Motor-driven operating mechanism with thermal protector

An electric operating mechanism and protector technology, which is applied to the protection switch operation/release mechanism, the power device inside the switch, etc., can solve the problems of circuit breaker loss, poor size and time control, and burnout of the electric operating mechanism. Small size, saving labor and cost, saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

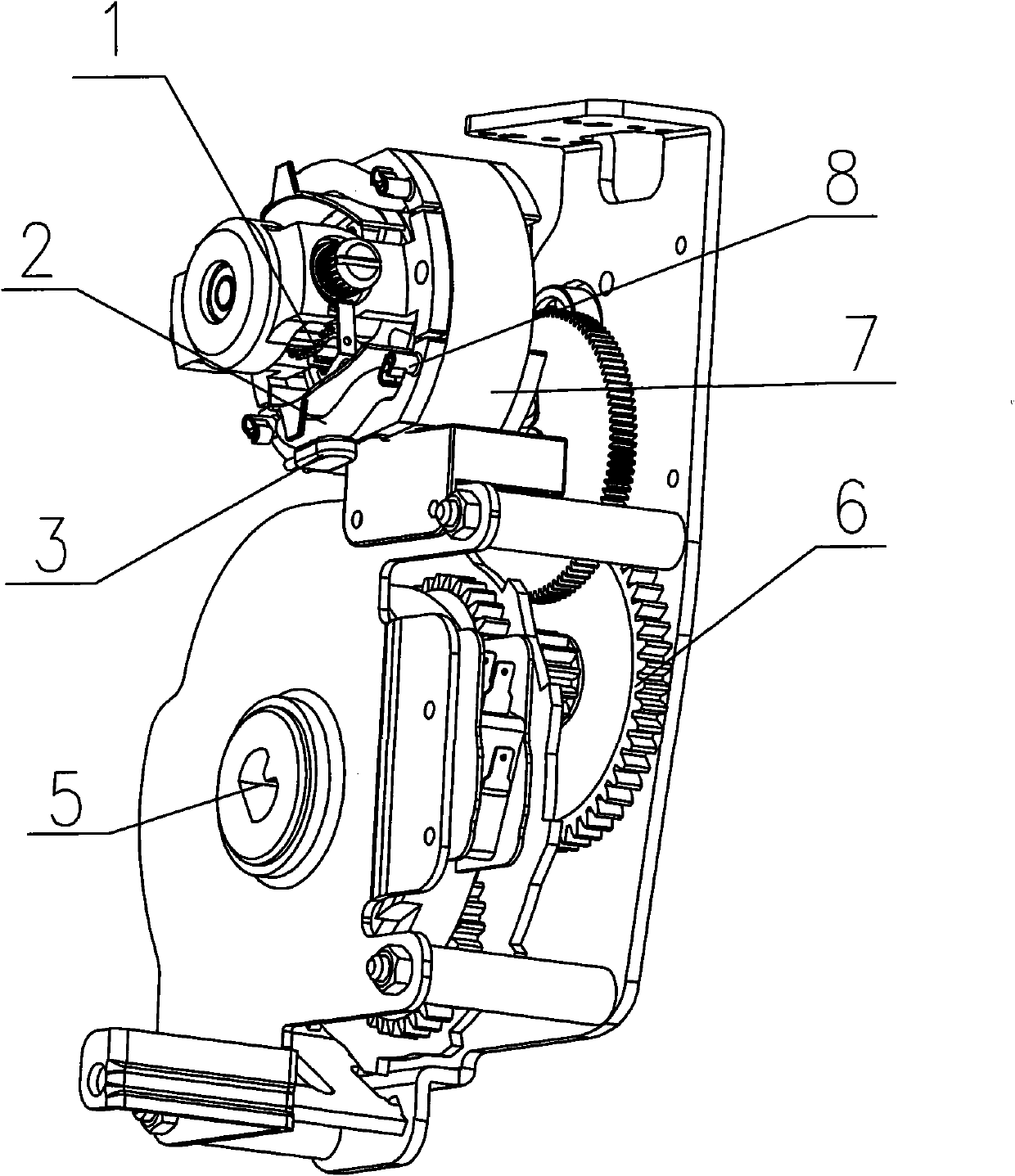

