Sinking or floating control method and device of multi-chamber barrel-shaped base

A barrel-shaped foundation and control method technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult sinking positioning and floating operations, increased labor and time costs, and difficulty in restoring stable operation of soft soil foundations, etc., to achieve Improve mobility and reusability, save labor costs and time costs, and facilitate sinking positioning and floating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

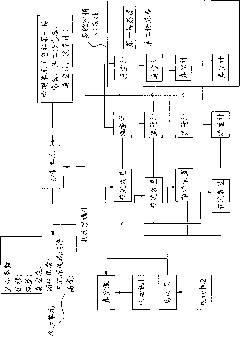

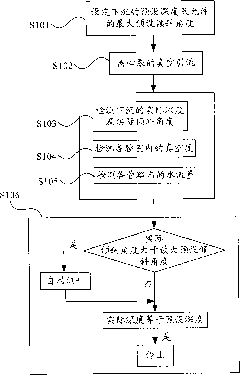

[0030] The sinking and floating control method of the multi-chamber barrel foundation according to the present invention will be described in detail below with reference to the accompanying drawings.

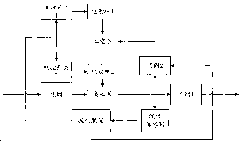

[0031] For ease of description, in conjunction with figure 1 Before describing the control principle diagram of the sinking and floating control method of the multi-chamber barrel foundation according to the present invention, first combine figure 2 Briefly describe the control principle of the vacuum drainage process of the centrifugal pump. Those skilled in the art can understand that before using the centrifugal pump to pump water for sinking control or water injection for floating control, it is necessary to perform vacuum drainage on the centrifugal pump to make it in the state of pumping water or water injection. That is, when performing the vacuum drainage operation of the centrifugal pump, the control device will close the gate valve 1 on the water outlet side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com