Multiple ring electrode array imaging sensor

An imaging sensor, ring electrode technology, applied in the direction of material capacitance, material resistance, etc., can solve the problems of difficult installation of the sensor electrode array, low resolution in the central part of the pipeline, and limited use of the sensor, so as to improve the sensitivity and meet the complex requirements. Measurement requirements, reducing the effect of the "soft field" effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

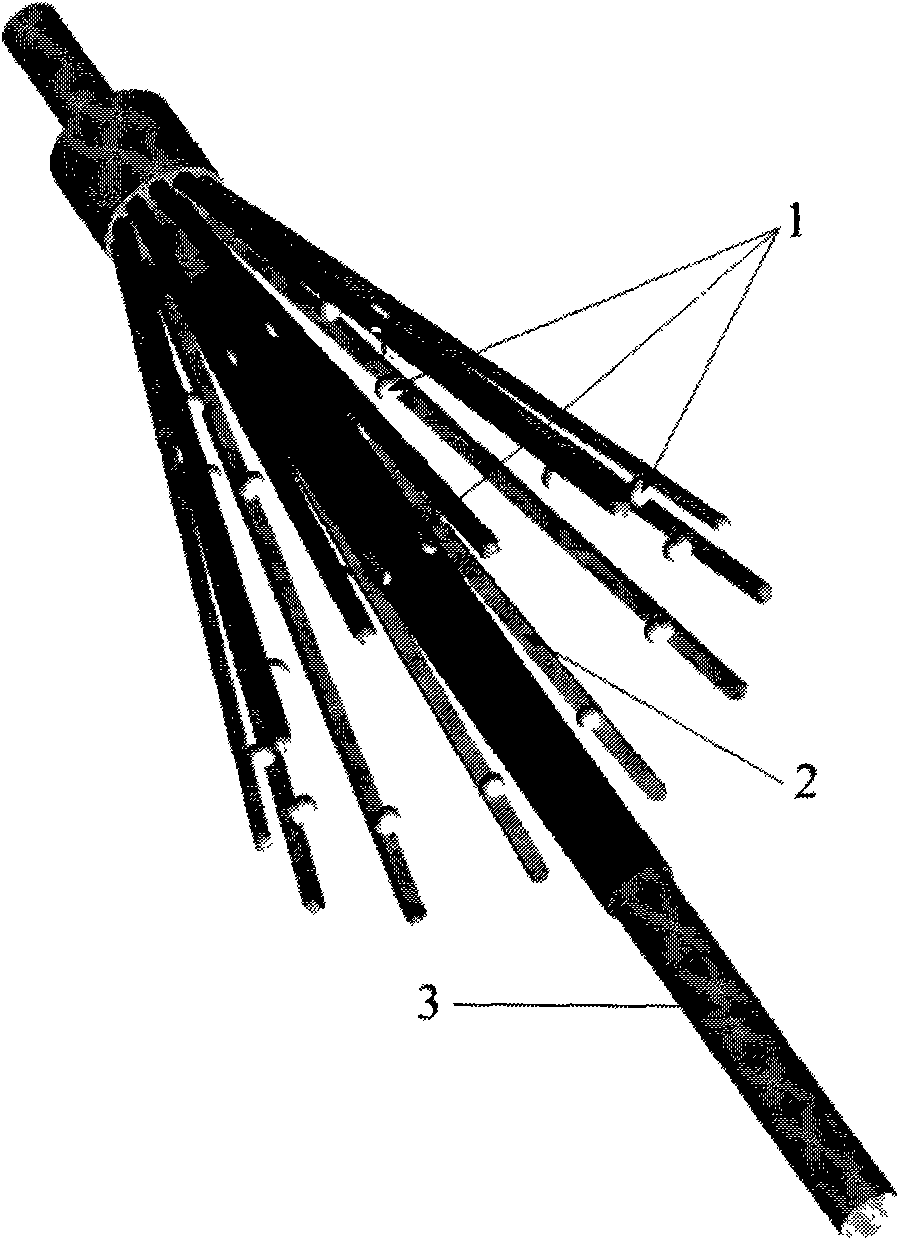

