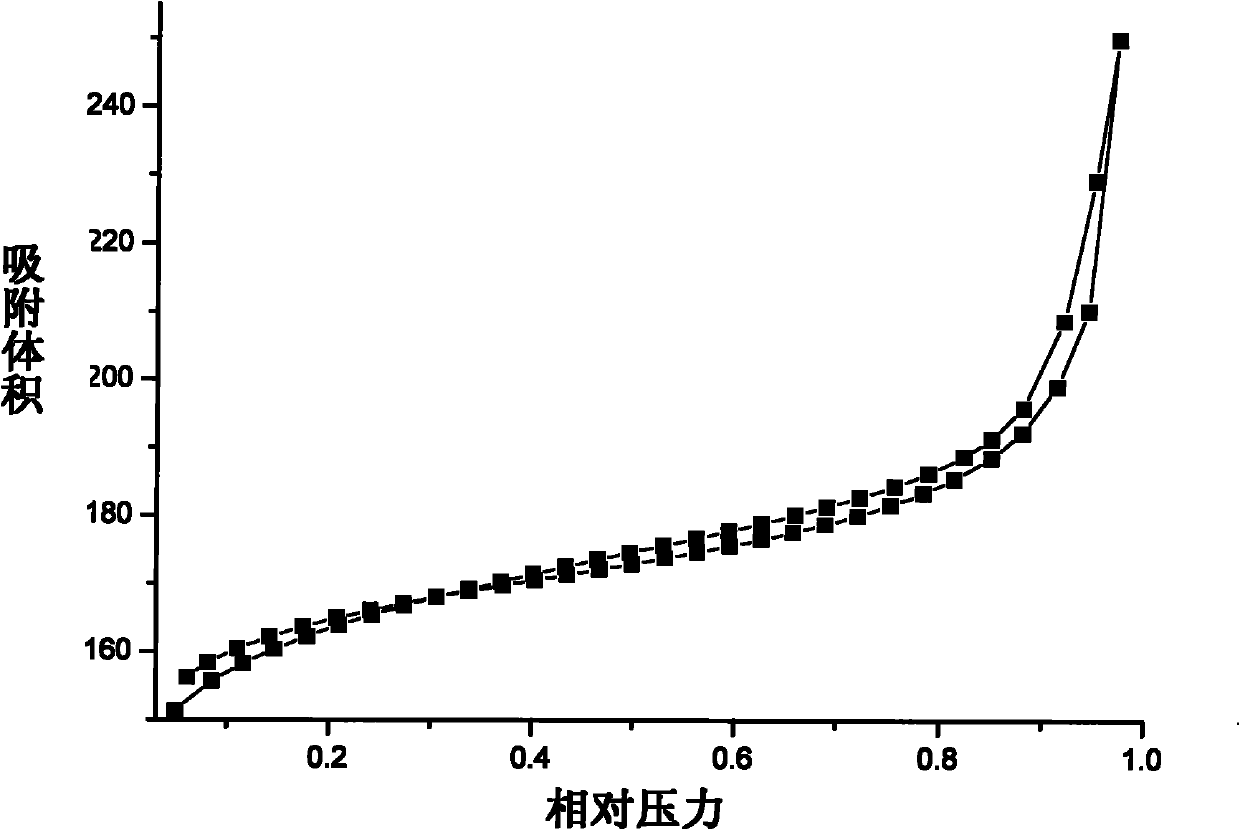

[0036] The structural parameters of the Zr-MOF catalyst determined by the BET method are listed in the following table:

[0037] S BET (m 2 / g)

[0038] The catalyst Zr-MOF is applied to the formation reaction process of flavonoids under solvent-free conditions as follows:

[0039] Add 1.0mmol phlorotriphenol, 1.2mmol ethyl acetoacetate, 0.05g catalyst Zr-MOF to a 10ml round bottom ...

Embodiment 2

[0043] 0.66g ZrCl 4 Dissolved in 12ml DMF; 0.40g H 2 BDC was dissolved in 12 ml DMF; the two solutions were mixed. Stir at 25°C for 0.5h, then transfer the mixed solution to a polytetrafluoroethylene MDS-6 microwave reactor, and react at 400W for 4mins. The reactor was taken out and naturally cooled to room temperature, then filtered, washed with DMF, and dried in a vacuum oven at 160°C for 24 hours to obtain a white solid catalyst Zr-MOF. The structural parameters of the Zr-MOF catalyst determined by the BET method are listed in the following table:

[0044] S BET (m 2 / g)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com