Nonvolatile storage element, and method for manufacturing nonvolatile storage element or nonvolatile storage device

A technology of non-volatile storage and manufacturing method, applied in the field of non-volatile storage elements, can solve the problems of large size difference, non-uniformity of characteristics, and large non-uniformity of characteristics of non-volatile storage elements, etc. , to achieve the effect of shape shift and stability and small shape shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

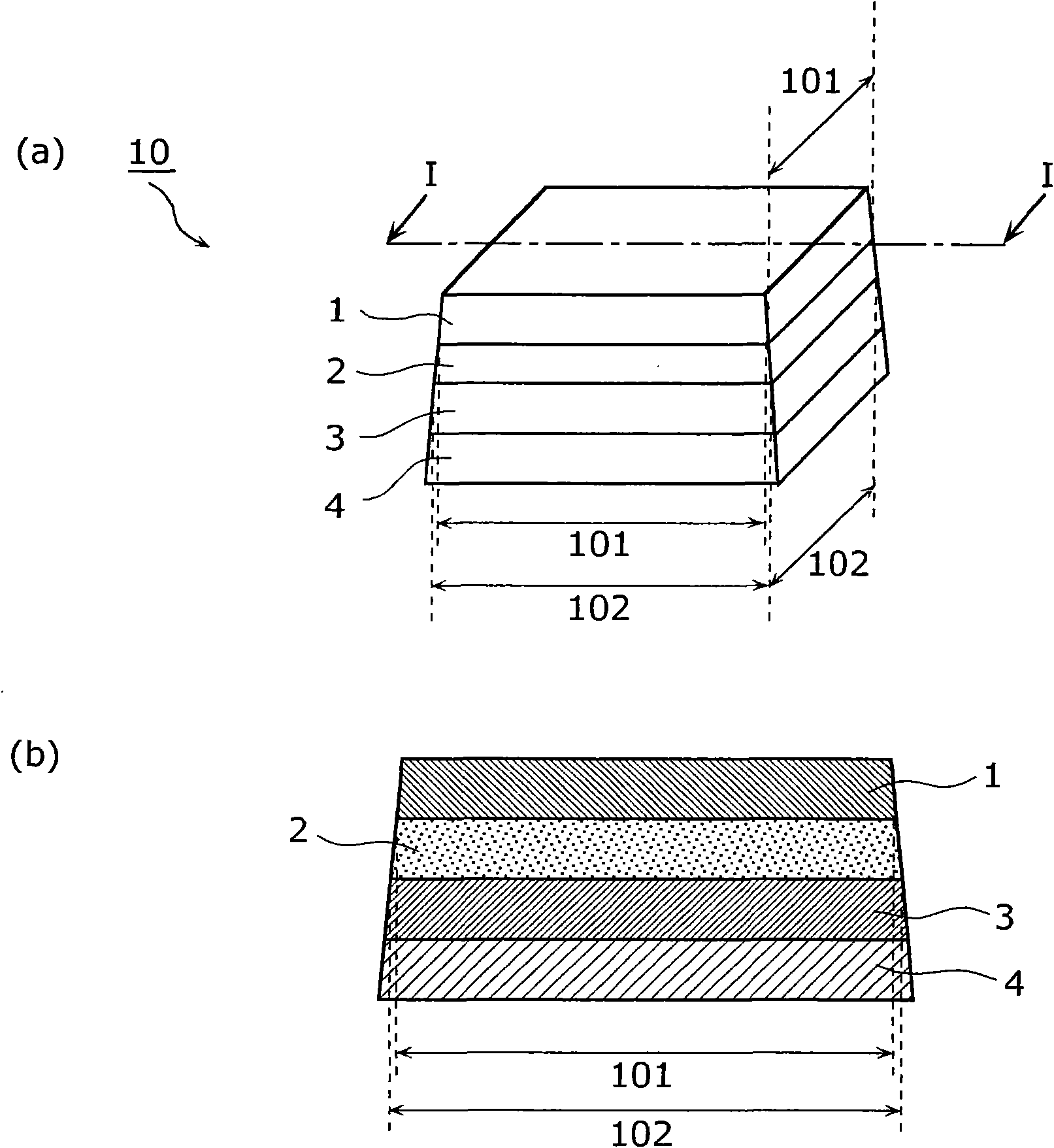

[0051] figure 1 (a) is a schematic perspective view showing the structure of the main part of the storage unit of the nonvolatile memory element 10 according to Embodiment 1 of the present invention, figure 1 (b) is shown along figure 1 (a) Cross-sectional view of the section along line I-I.

