Method for assessing reliability of technology for large numerical control machine

A CNC machine tool, reliability technology, applied in metal processing, manufacturing tools, metal processing equipment and other directions, can solve the problems of not considering the process reliability change of the process system, the reduction of machining accuracy, wear, vibration, thermal deformation, etc., to solve The problem of acquiring dynamic characteristics of machine tools, the effect of improving efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

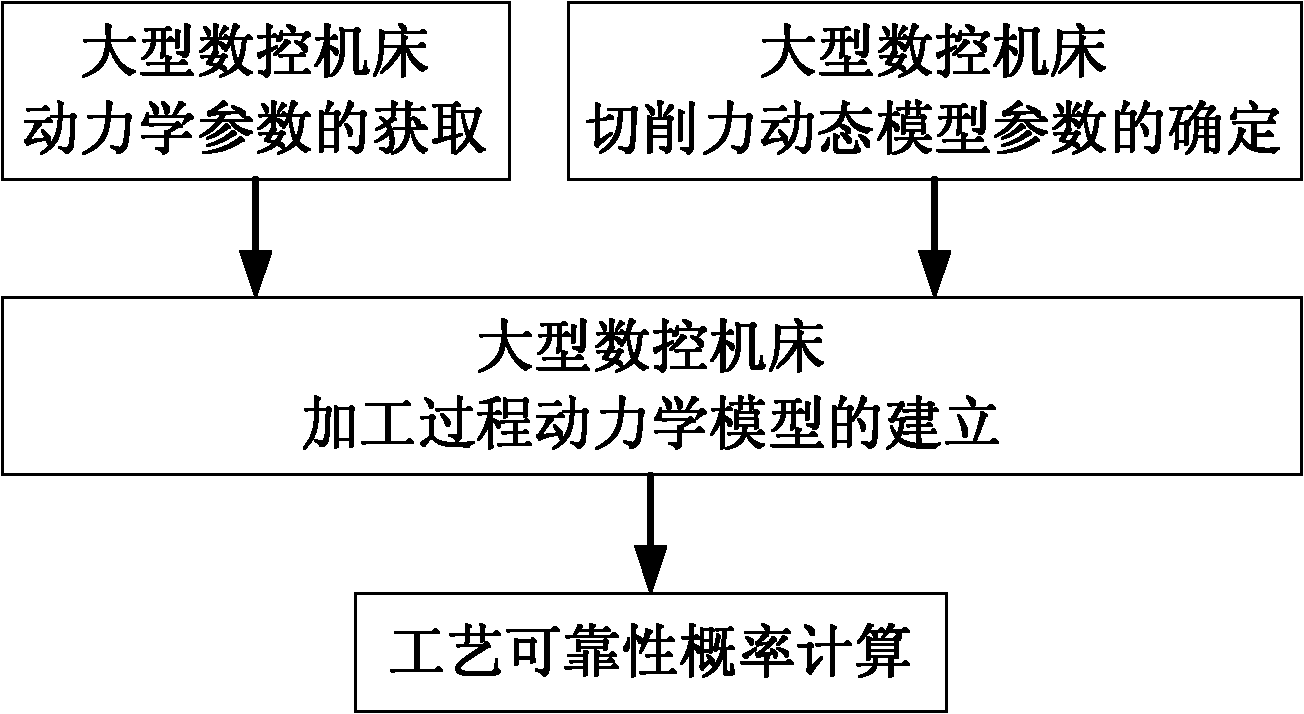

[0026] Concrete implementation steps of the present invention are as follows (with reference to figure 1 ):

