High-temperature low-oxygen top-combustion-type air heating furnace

A high-temperature, low-oxygen combustion, high-temperature, low-oxygen technology, applied to brick blast furnaces, etc., can solve problems such as intergranular stress corrosion of the furnace shell, pollute the environment, and accelerate production, and achieve improved heat transfer efficiency, increased flame volume, and NOX The generation-inhibiting effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

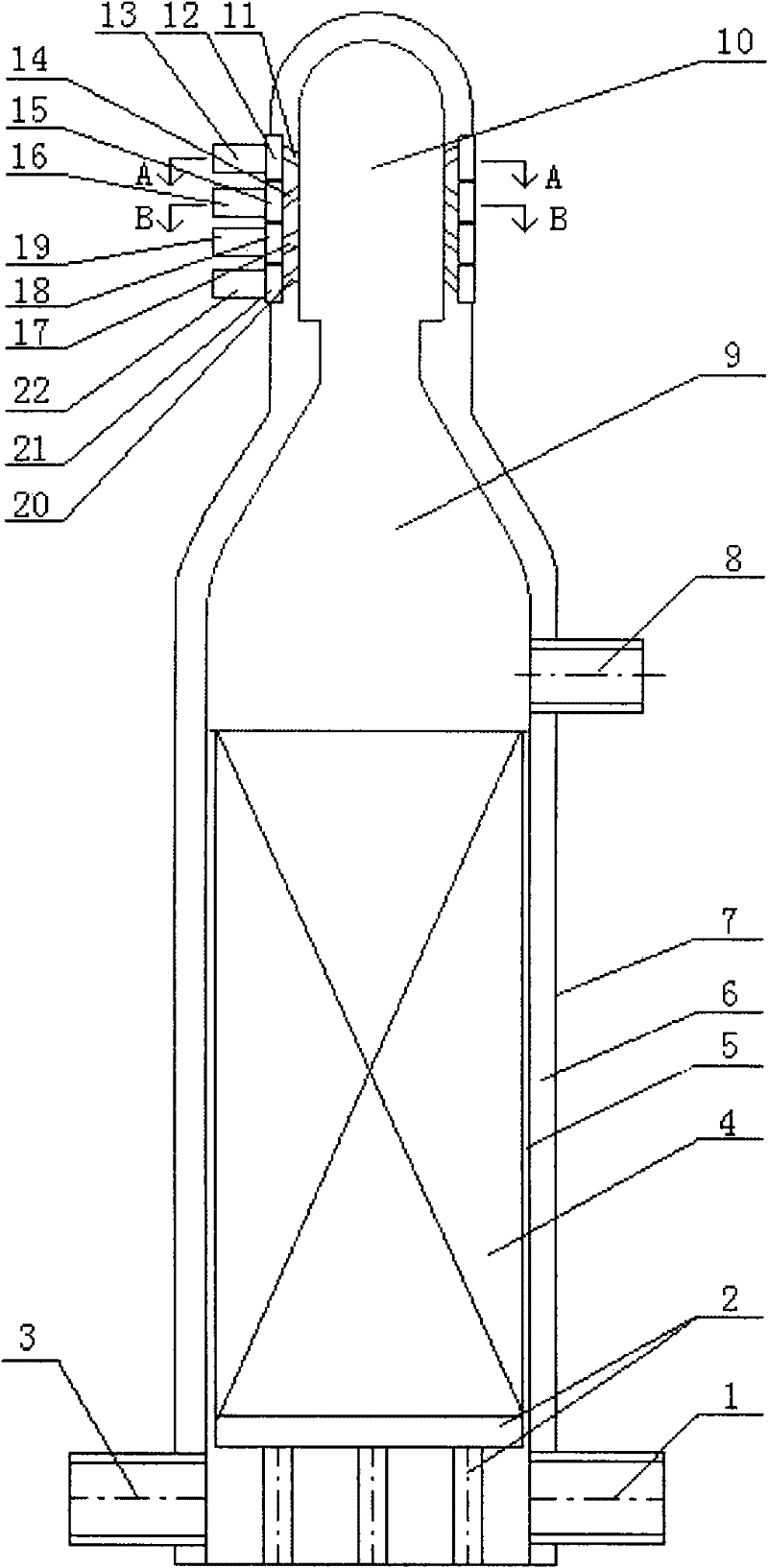

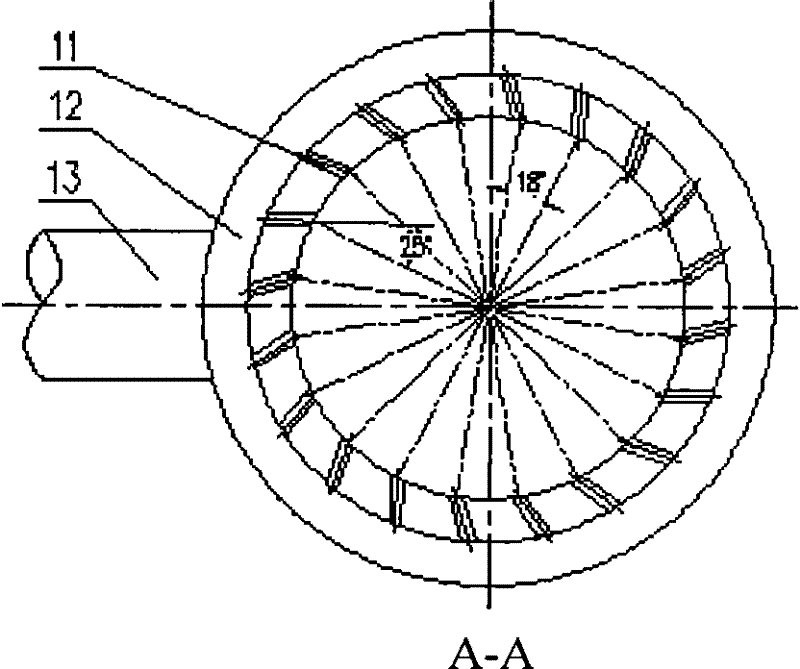

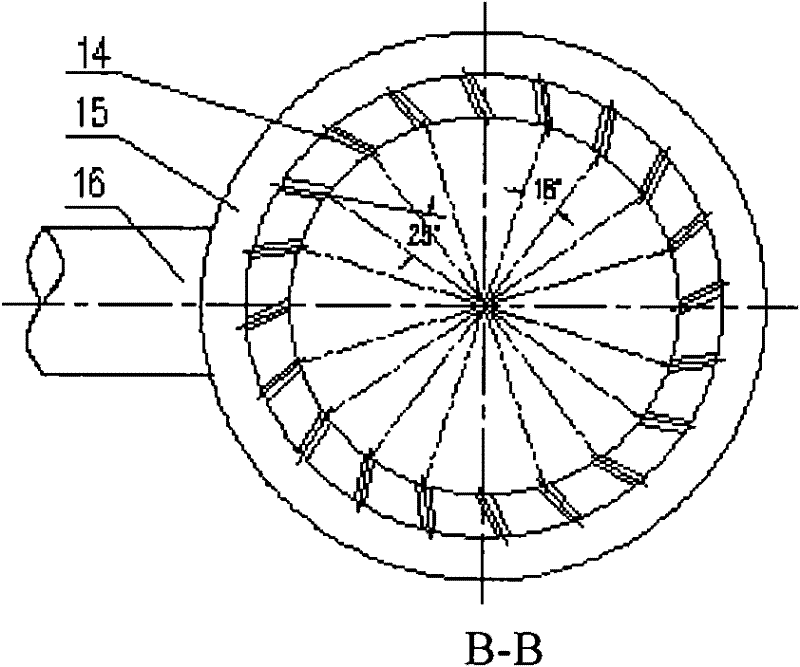

[0022] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention. Such as figure 1As shown in the structural diagram of the embodiment of the present invention, the high-temperature low-oxygen top-fired hot blast stove consists of a cold air inlet 1, a furnace grate and a pillar 2, a flue gas outlet 3, a checker brick 4, a regenerator 5, a furnace lining 6, and a furnace shell 7. Hot air outlet 8, combustion chamber 9, high temperature low oxygen burner 10 layers. Wherein the high-temperature low-oxygen burner 10 is composed of the first layer of gas nozzle 11, the first layer of gas ring 12, the first layer of gas inlet 13, the first layer of air nozzle 14, the first layer of air ring 15, the first layer of air inlet 16. The second layer of air nozzles 17, the second layer of air rings 18, the second layer of air inlets 19, the second layer of gas nozzles 20, the second layer of gas rings 21, and the second layer of gas inlets 22.

[0023] Depend on figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com