[0052] Such as figure 1 (a) and figure 1 (b) shows that the nonvolatile memory element 10 of the present invention includes the connection electrode layer 4 and the upper electrode layer 1 formed above the lower electrode layer 3 . The variable resistance layer 2 is formed between the upper electrode layer 1 and the lower electrode layer 3 .

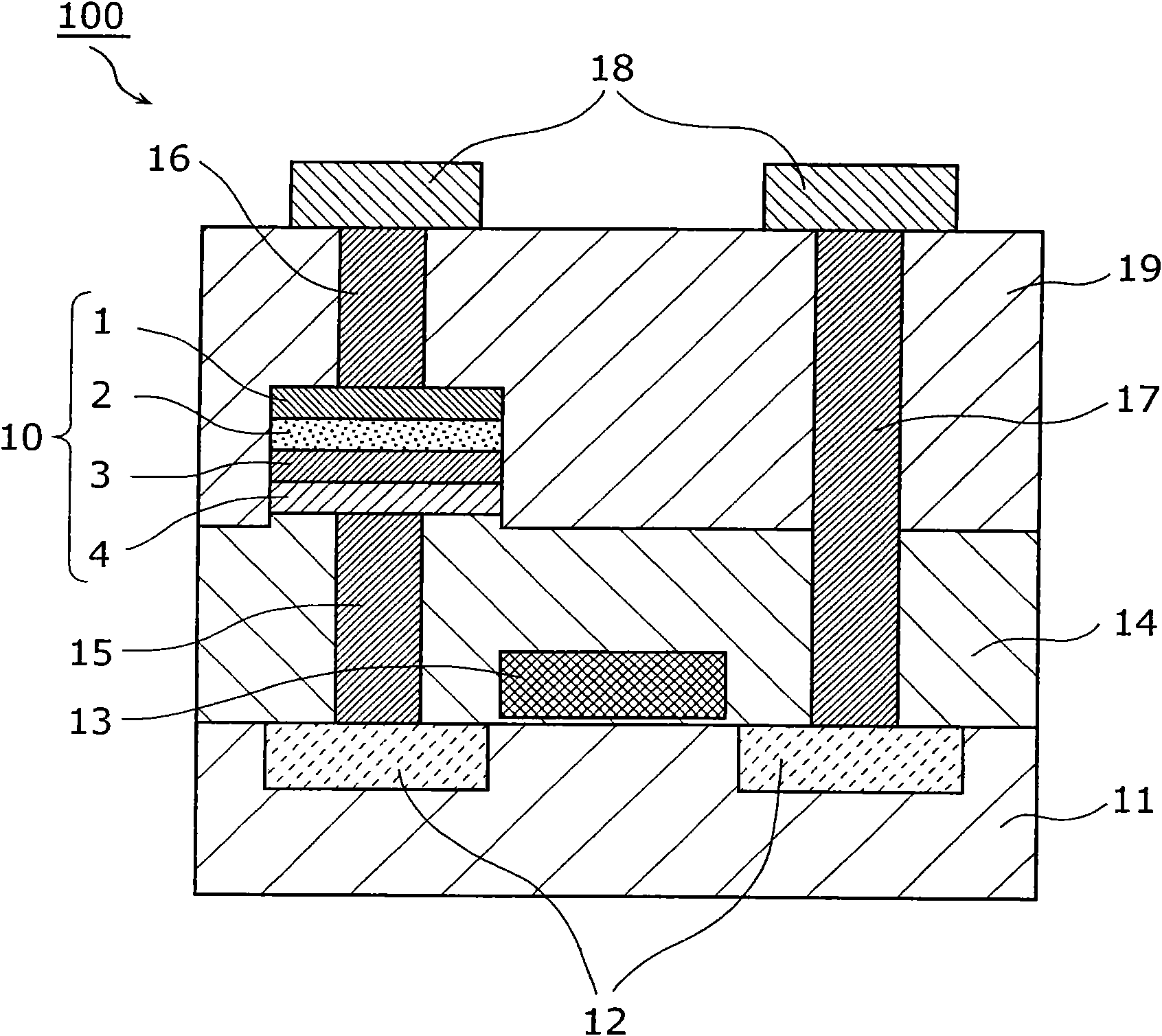

[0053] figure 2 It is a cross-sectional view showing a specific structure of a nonvolatile memory device 100 mounted with a nonvolatile memory element 10 according to Embodiment 1 of the present invention. Also, in general, many nonvolatile memory elements are formed over a substrate, but here, only one nonvolatile memory element is sho...

