Miniature stepping motor

A stepping motor, miniature technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., to achieve the effect of simple installation and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

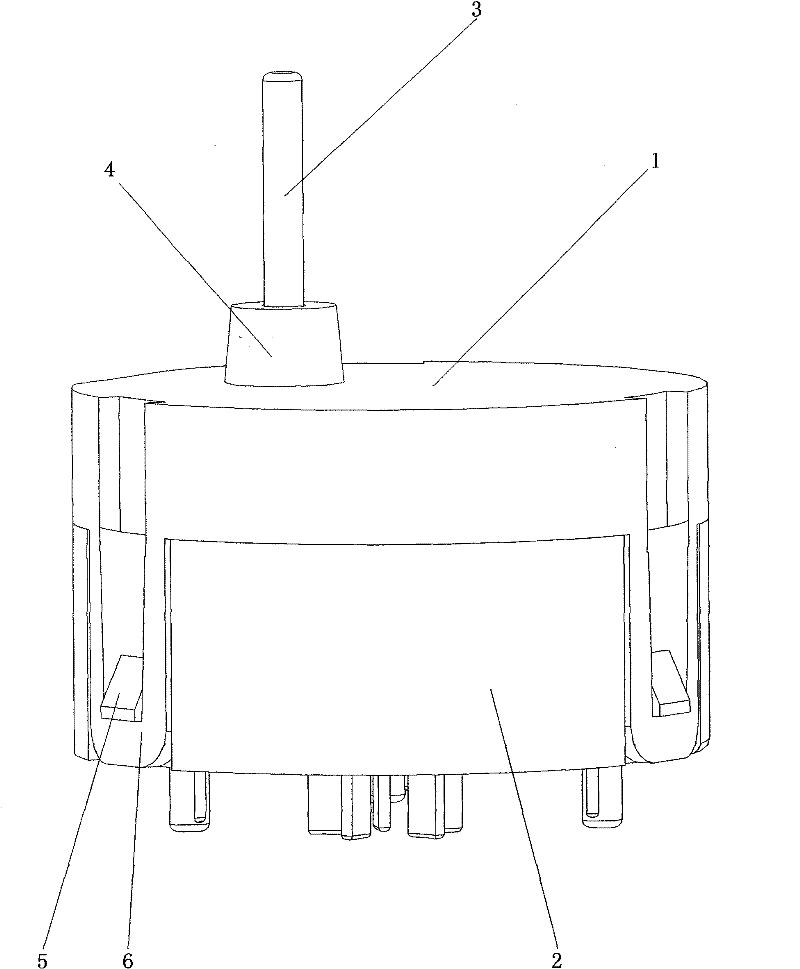

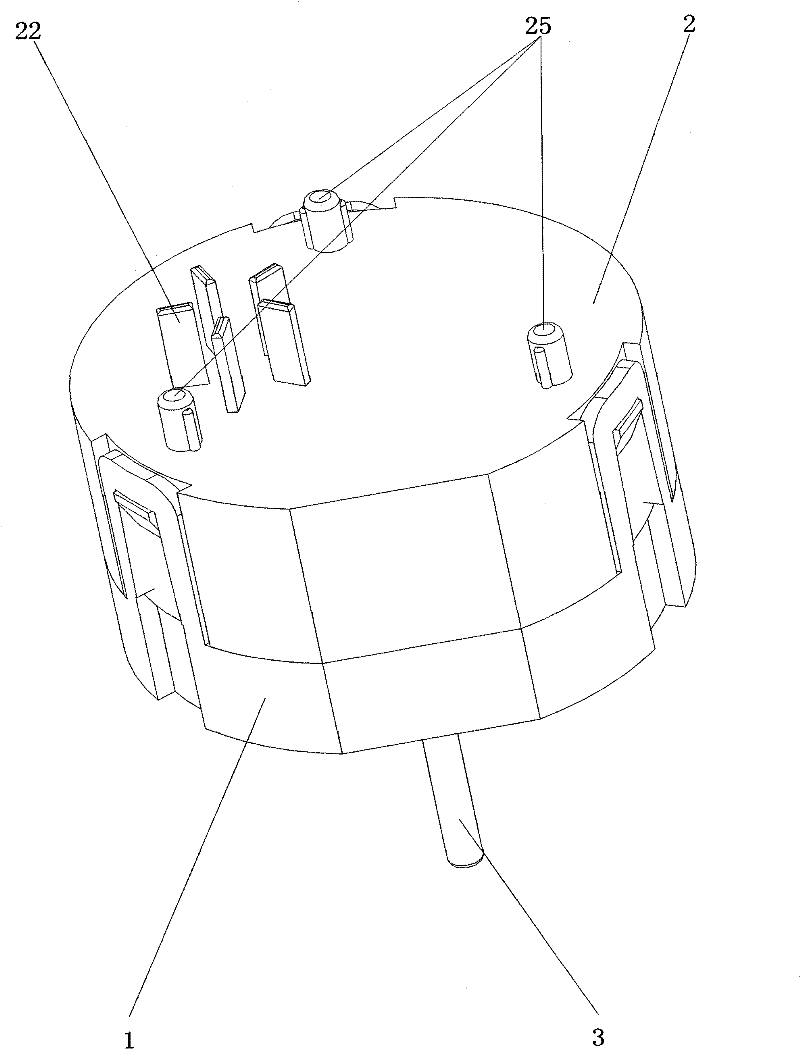

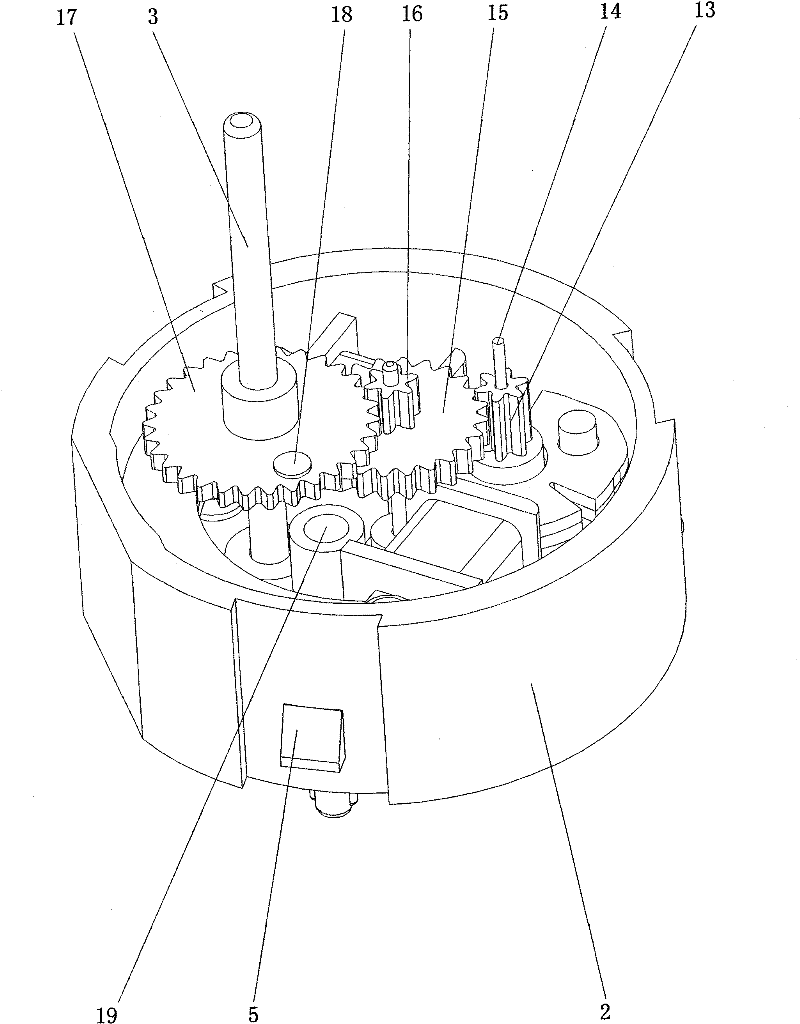

[0052] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0053]The present invention includes an upper cover 1, a lower cover 2, a motor output rotating shaft 3, an iron core body 7, a coil bobbin m8, a coil bobbin n9, a rotor body gear 13, a rotor shaft 14, a gear a15, and a gear b16 of the stepping motor. , gear c 17, light guide cylinder 19, PCB board 20, integrated infrared photoelectric tube 23 for transmitting and receiving, and dedicated chip for motor drive 24, wherein the motor output rotating shaft 3 protrudes through the center of the motor output shaft protection step 4 of the upper cover 1 . In terms of assembly, the upper cover 1 and the lower cover 2 adopt a buckle structure. There are three locking hooks 6 on the upper cover 1, and three locking posts 5 on the lower cover 2. When the upper cover 1 and the lower cover 2 are closed, , The three lock hooks 6 on the upper cover 1 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com