Transparent conductive material

A technology of transparent conductors and conductive layers, which is applied in the direction of conductive layers on insulating carriers, electronic equipment, and electrical digital data processing. Prevents cracks and abrasions, achieves durability, and achieves sufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

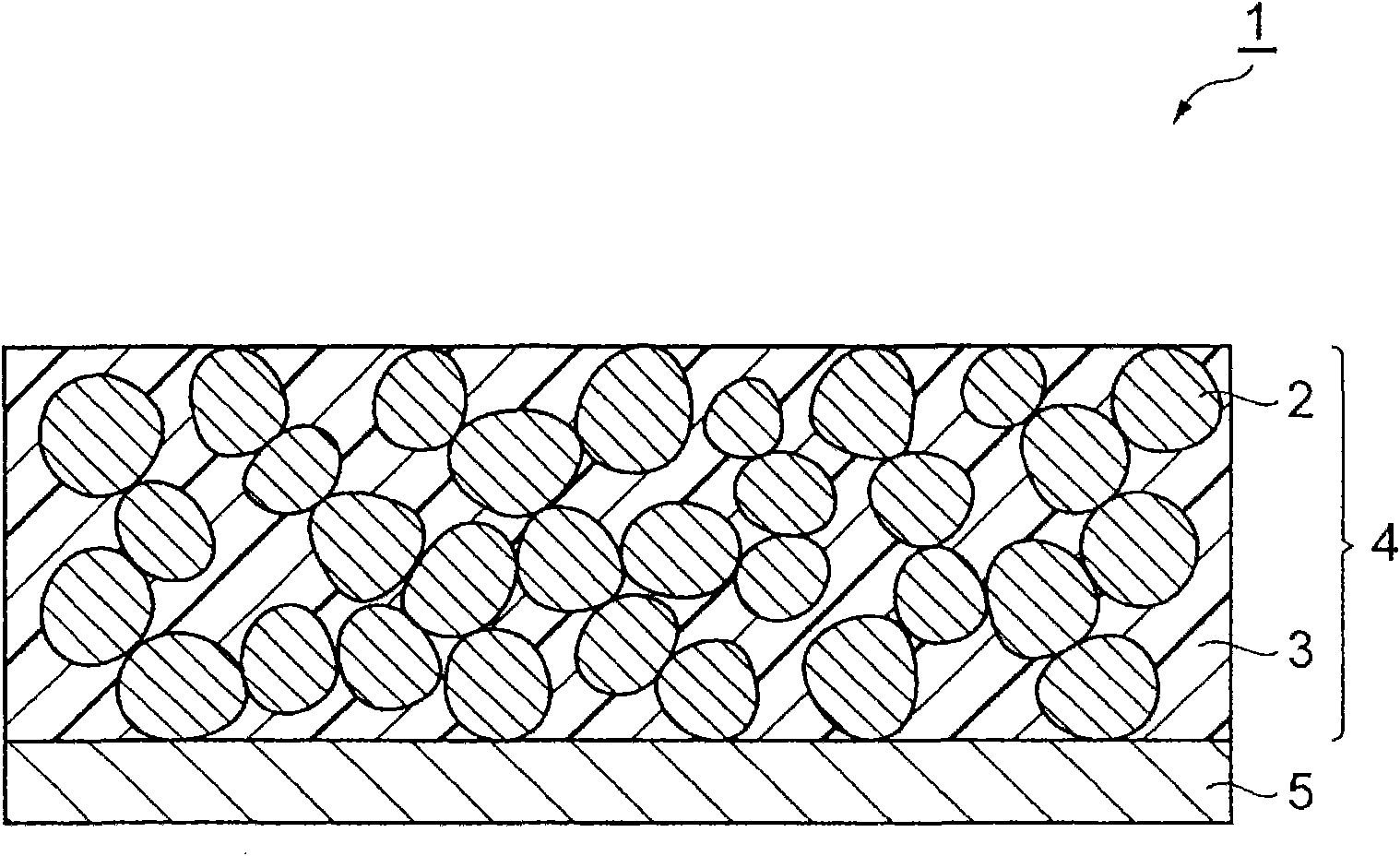

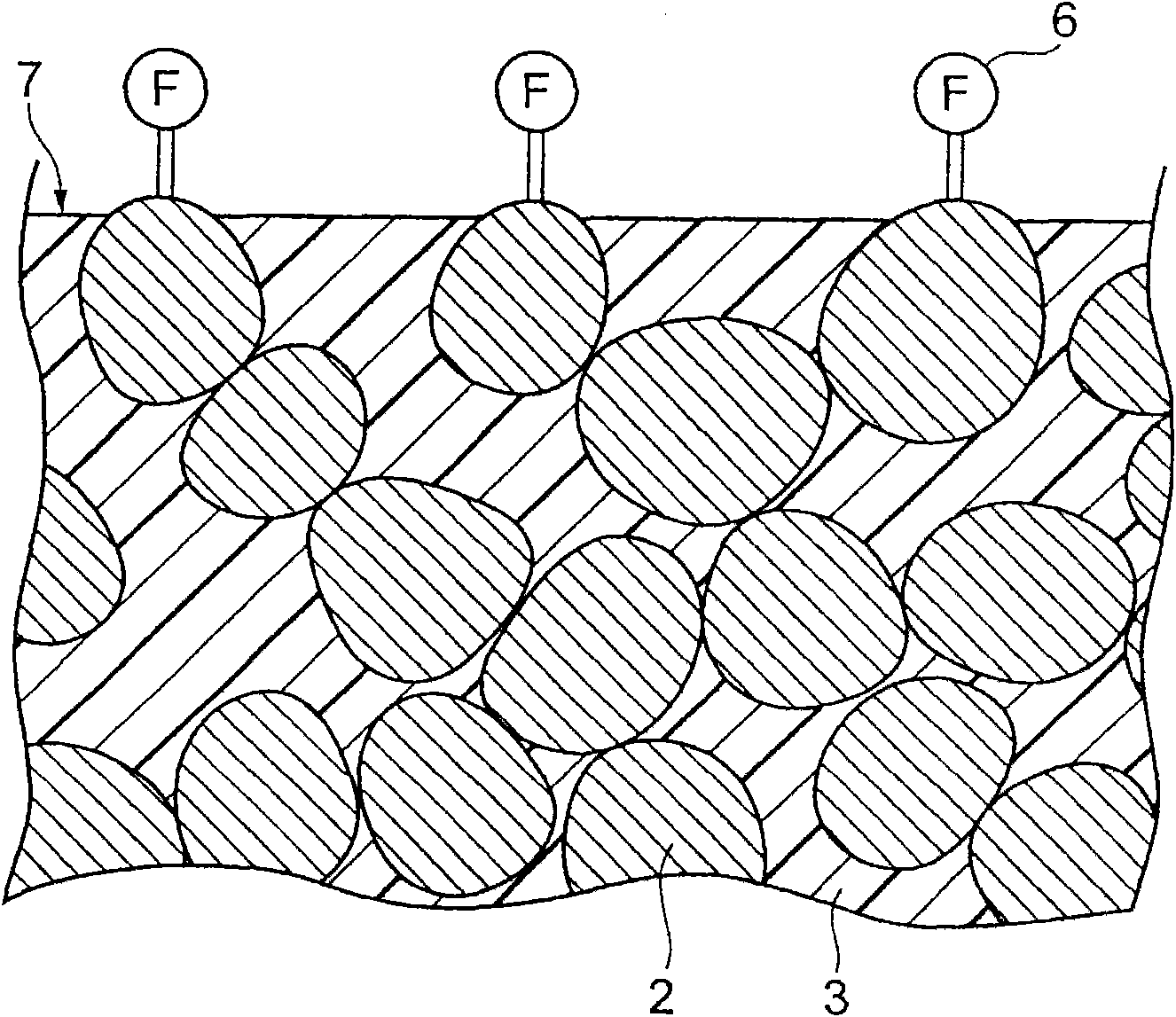

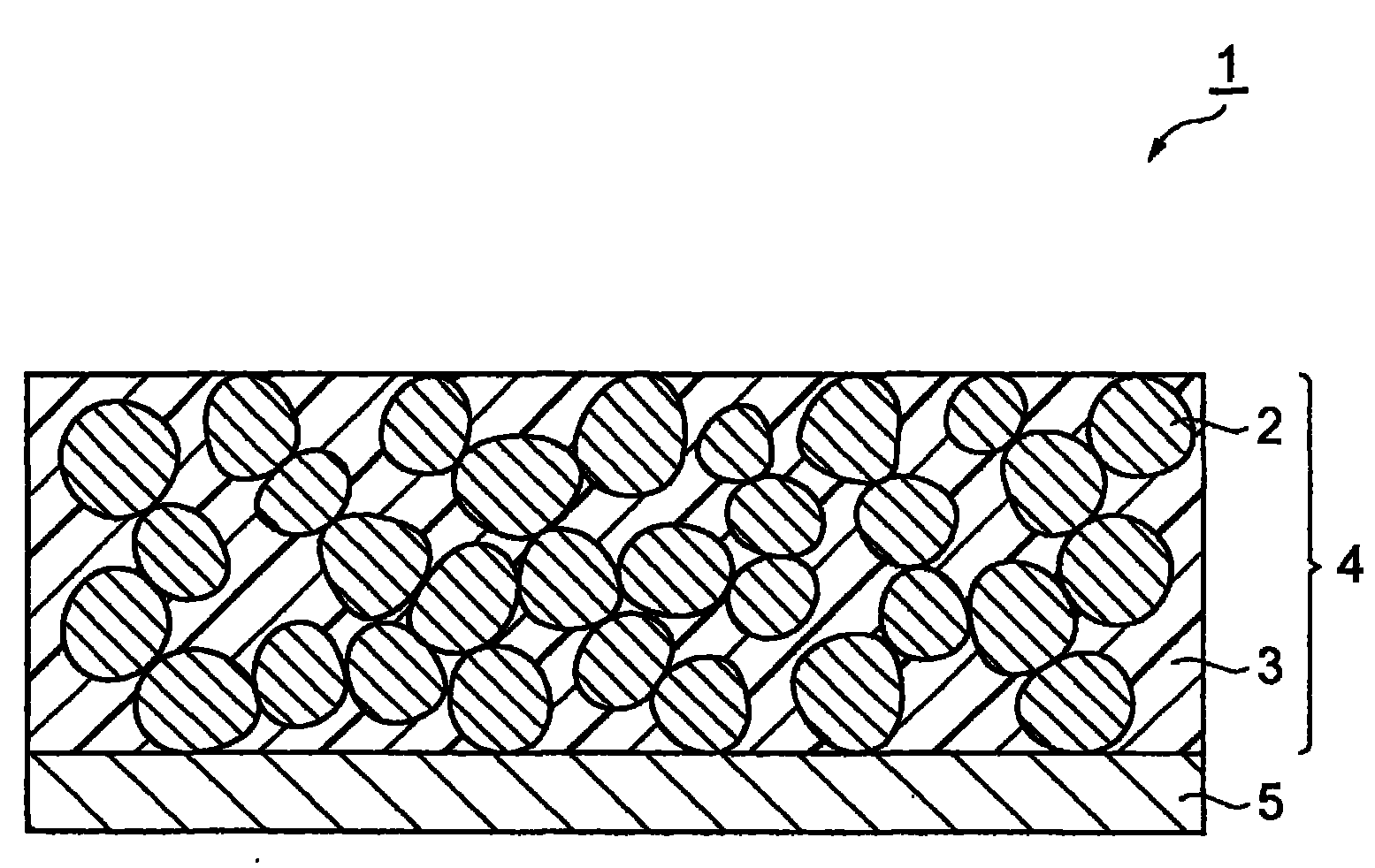

[0074] As a substrate, a polyethylene terephthalate (PET) film (manufactured by TORAY Co., Ltd., thickness: 50 μm) provided with an anchor layer (manufactured by Panasonic Denko Co., Ltd.) in advance was prepared. The ITO dispersion coating solution (the average particle diameter of ITO powder is 30nm, and the solid content