Application of double-layer aseptic technique in outer package of large capacity injection

An aseptic technology and large-capacity technology, applied in packaging, packaged food, drug packaging, etc., can solve problems such as increasing the cost of disinfection for medical staff, failing to meet the requirements of aseptic grades, and unable to fully guarantee the health and safety of patients. Achieve the effect of ensuring good health, reducing medical accidents and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

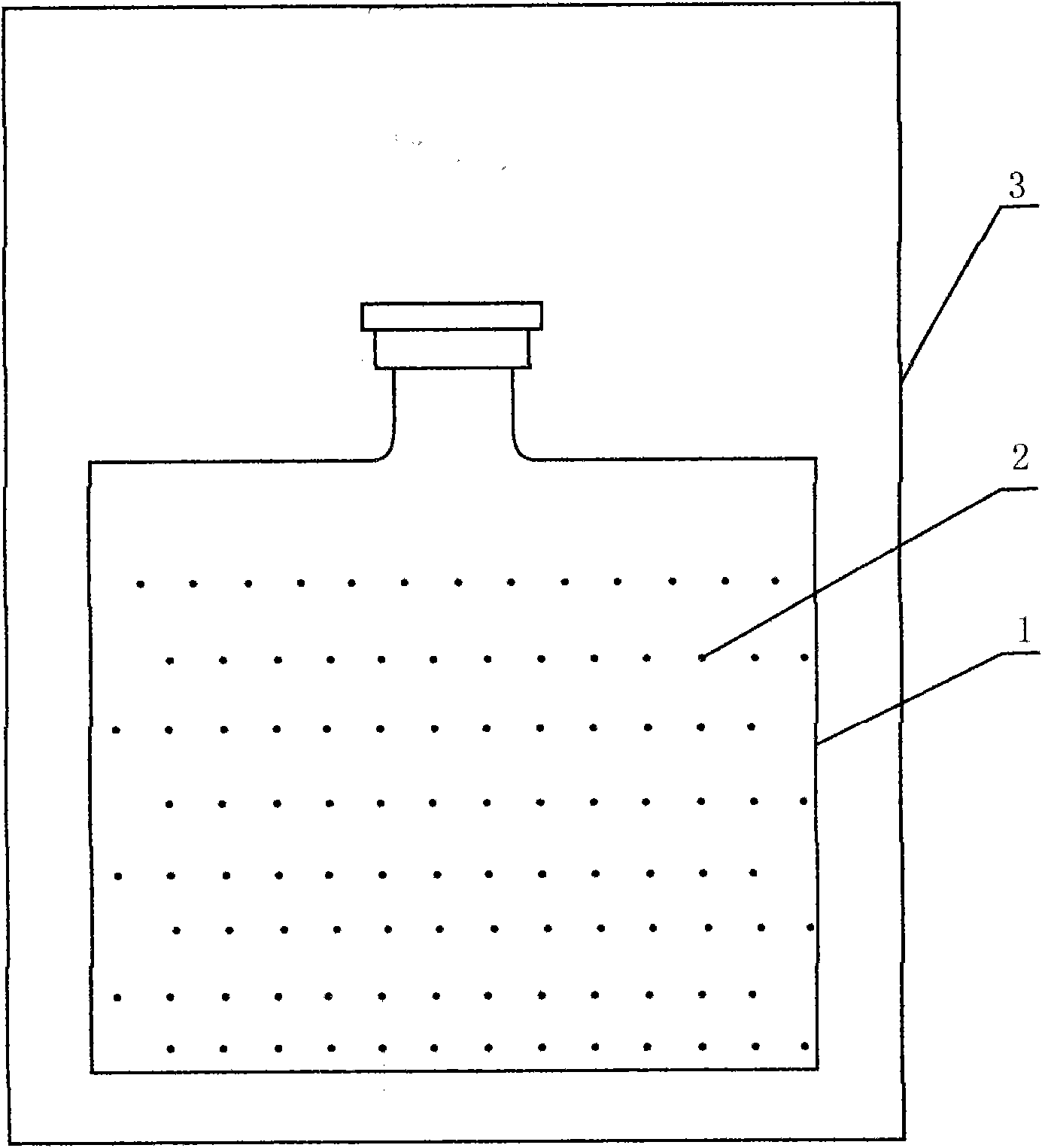

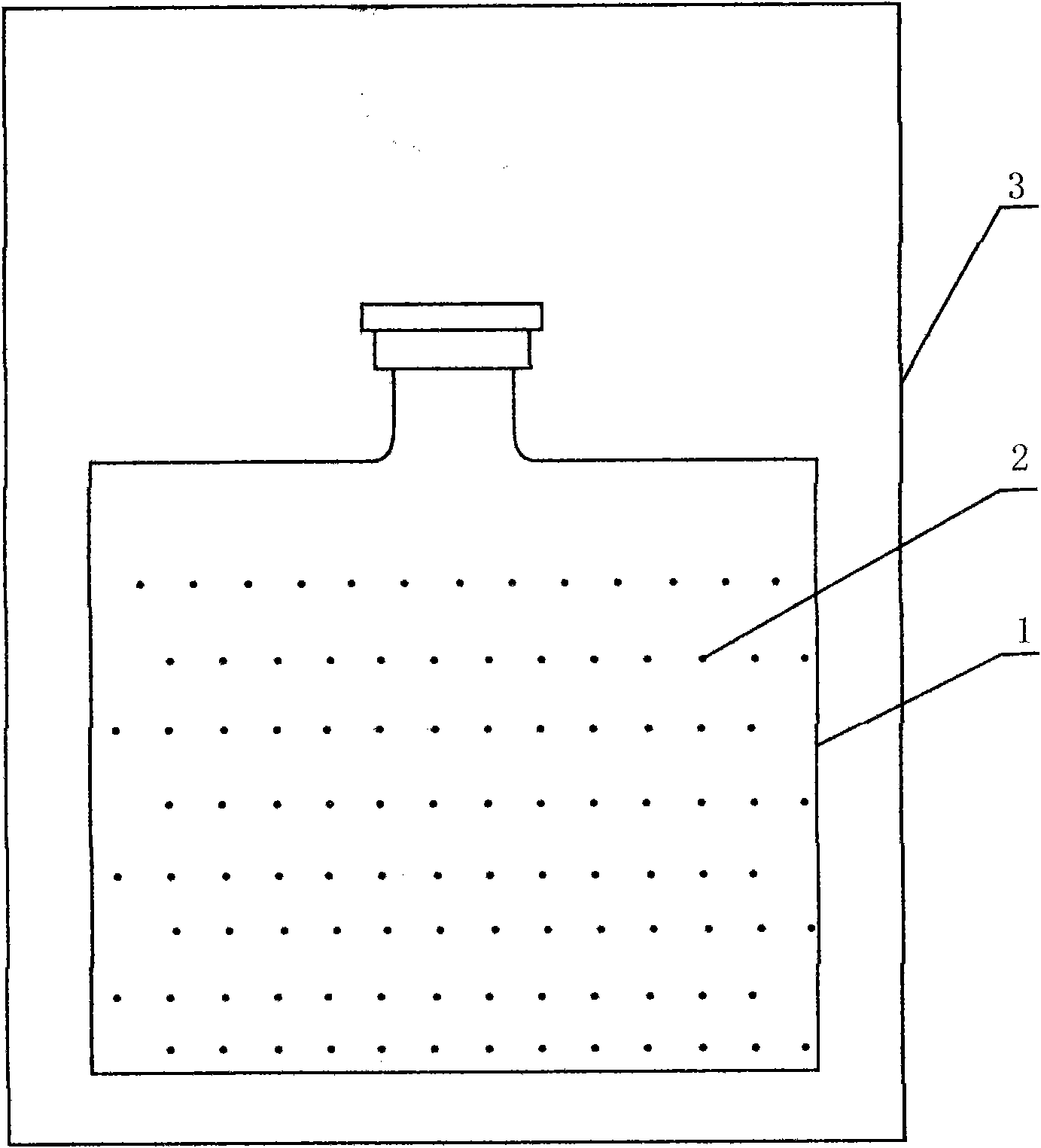

[0018] Taking the non-PVC soft bag infusion bag as an example, the packaging of large-capacity injections is carried out according to the following process:

[0019] Step 1: Cut the inner packaging bag in the aseptic workshop, and fill the inner packaging with liquid medicine to form a large-capacity injection.

[0020] Step 2: Pack the filled large-capacity injection into the protective outer packaging 3, and this process is also carried out in the aseptic workshop.

[0021] The third step: seal the protective outer packaging 3 completely, and this process is also carried out in the aseptic workshop.

[0022] Step 4: Put the large-capacity injection into the sterilization device for sterilization. The sterilization temperature is 121 degrees Celsius, and the duration is 20 to 30 minutes.

[0023] Step 5: Dry the sterilized large-volume injection, and then enter the follow-up process, such as passing the inspection.

[0024] Step 6: Pack the qualified large-volume injections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com