Novel LED light source substrate, production method thereof and applied fluorescent lamp thereof

A LED light source and substrate technology, applied in the field of fluorescent lamps, can solve the problems of low light efficiency, high heat generation, poor stability, etc., and achieve the effects of high light conversion efficiency, low heat generation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with embodiment:

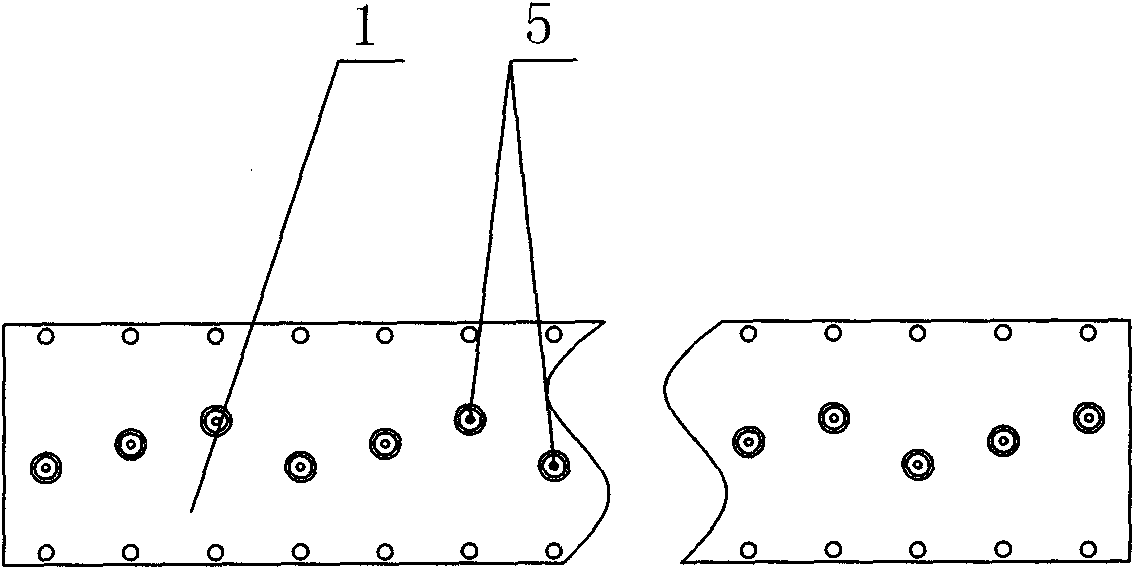

[0024] figure 1 It is the front view of the substrate 1 after forming the reflective cup of the present invention. It can be seen from the figure that a plurality of reflective cups 5 are stamped on the substrate 1 of the present invention. The substrate 1 is made of metal material aluminum or copper or magnesium (or aluminum or copper or magnesium alloy material), of course other good conductors of heat, such as new non-metallic materials are also available.

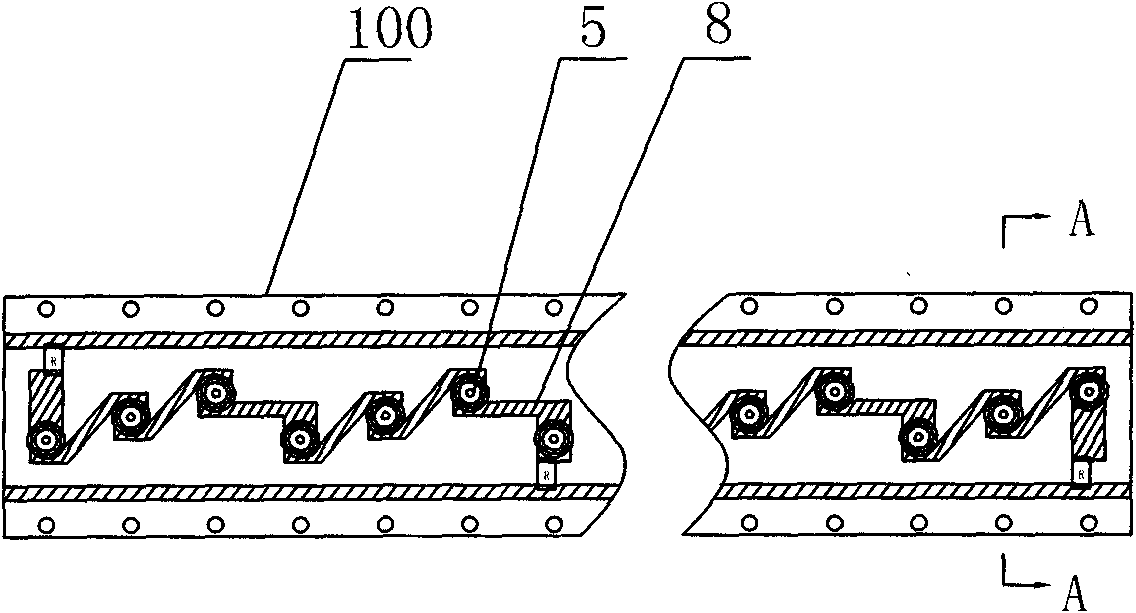

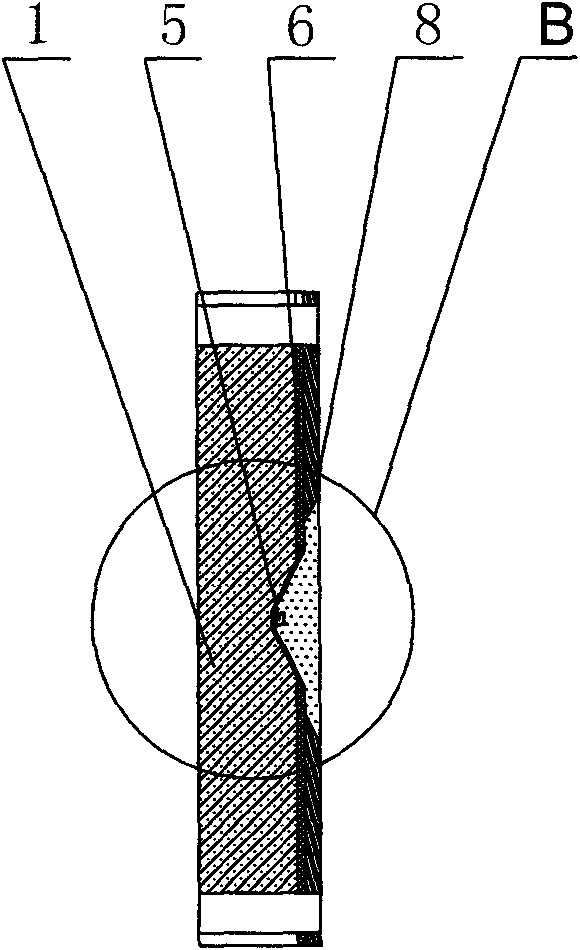

[0025] figure 2 It is the front view of the light source substrate after the present invention is manufactured, image 3 It is the A-A cross-sectional view of the light source substrate after fabrication, Figure 4 It is a partially enlarged view of the light source substrate B after fabrication. Depend on figure 2 combine image 3 , Figure 4 It can be seen that the surface of the substrate 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com