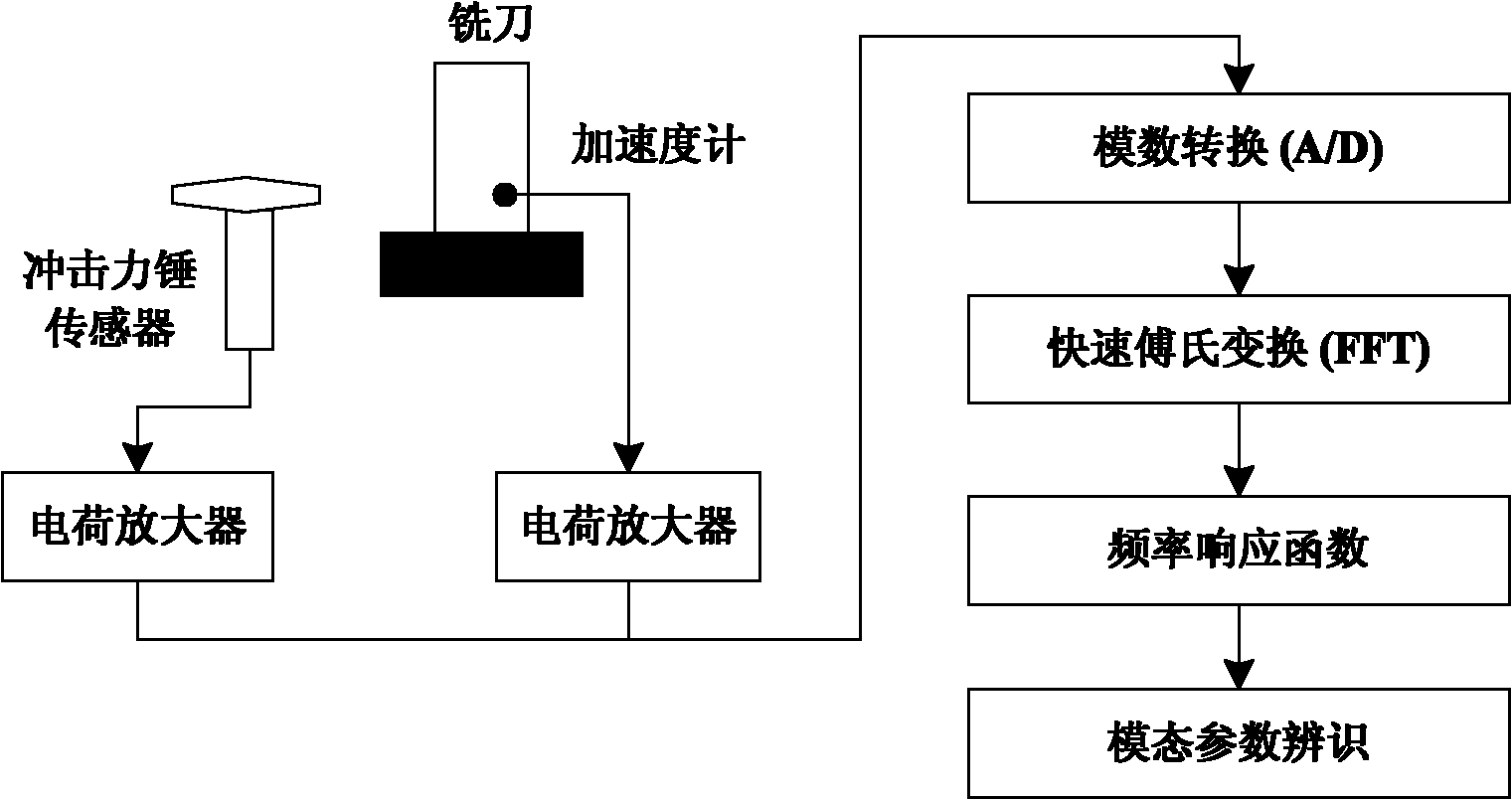

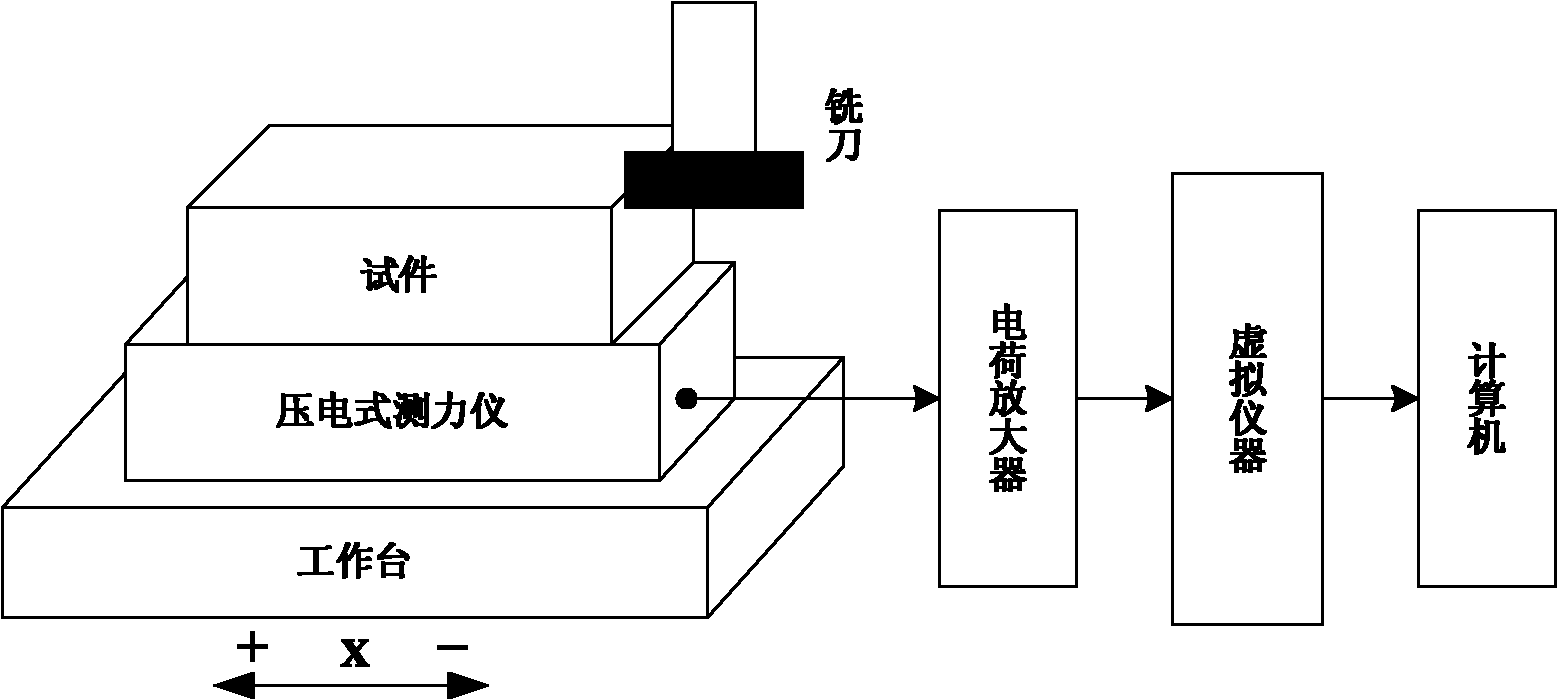

[0027] (1) Identification of kinetic parameters. Since the process reliability of the CNC machine tool is affected by the mechanical structure of the machine tool and the processing technology system, the present invention first needs to identify the dynamic parameters of the machine tool mechanical structure, that is, the natural frequency ω n , the damping ratio ξ and the stiffness coefficient k. The frequency response function method is used to identify the dynamic parameters of the equipment, that is, according to the relationship curve between the excitation frequency and the response amplitude, the parameter identification method is used to infer the dynamic parameters of the machine tool. The CNC machine tool is simplified as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com