Arch-included integral pushing method for large-tonnage multi-span combined arch bridge

A large-tonnage, integrated technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large cantilever jacking and weak force of combined arch bridges, and achieve high safety, low construction cost and clear force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

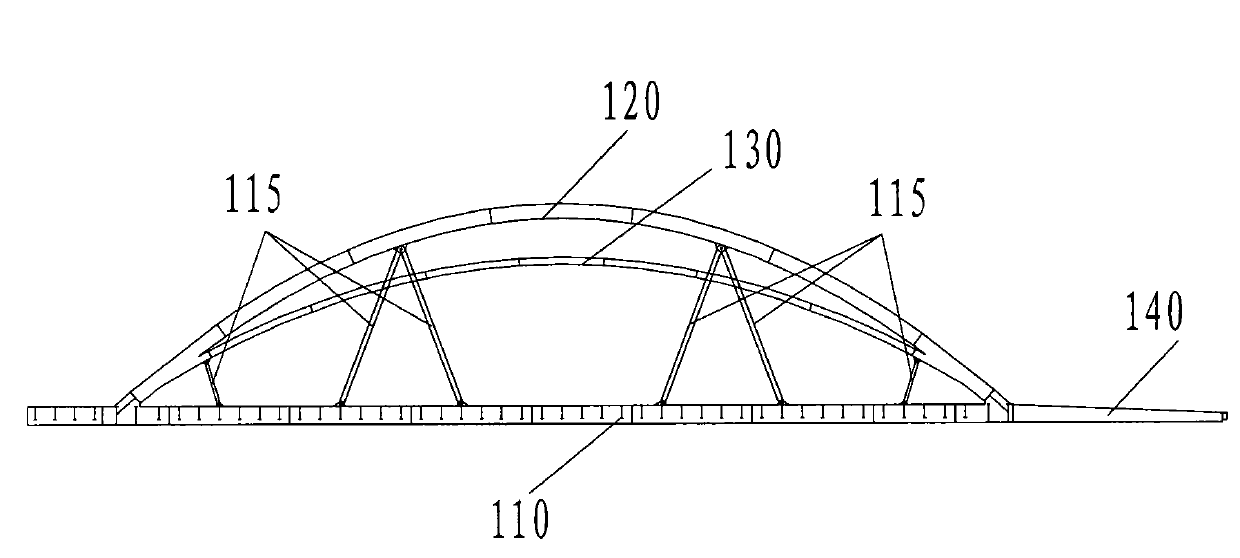

[0038] Before explaining the technical aspects of the present invention, firstly, the related devices for realizing the method of the present invention are described, so as to facilitate the understanding of the present invention.

