Flue gas purification method and device of electrolytic aluminum smelting furnace and heat preserving furnace

A technology for flue gas purification and smelting furnaces, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve the problems of enlarged fan equipment, increased equipment cost, and high cost of use, and achieves reduced production and operation costs. Automation High degree of control and thorough purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

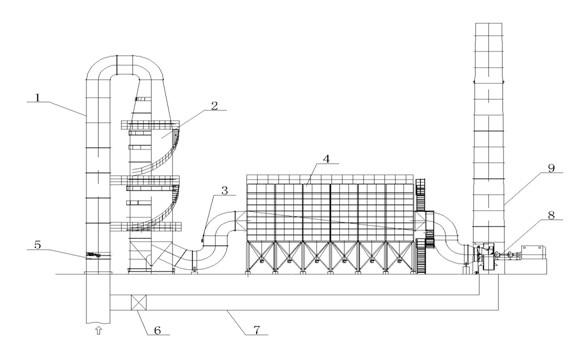

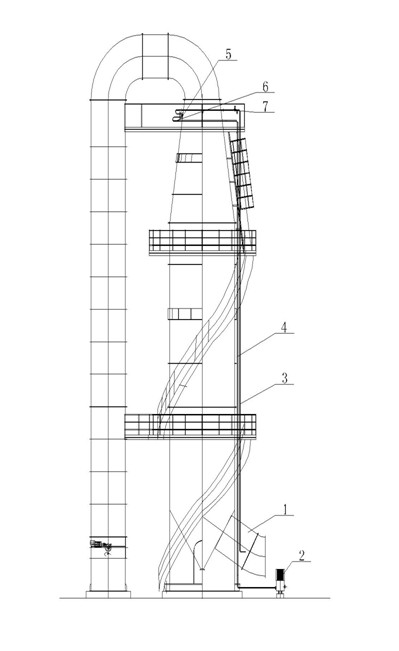

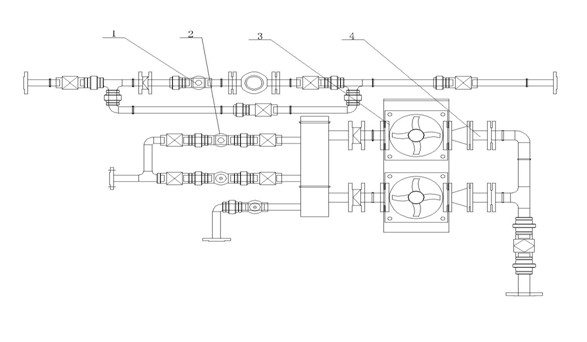

[0017] Such as figure 1 As shown, a method for purifying flue gas from an electrolytic aluminum smelting furnace and a holding furnace, under normal circumstances, due to the suction of the induced draft fan 8, the flue gas from the smelting furnace and the holding furnace enters through the flue valve 5 and the flue gas pipe 1 The cooling tower 2 is used for cooling, the flue gas enters the tower from the top of the cooling tower, the temperature sensors at the inlet and outlet of the cooling tower measure the temperature, and the flow of water out of the high-pressure nozzle on the spray valve is controlled by PLC, the compressed air enters the high-pressure nozzle, and the cooling The water droplets at the outlet of the bottom of the tower are all vaporized and evaporated, the flue gas is dried after cooling down, and the cooled flue gas enters the bag filter 4 for separation and purification, and the purified flue gas is emptied by the chimney 9 through the induced draft fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com