Prepolymers and polymers for elastomers

An elastomer and prepolymer technology, applied in the field of polyurethane, can solve the problem of less application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

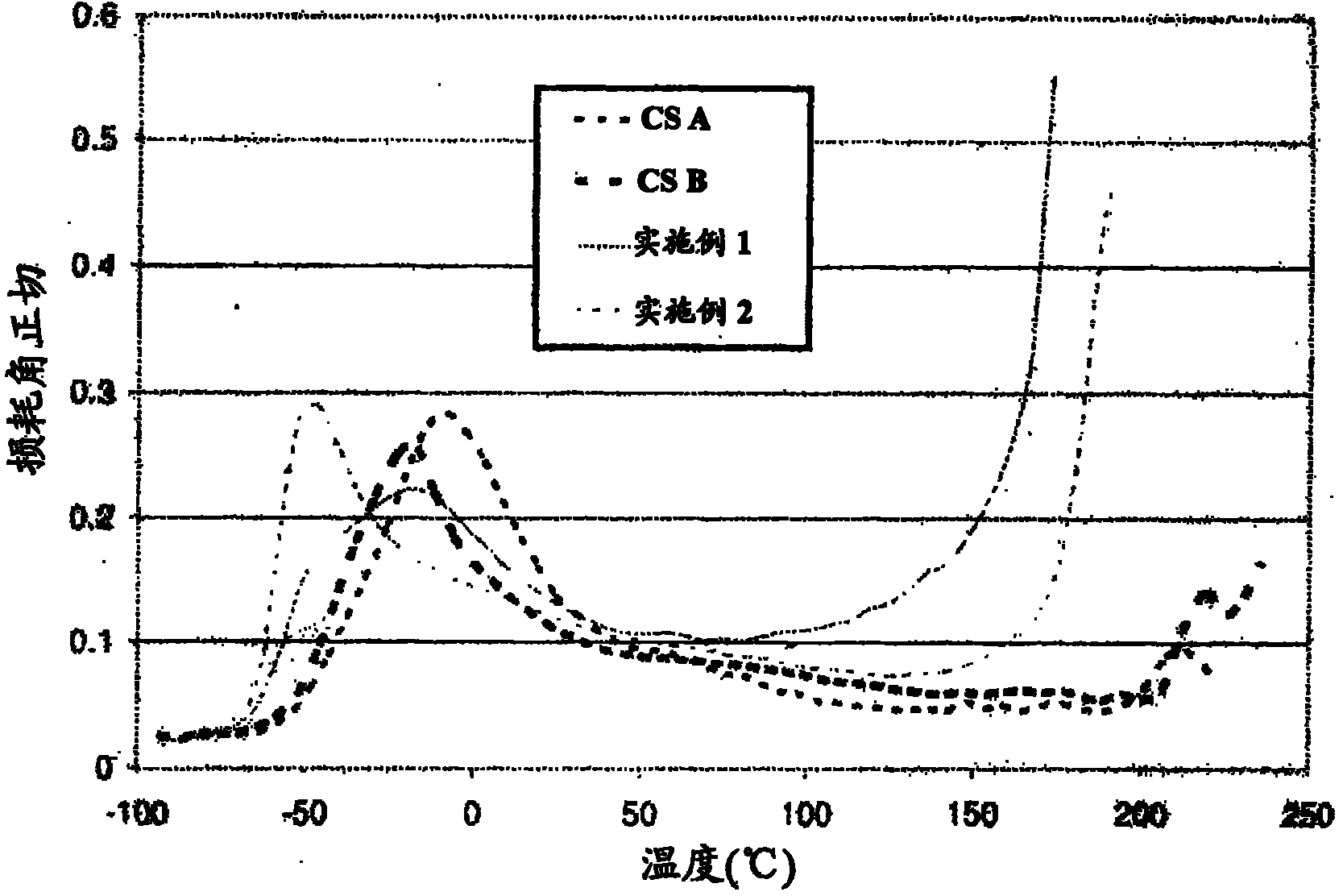

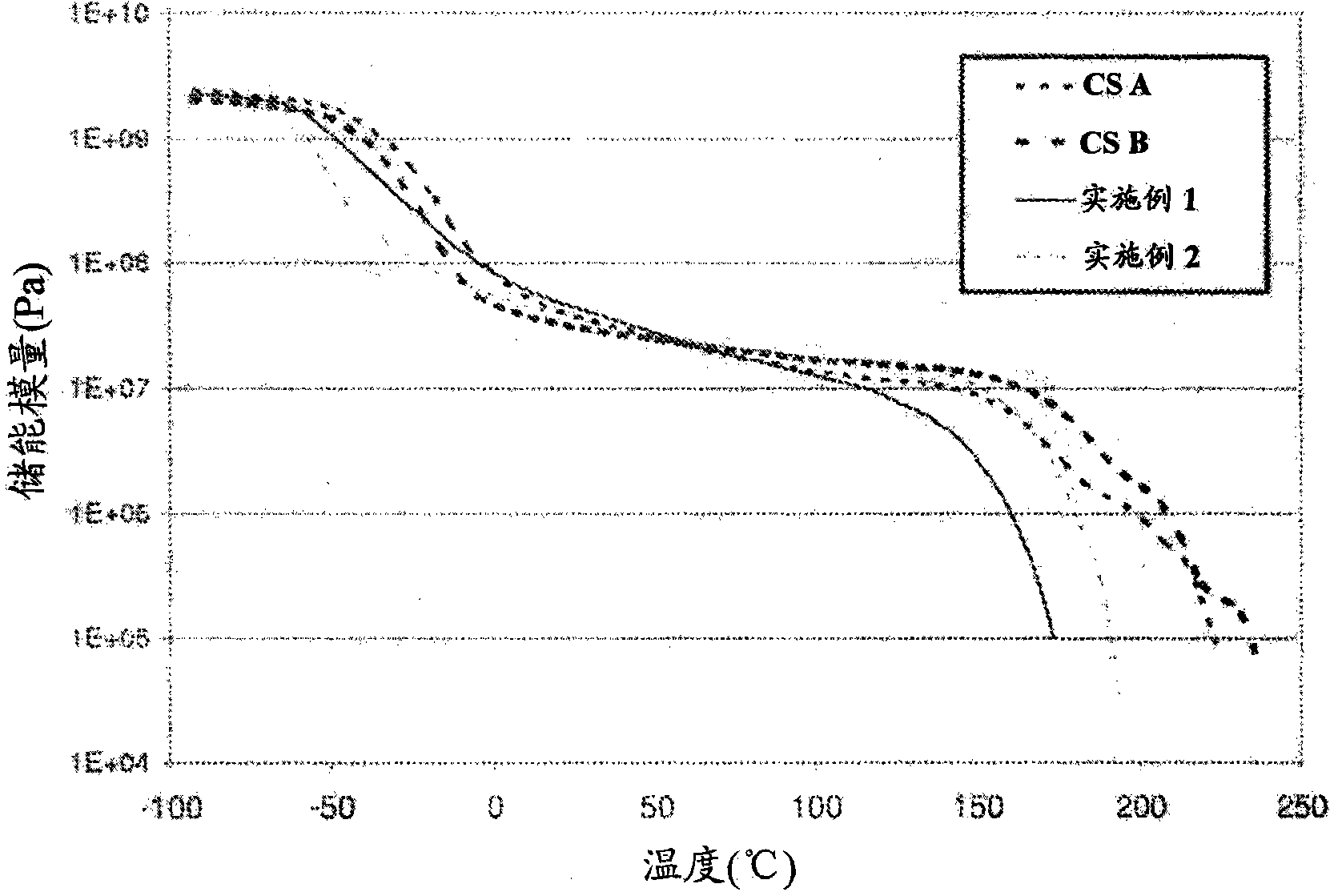

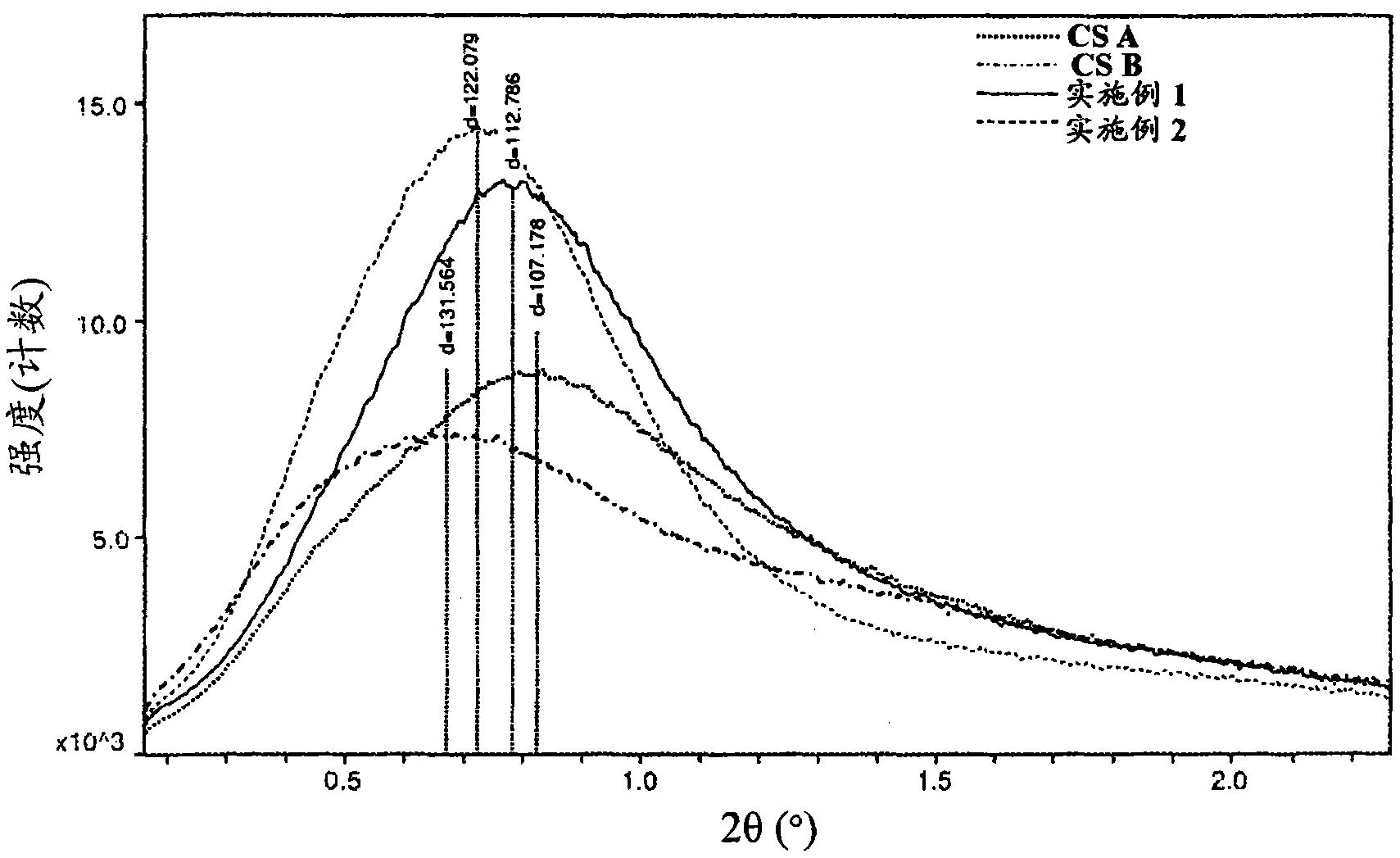

[0136] Examples 1-2 and Comparative Samples A and B

[0137] For each of Examples 1-2 and Comparative Samples A and B, the amounts and types of polyols and isocyanates shown in Table 1 were combined in a glass reactor having a volume of approximately 200 ml and stirred under a nitrogen atmosphere. The polyol was reacted with the isocyanate at a temperature of 80°C for 4 hours without catalysis to form a prepolymer. The resulting prepolymer was then characterized for free isocyanate content by the procedure of ASTM d5155 to confirm completion of the reaction. Then, in the presence of 0.01% by weight of the total reaction mixture dibutyltin dilaurate catalyst (commercially available as Dabco T-12 from Air Products), the prepolymer was mixed with 1,4-butylene in the amount shown in