Underground movable reverse osmosis water treating equipment and treating process thereof for coal mine

A technology of reverse osmosis water and treatment equipment, which is used in osmosis/dialysis water/sewage treatment, mining wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

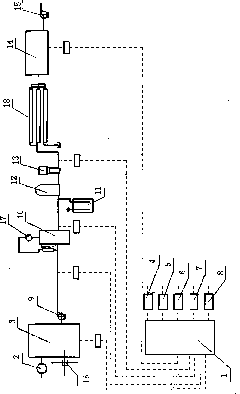

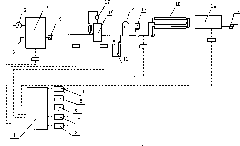

[0033] A kind of movable reverse osmosis water treatment equipment for underground coal mines of this embodiment includes a programmable controller PLC1, and the programmable controller PLC1 is connected with a raw water storage device for storing groundwater through a control circuit, and is used for pre-treatment of groundwater. The pretreatment device for processing, the pure water storage device for storing pure water, the reverse osmosis device for extracting pure water is installed between the pretreatment device and the pure water storage device; the programmable controller PLC1, the raw water storage device, the pretreatment device, reverse osmosis device 18, and pure water storage device are installed on a movable flatbed car, and the periphery of the flatbed car is equipped with a box-shaped case made of carbon steel and equipped with observation windows; The raw water tank 3 connected with the network 2 and equipped with an electromagnetic ball valve 16, the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com