Connection protection device of flexible graphite lightning protection grounding belt

A technology of flexible graphite and protection device, which is applied to the parts, connection, coupling device and other directions of the connection device, which can solve the problem that non-metallic materials cannot be connected by conventional welding methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

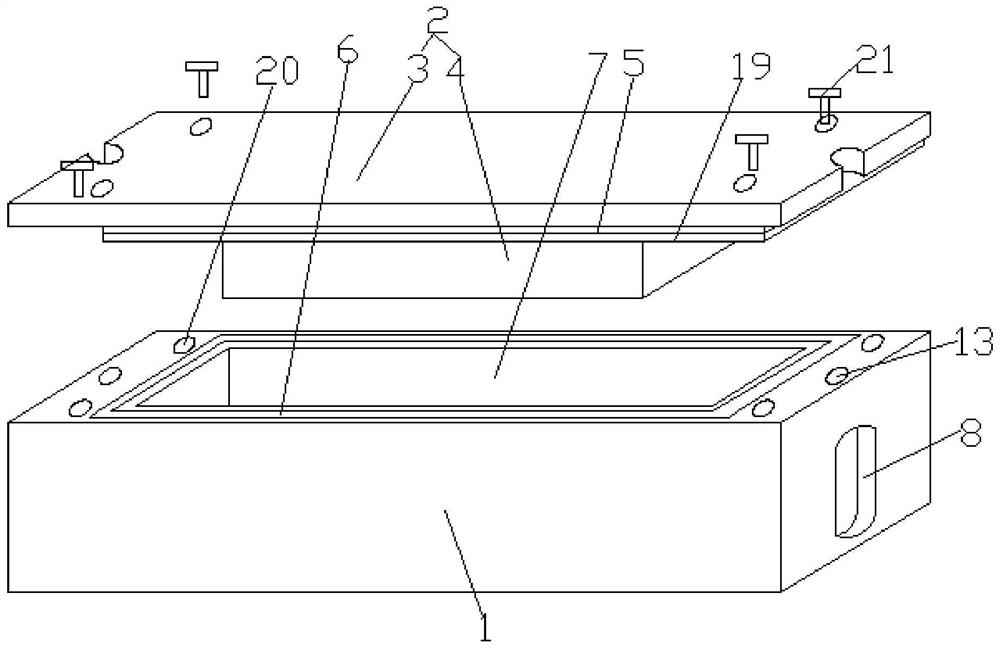

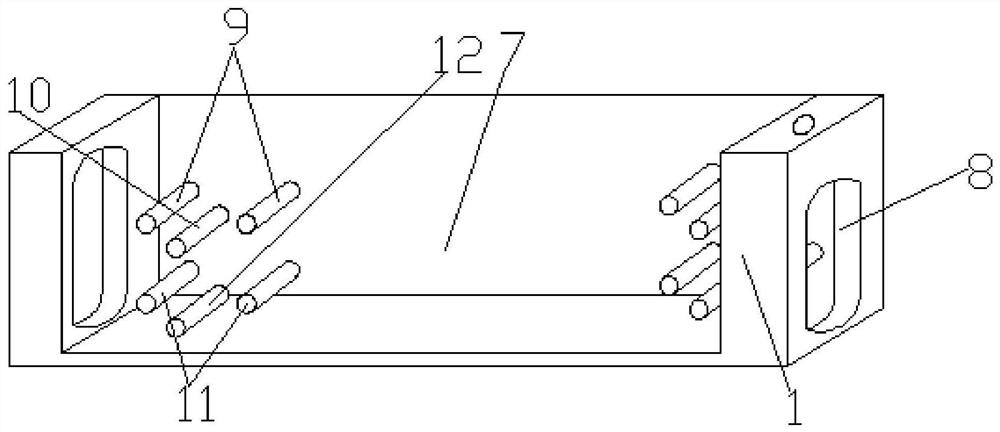

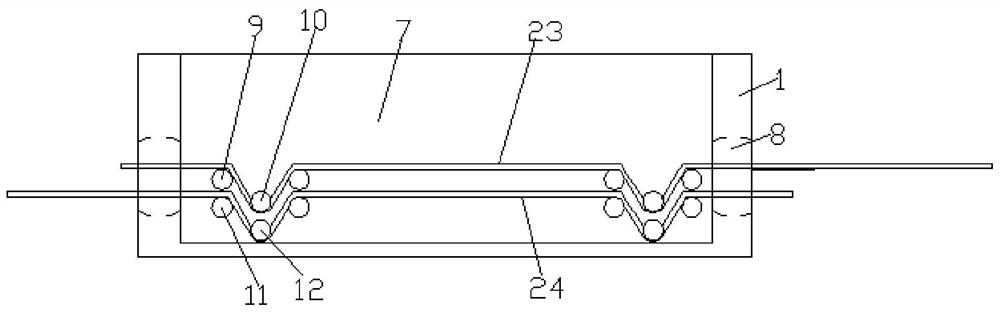

[0025] see Figure 1-4 According to an embodiment of the present invention, a connection protection device for a flexible graphite lightning protection grounding belt includes an installation box 1, a first graphite cable 23 and a second graphite cable 24, the top of the installation box 1 is provided with a cover plate 2, The cover plate 2 includes a top plate 3 and a pressure plate 4, the bottom end of the top plate 3 is fixed with the pressure plate 4, the bottom end of the top plate 3 is provided with a rectangular block 5 around the outer surface of the pressure plate 4, and the installation box 1 The top is provided with a rectangular card slot 6 matching the rectangular block 5, the inside of the installation box 1 is provided with a communication cavity 7, and the two sides of the outer wall of the installation box 1 are provided with corresponding and communicated with the The cavity 7 communicates with the through hole 8, the through hole 8 is set as oval, and the tw...

Embodiment 2

[0027] see figure 1 , for the rectangular block 5, the top of the rectangular block 5 is fixedly pasted with a sealing ring 19.

[0028] Through the above solution of the present invention, the beneficial effect is that the sealing ring 19 increases the sealing performance of the connection between the front cover plates 2 of the installation box 1 .

Embodiment 3

[0030] see figure 1 , for the installation box 1, the top of the installation box 1 and the cover plate 2 are provided with matching threaded installation holes 20, and the corresponding threaded installation holes 20 are inserted with installation screws 21.

[0031] Through the above solution of the present invention, the beneficial effect is that the installation box 1 and the cover plate 2 are fixedly connected through the threaded installation holes 20 and the installation screws 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com