Tool holder

A tool holder, tool technology, used in the manufacture of tools, metal processing, accessories for tool holders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

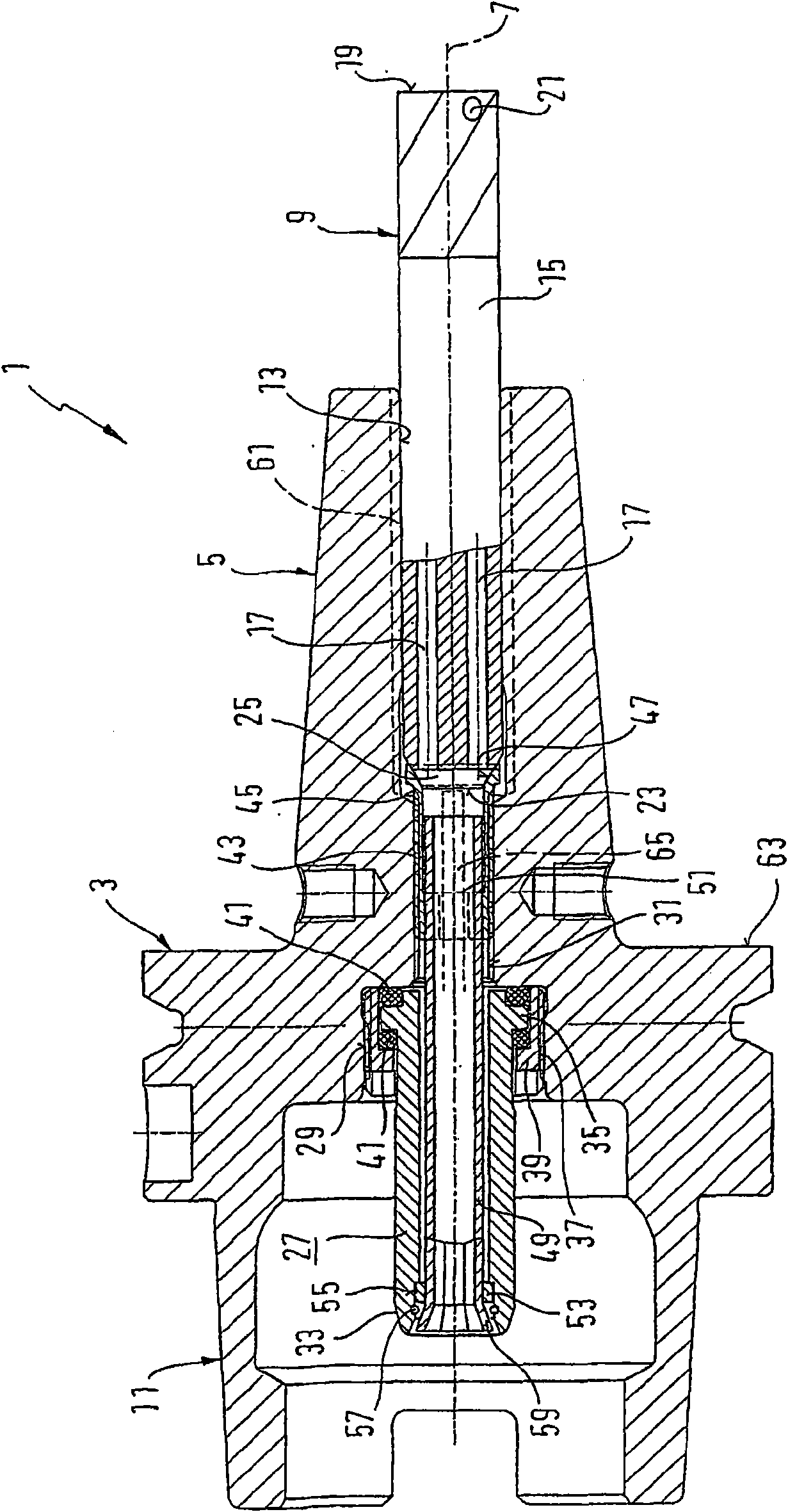

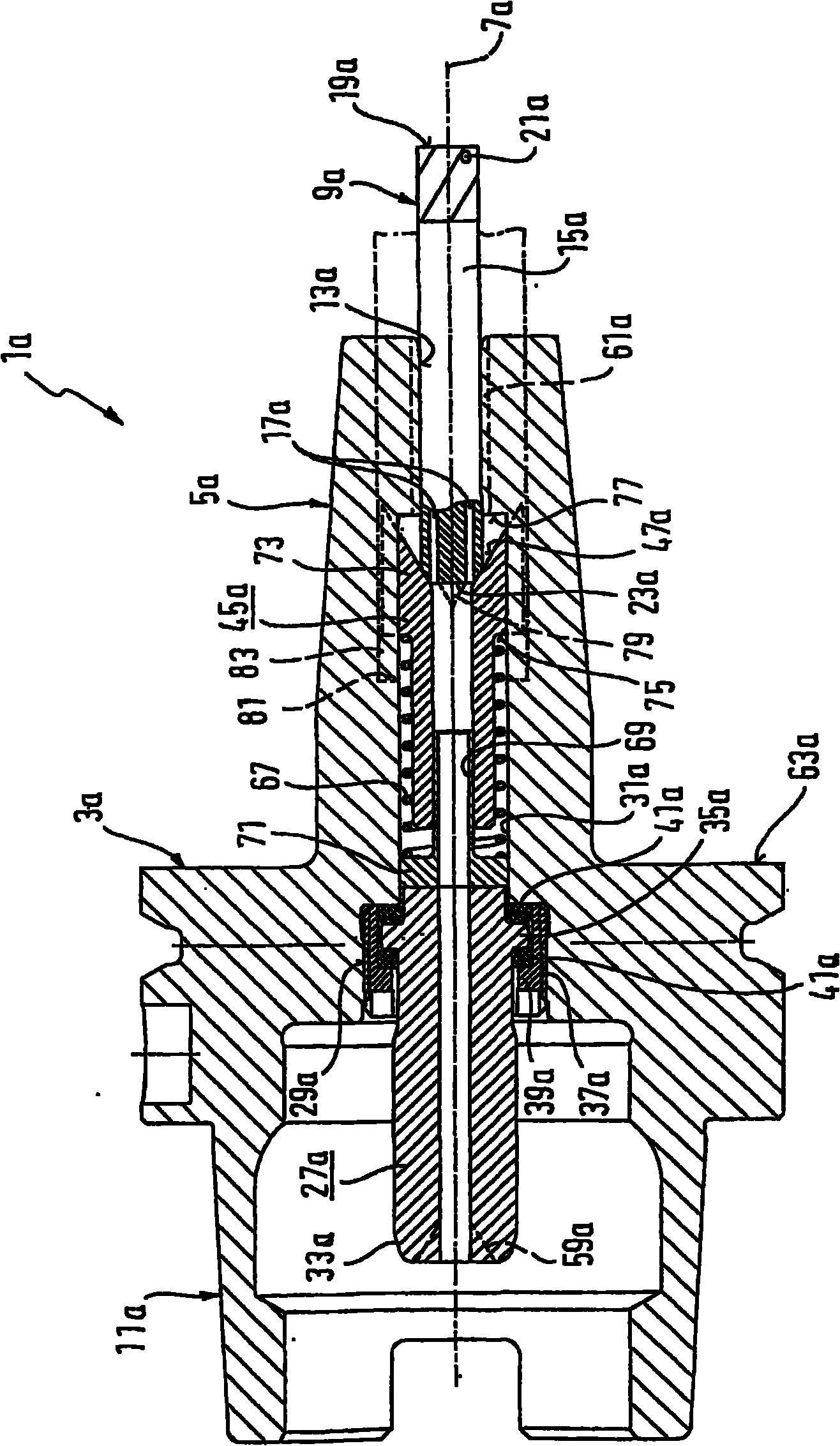

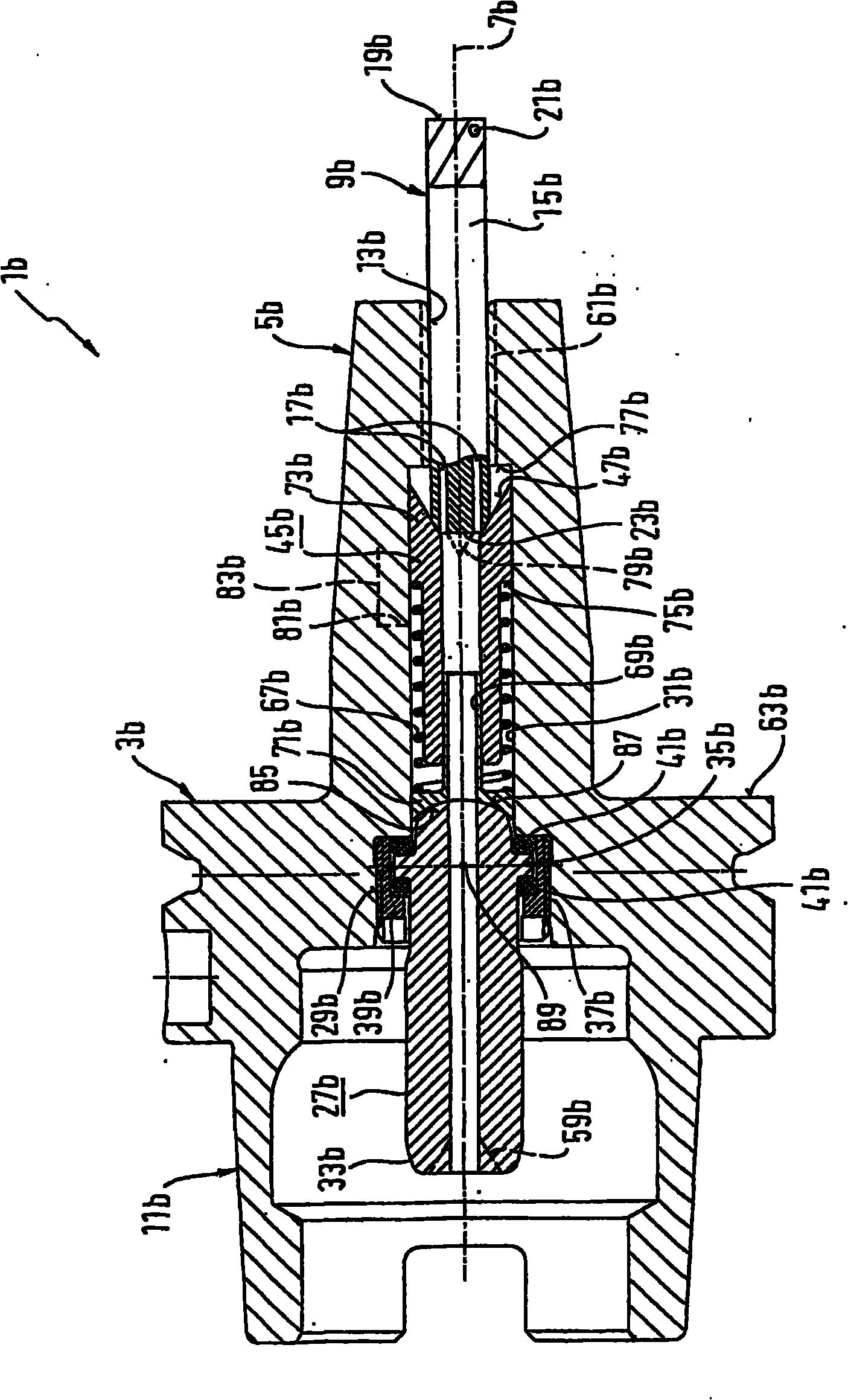

[0044] figure 1 Indicates a tool holder of the shrink chuck type, which is usually a one-piece clamp body 3 with a sleeve-shaped tool mounting section 5 at one axial end of the clamp body 3 for a drive to be rotated about an axis of rotation 7 A tool 9, such as a milling cutter or a drill bit, and at the axially opposite end there is an engaging section 11 in the form of a hollow rod adapter here, for torque-proof connection with the rotary drive shaft of the machine tool, which is not shown in detail here. join. The mounting section 5 has a mounting hole 13 concentric to the axis of rotation 7, which can be thermally expanded by means of an induction coil, in particular by induction heating, so that the tool 9 can be inserted loosely with its shank 15 into the mounting hole 13 or removed from it. After the mounting section 5 has cooled, the tool shank 15 is press-fitted into place.

[0045] A plurality of, here two, axial channels 17 parallel to the axis of rotation 7 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com