Table 1. Diols (BDO) were reacted by combining them in a tri-pour container with a volume of 200 ml and stirring manually using a spatula at a temperature of 50° C. for a period of 10 minutes to initi...

Embodiment 3

[0149] The procedure of Example 3 was used to prepare the foam coated blanket samples of Comparative Sample C, except that Comparative Sample C was used in which the polyol blend consisted of 4691 g POLY-1, 1768 g NOPO-E and 615 g diethylene glycol Preparation of formulations made from diols.

[0150] Table 3 shows the ASTM test results for the films of Comparative Sample C and Example 3.

[0151] Column 2 of this table lists the ASTM test number for each test except viscosity using a Brookfield viscometer using a #7 spindle at set temperature and speed in revolutions per minute (RPM) (in Table 3). , measured at 20 RPM at 10°C); cure time is recorded as the time from placing the sample in an oven at 129°C until its surface reaches 110°C; gel time is recorded as the time from the addition of the catalyst to the time the material was measured using a #7 spindle The time when the viscosity is at least 100,000 cp; and the tensile strength is measured according to the procedure of...

Embodiment 4-9

[0157] Examples 4-9 and comparative samples D-G

[0158] For each of Examples 4-9 and Comparative Samples D-G, the amounts and types of polyols and isocyanates in Table 4 were combined in a glass reactor with a volume of approximately 140 ml and stirred under a nitrogen blanket. Benzoyl chloride droplets were added to make the reaction medium slightly acidic. The polyol and isocyanate were reacted at a temperature of 80° C. for 4 hours without a catalyst to form a prepolymer. The resulting prepolymer was then characterized for free isocyanate content according to the procedure of ASTM d5155 to confirm completion of the reaction. The prepolymer was then reacted with the amounts and types of chain extenders shown in Table 4 at a stoichiometric ratio of 1.05:1. The reaction mixture was then poured into a press with dimensions 16 x 16 cm where it was pressed at 140 MPa, 80° C. for 1 hour to form a sheet. The sheet was then removed from the heated press and placed in an oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com