concentration is 25%) is coated on this film by bar coating method, and this ITO dispersion coating solution is made of indium oxide doped with tin (hereinafter referred to as "ITO") powder and ethanol. After coating, the ethanol was volatilized, and the ITO powder was fixed on the anchor layer by rolling. Thus, a layer of ITO powder formed by compression on the substrate was formed.

[0075] Next, a solution of the photocurable acrylic resin composition was applied on the layer of the ITO powder by a bar coating method. Here, the solution of the acrylic resin composition was obtained by mixing 20 parts by mass of an acrylic polymer (manufactured by Taise...

Embodiment 2

[0080] A conductive layer was formed in the same manner as in Example 1 above, and after the PET film was peeled off, a fluorinated solvent of 1,1,2,2-tetrahydroperfluorotetradecyltriethoxysilane (manufactured by Gelest) was applied by a bar coating method. The diluted solution (0.05% by mass) was applied on the conductive layer, and the solvent was dried, followed by leaving to stand in an environment of 85° C. and 85% RH for 5 hours. After that, it is immersed in a fluorine solvent to obtain a transparent conductor from which excess fluorine compounds are removed.

Embodiment 3

[0082] Except that the 1,1,2,2-tetrahydroperfluorotetradecyltriethoxysilane (manufactured by Gelest) used in the above Example 2 was changed to 1,1,2,2-tetrahydroperfluoro Except for decyltrichlorosilane, the rest were the same as the above-mentioned Example 2 to prepare a transparent conductor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com