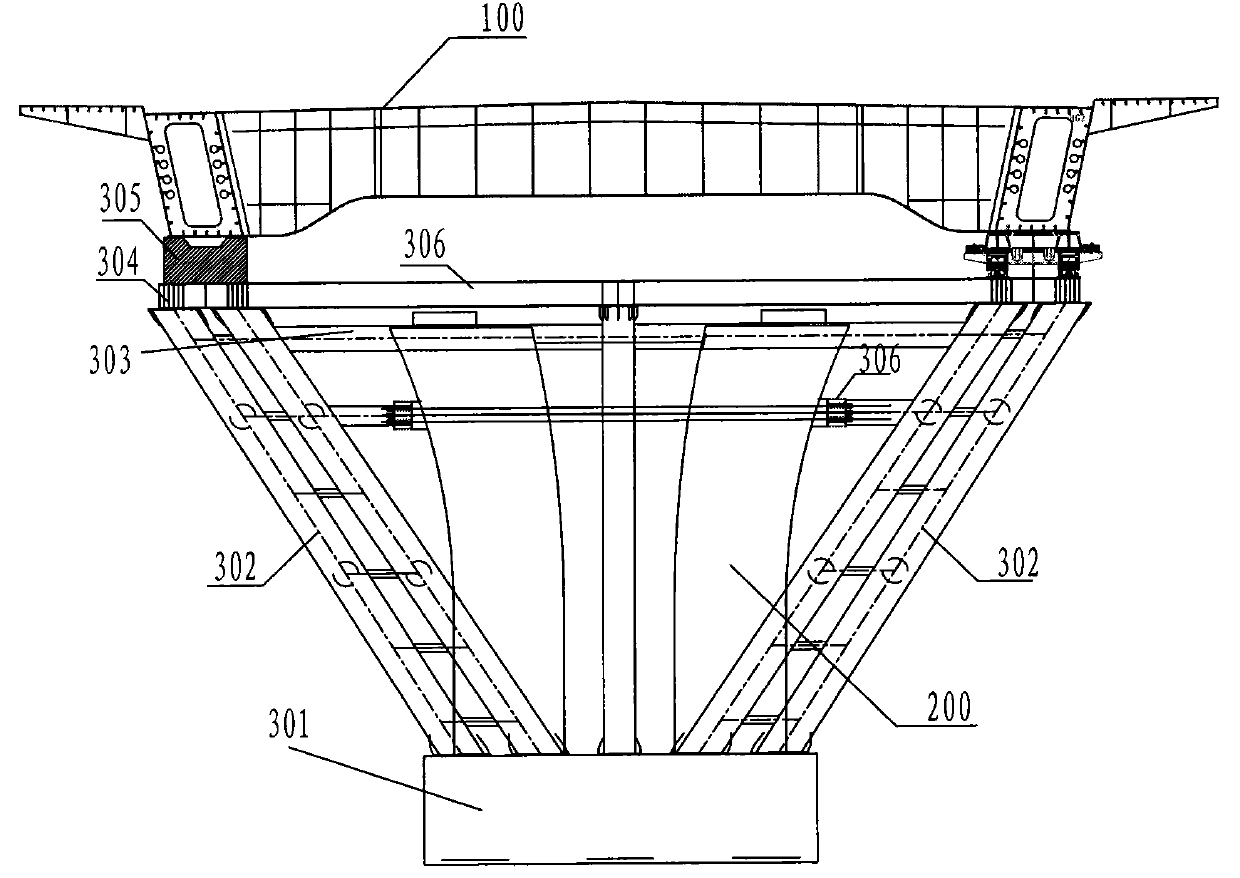

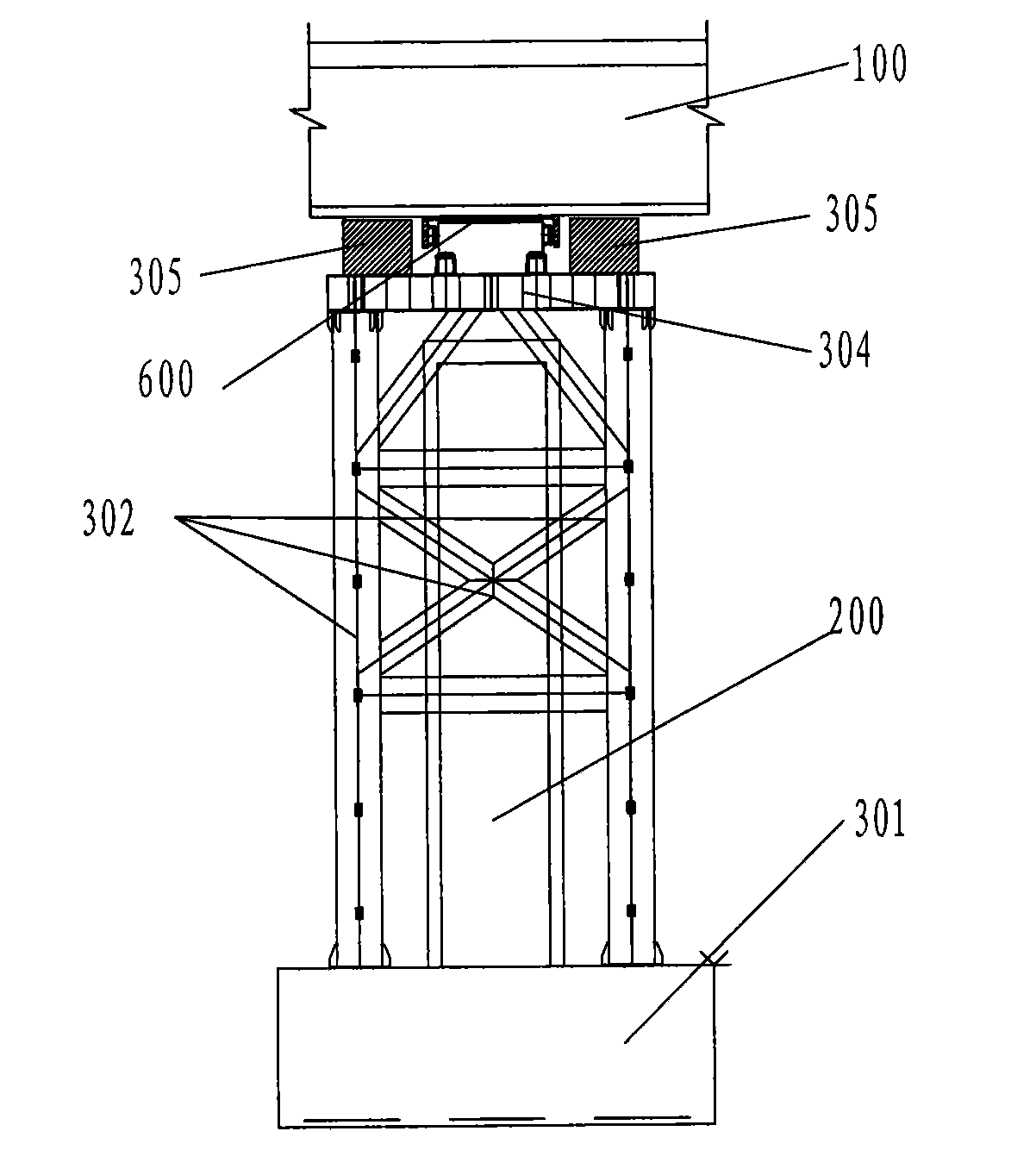

[0039] During the pushing process, it is necessary to support the main longitudinal beam and the walking translational pushing device. On the three structural piers 200 close to the multi-span steel arch beam assembly tool platform 100, side supports 300 are provided.

[0040] The structure of the support 300 next to the pier is as follows figure 1 As shown, two support frames 302 are arranged on both sides of the platform 301 respectively, and the two support frames 302 are arranged in a "V" shape, and a transverse connector 303 is connected between the upper ends of the two support frames. There is a load-bearing beam 304 on which a temporary pad beam 305 is arranged, and a transverse connecting rod 307 is connected between the support frame 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com