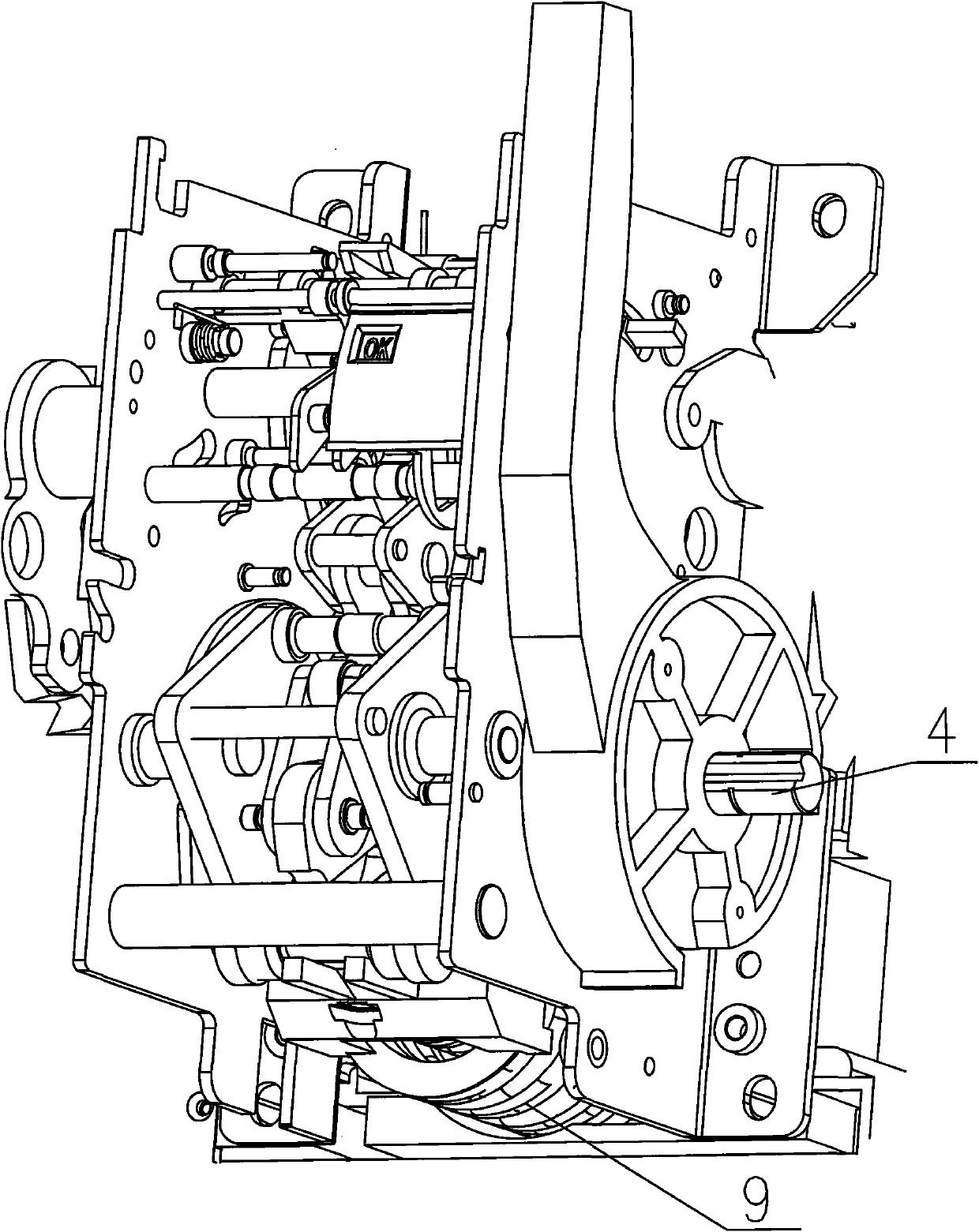

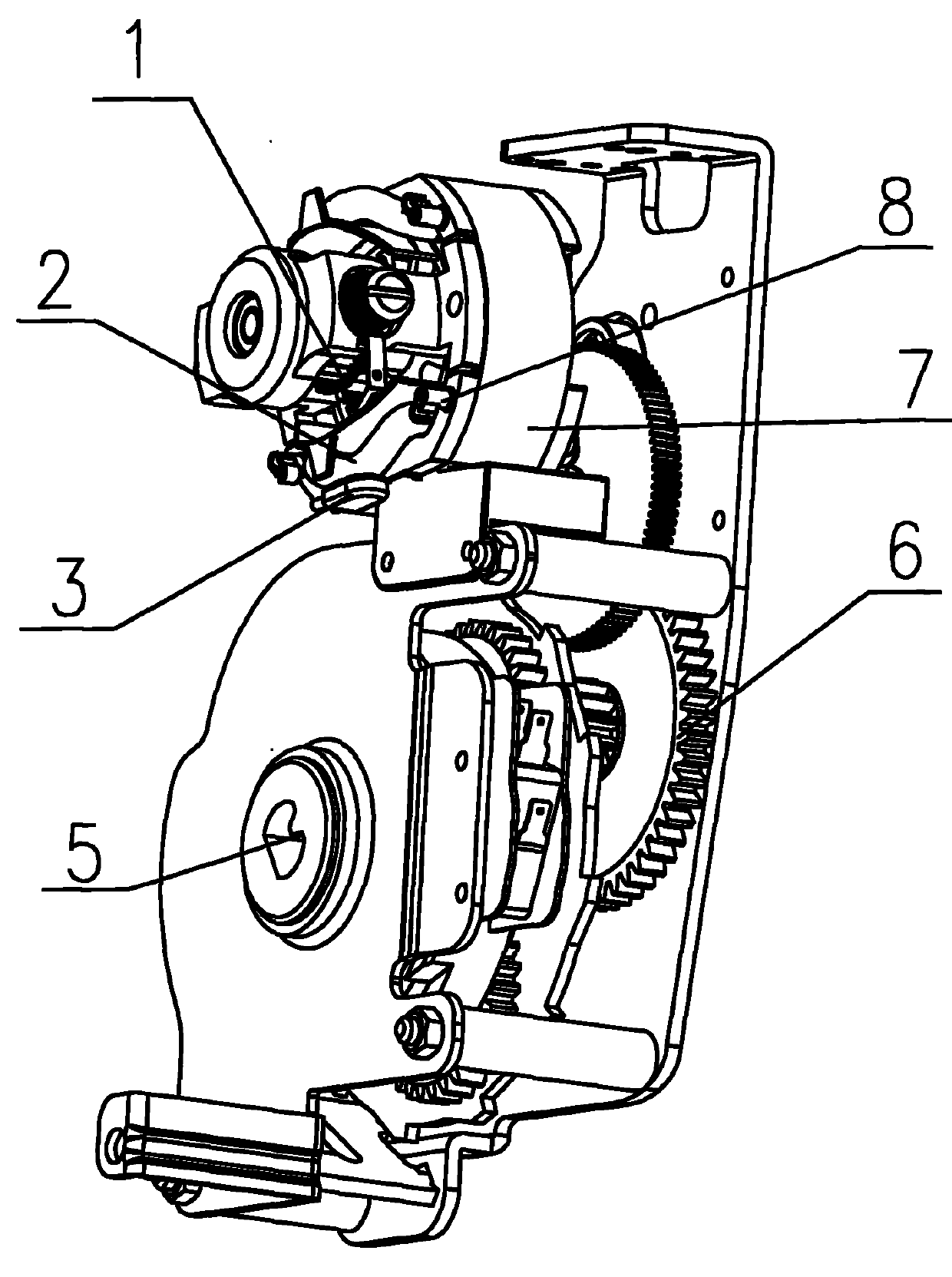

[0015] As shown in the figure: the motor 7 installed in the installation housing, the motor 7 has a motor stator 8 and a motor rotor 1, the motor stator 8 has a stator coil 2, and a reducer 6 and a linkage mechanism are provided in the installation housing, and the reducer 6 It has an output gear 5, the output gear 5 is connected with the main shaft 4 of the circuit breaker, a cam is installed on the main shaft 4 of the circuit breaker, the cam is connected with the linkage mechanism, the output gear 5 of the reducer 6 meshes with the rotor gear of the motor rotor 1, and the A spring 9 is installed in the body, and a thermal protector 3 is installed on the stator coil 2 , and the thermal protector 3 is connected in series with the stator coil 2 .

[0016] A thermal protector 3 (that is, a temperature protector) is connected in series in the circuit of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com