Embodiment 2

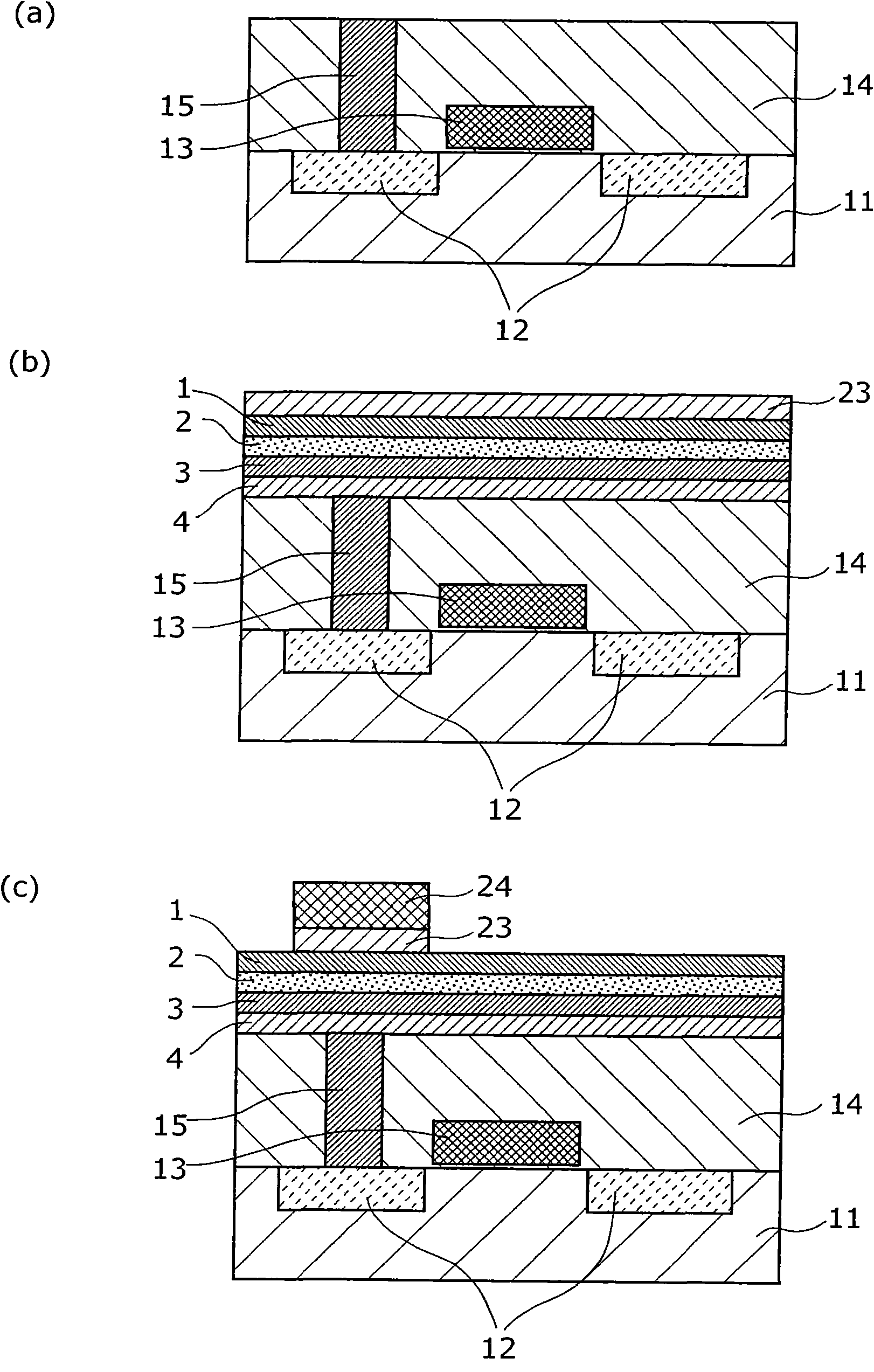

[0090] Figure 5 (a) is a schematic perspective view showing the structure of the main part of the storage unit of the nonvolatile memory element 20 according to Embodiment 2 of the present invention, Figure 5 (b) is shown along Figure 5 (a) Cross-sectional view of the II-II line cross section.

[0091] Such as Figure 5 (a) and Figure 5 (b) shows that the nonvolatile memory element 20 includes the upper electrode layer 1 formed above the connection electrode layer 4 . A variable resistance layer 2 is formed between these connection electrode layers and the upper electrode layer 1 .

[0092] and, Figure 6 It is also a cross-sectional view showing a specific structure of a nonvolatile memory device 200 mounted with a nonvolatile memory element 20 according to the second embodiment. Therefore, the upper electrode layer 1 formed above the connection electrode layer 4 is included. In the nonvolatile memory element 20 , the variable resistance layer 2 is formed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com