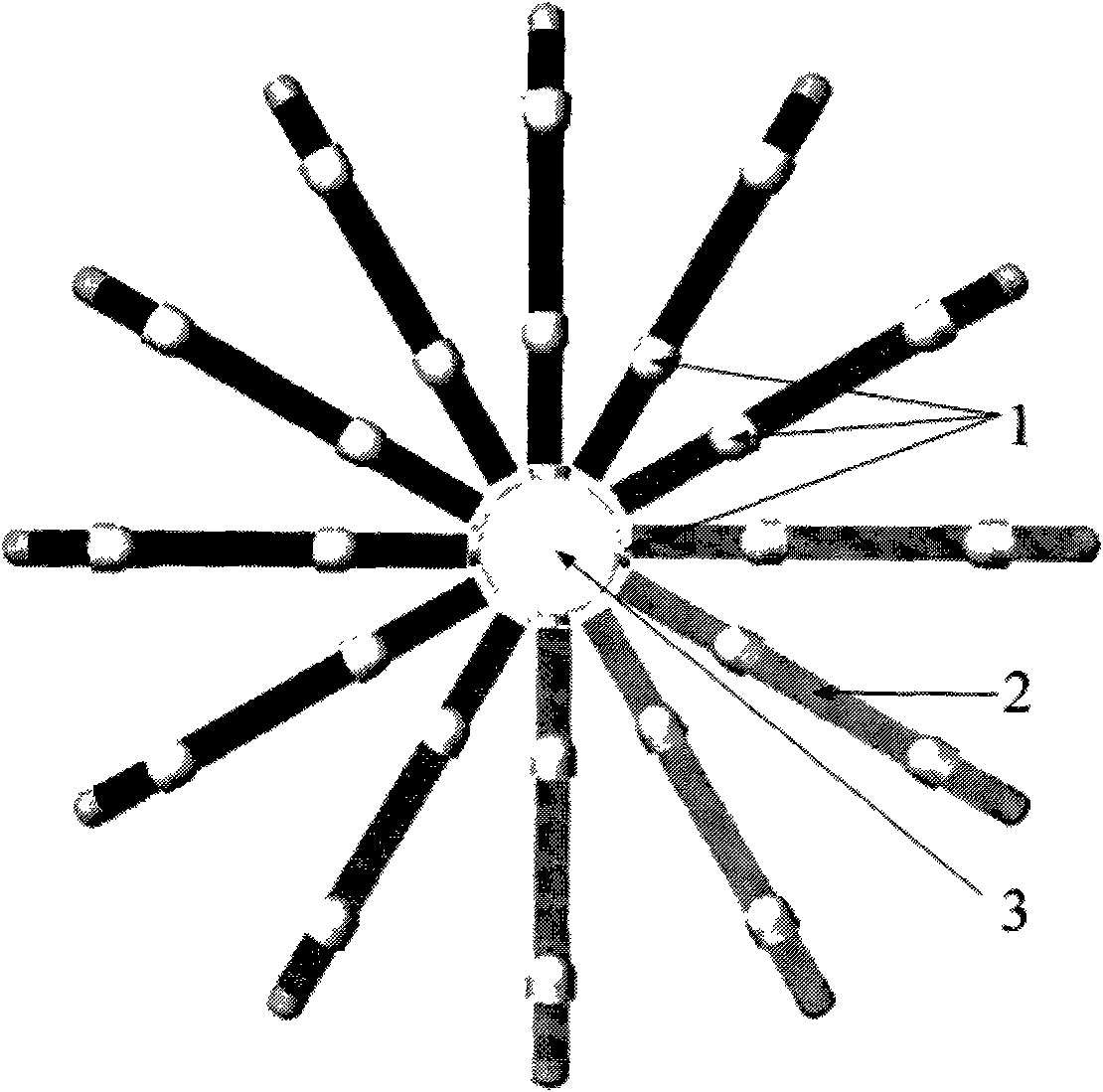

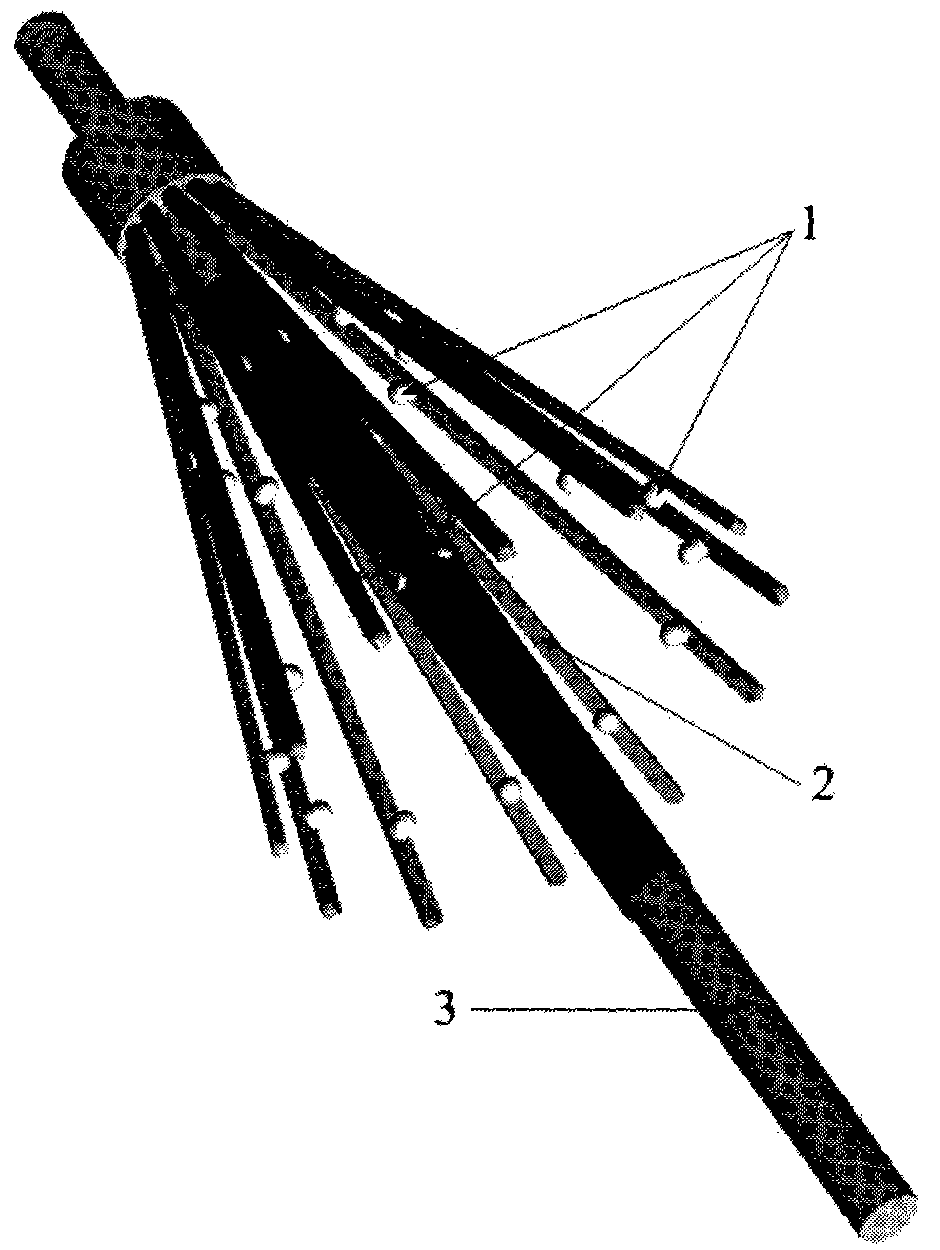

[0022] The specific implementation of a multi-ring electrode array imaging sensor of the present invention will be further described in conjunction with the accompanying drawings:

[0023] A multi-ring electrode array imaging sensor, characterized in that: the sensor intervenes in a two-phase fluid without contacting the inner wall of a measuring pipeline, and its structure includes a measuring electrode (1), a supporting arm (2) and a supporting shaft (3); The support shaft (3) is located at the center of the sensor, the support arm (2) is fixed on the support shaft (3), and extends radially outwards, and is radially distributed on the support shaft (3) in an equiangular manner according to its number M, supporting The angle between the arm (2) and the support shaft (3) is The measuring electrodes (1) are arranged on the support arm (2) and the support shaft (3), and are distributed on different circumferences concentric with the circular cross-section pipeline, and the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com