Electric film printing system and method based on DICOM

An electronic film, printing system technology, applied in the direction of transmission system, digital output to printing unit, electrical components, etc., can solve the problems of limited application scope, waste of equipment resources, waste of human resources, etc., to improve printing efficiency and reduce inspection costs , the effect of more orderly management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The DICOM-based electronic film printing system and method proposed by the present invention are described as follows in conjunction with the accompanying drawings and embodiments.

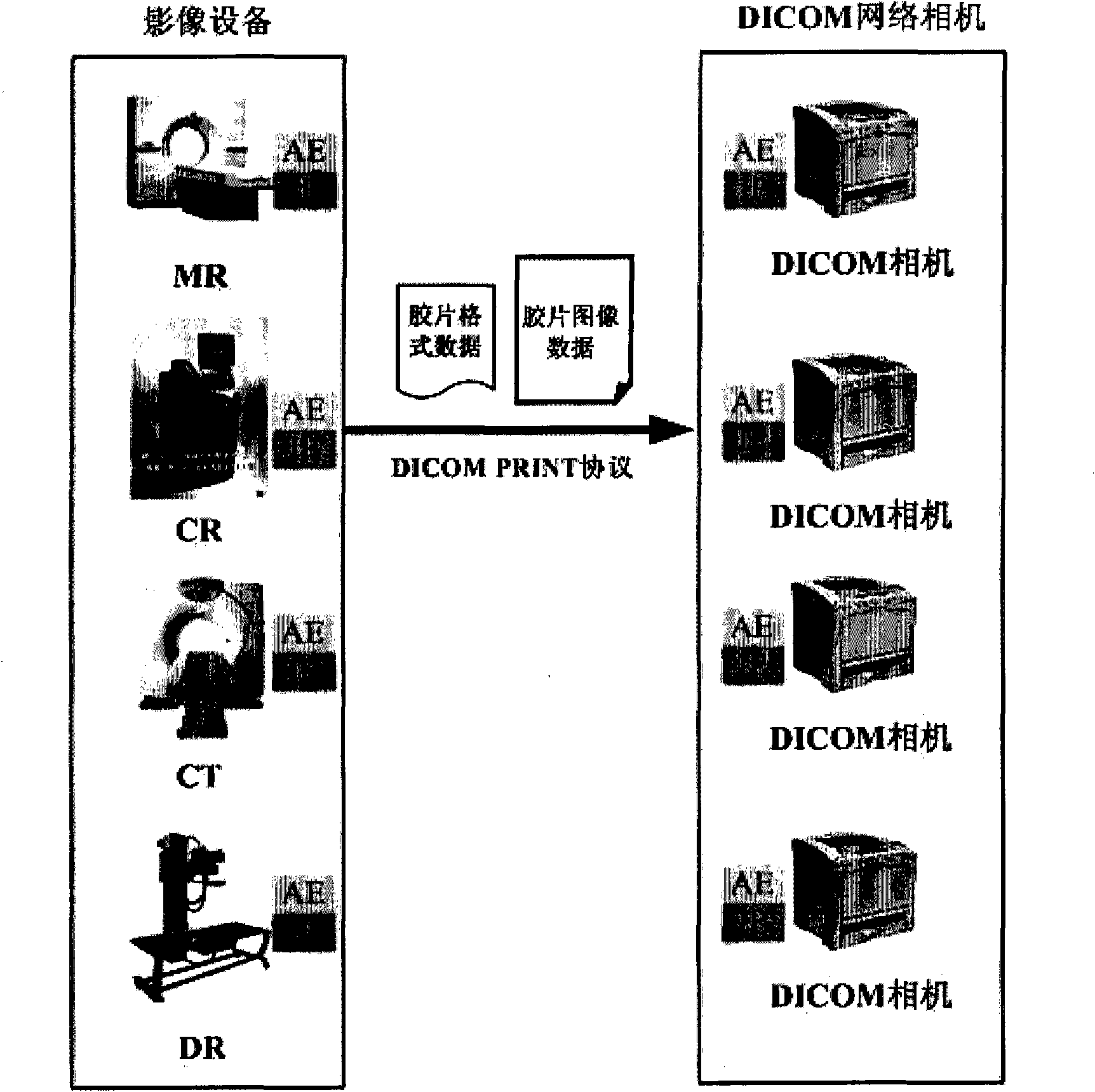

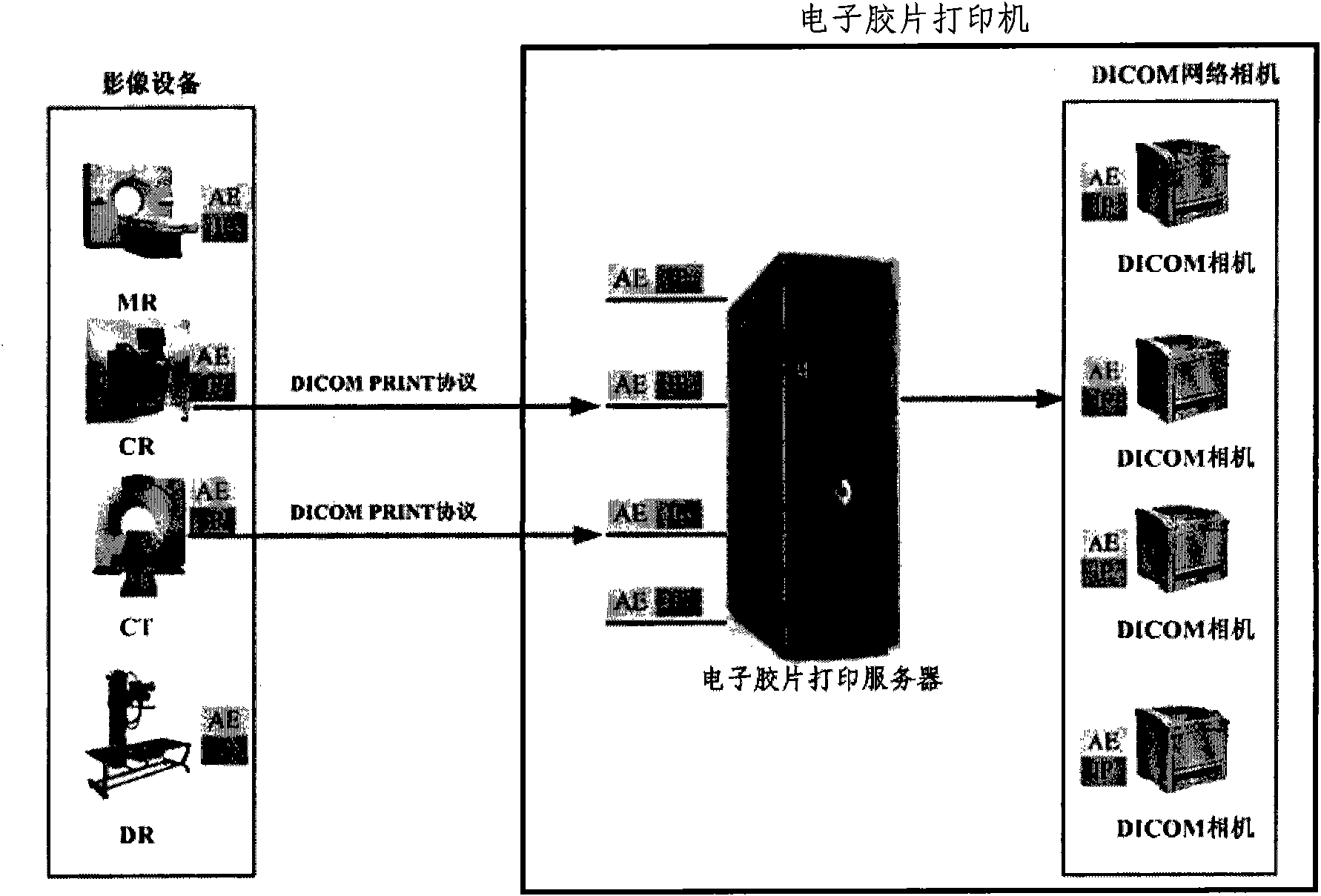

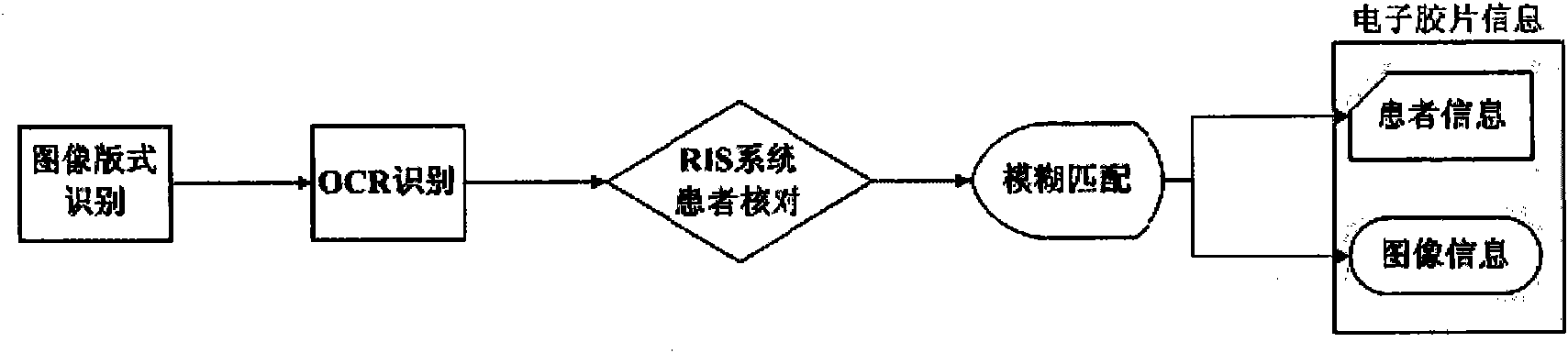

[0080] Such as figure 2 As shown, the schematic diagram of DICOM printing technology in the DICOM electronic film printing system and method of the present invention, the system includes imaging equipment and electronic film printers, wherein the imaging equipment is MR, CR and CT, etc., and these imaging equipment are used for shooting The electronic film image is sent to the electronic film printer for printing through the DICOM PRINT protocol. Wherein, the electronic film printer includes: an electronic film printing server and at least one DICOM network camera, and the electronic film printing server is respectively connected to all image devices and all DICOM network cameras. The server is used to receive the film image sent by the imaging equipment, identify the patient information ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com