Process for manufacturing large-scale long shaft by segments

A segmented manufacturing and process technology is applied in the field of manufacturing processes to achieve the effects of saving natural gas energy, saving forging costs, and improving welding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

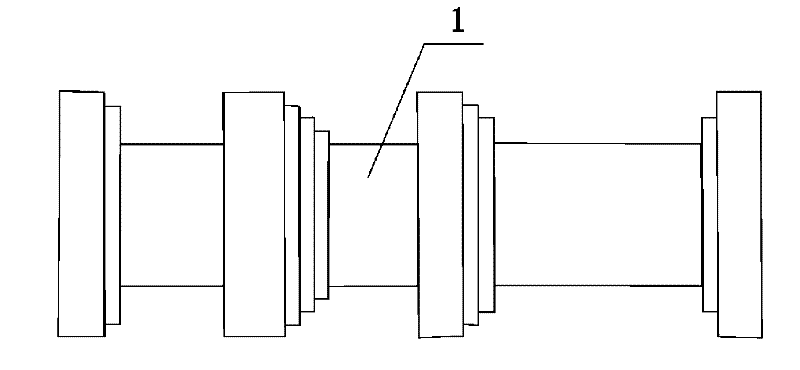

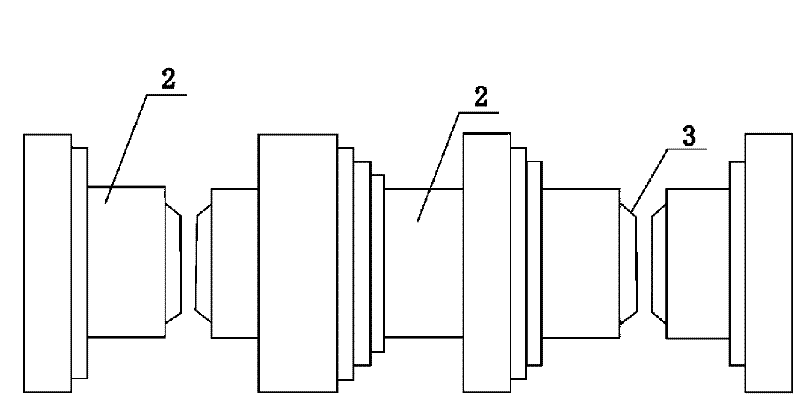

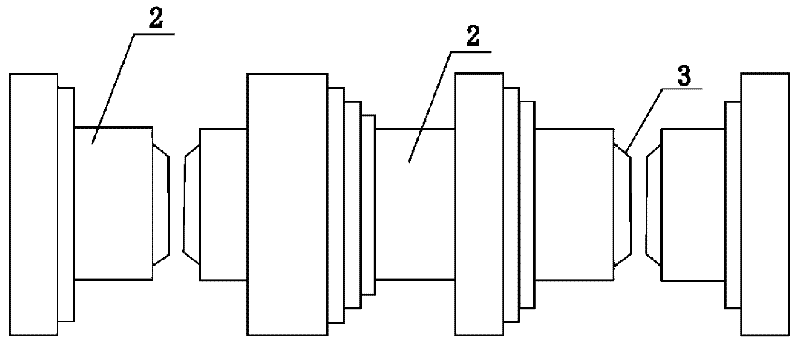

[0033] Such as figure 1 and figure 2 As shown, a large-scale long shaft manufacturing process, the whole process includes the following steps:

[0034] A. Segmented forging: the entire main shaft 1 is divided into three sections of the shaft body 2 for shaft blank forging. The length of the entire main shaft 1 is 8000mm, and the lengths of the divided three-section shaft body 2 are 2000mm, 4000mm and 2000mm respectively, and the wall thickness is 400mm;

[0035] B. Processing of welding grooves: Roughly process each section of the blank to meet the requirements of flaw detection. The inclination angle of 3 is 2 degrees;

[0036] C. Assembly welding: use narrow gap welding equipment to weld each section of the shaft body 2; the weld seam is less than 25mm, and the welding depth is 500mm during welding. The nozzle of the welding torch, the conductive plate, the conductor and the The flux funnel conveying system is correspondingly extended by 160mm, and copper-nickel alloy is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com