High pressure discharge lamp

A high-pressure discharge lamp and electrode technology, which is applied in discharge lamps, gas discharge lamps, discharge tubes, etc., can solve problems such as fusing, and achieve the effects of preventing mandrel from bending, preventing bending, and suppressing fusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

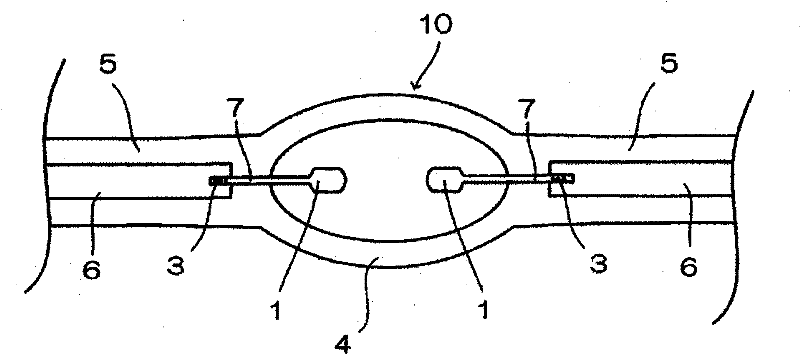

[0023] figure 1 It is a partial enlarged view showing the structure of the high-pressure discharge lamp 10 of the first embodiment.

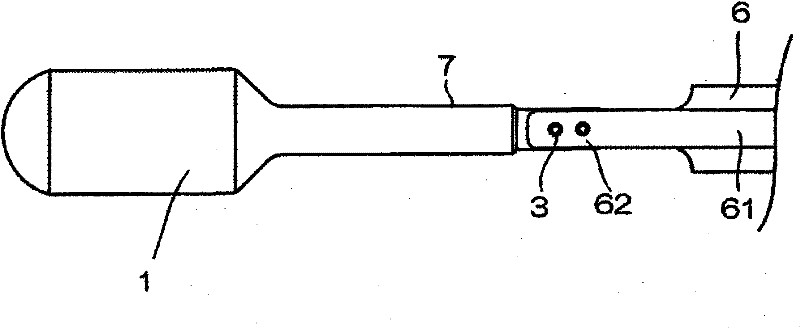

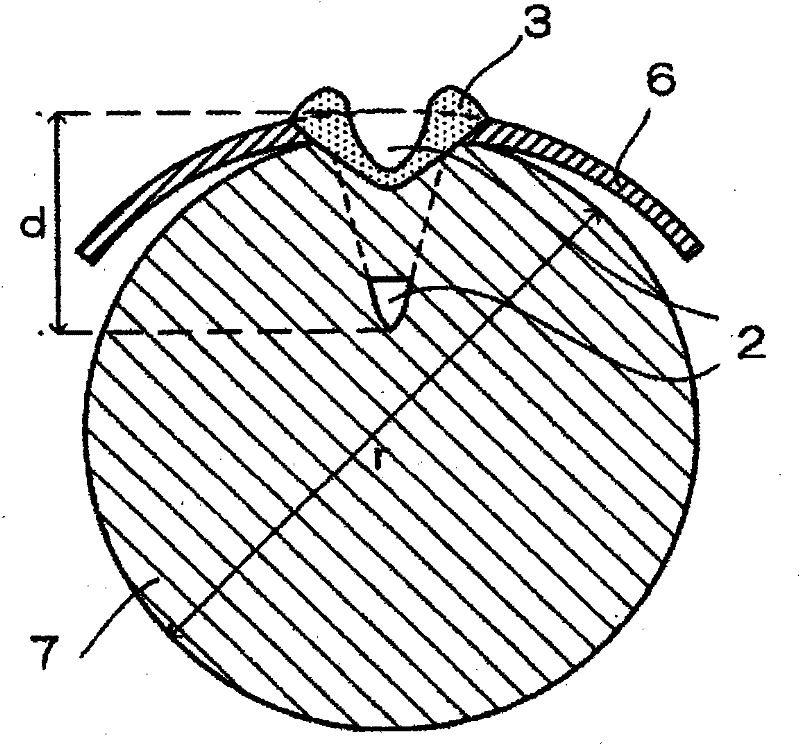

[0024] The high-pressure discharge lamp 10 has a substantially spherical light-emitting portion 4 made of quartz glass, in which an electrode 1 made of tungsten is arranged opposite. Also, a sealing portion 5 is formed so as to protrude from the end of the light emitting portion 4 , and a conductive metal foil 6 made of, for example, molybdenum is embedded in the sealing portion 5 in an airtight manner by shrink sealing. The pair of electrodes 1 is composed of a large-diameter front end and a thin-diameter mandrel 7 , and the mandrel 7 is welded to the metal foil 6 and electrically connected.

[0025] Mercury, a rare gas, and a halogen are enclosed in the light emitting unit 4 .

[0026] The amount of mercury is enclosed with 0.15mg / mm 3 Above, in order to obtain the necessary wavelength of visible light, for example, radiated light with a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com