Color antistatic PVC (Polyvinyl Chloride) conveyor belt for electronic industry and manufacture method

A technology for the electronics industry and a manufacturing method, which is applied in the field of color antistatic PVC conveyor belts for the electronics industry and the manufacturing field, can solve problems such as the decrease in tensile strength, impact strength, elongation, single color, and decrease in PVC resistivity, and achieve strong Market competitiveness, low price of finished products, and the effect of avoiding static electricity accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

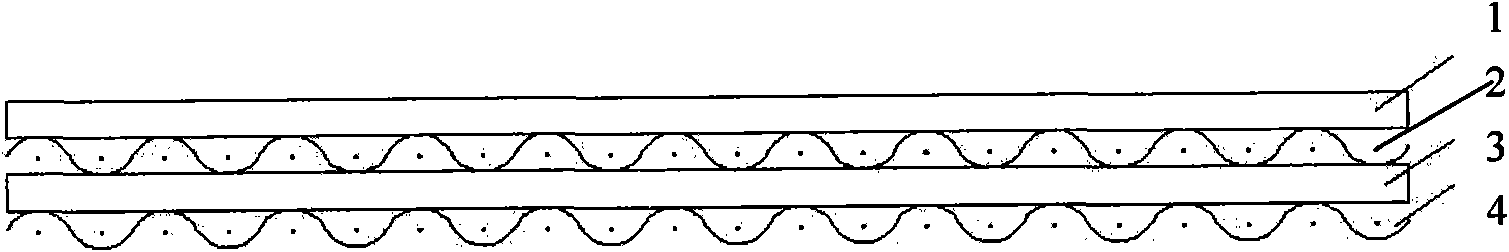

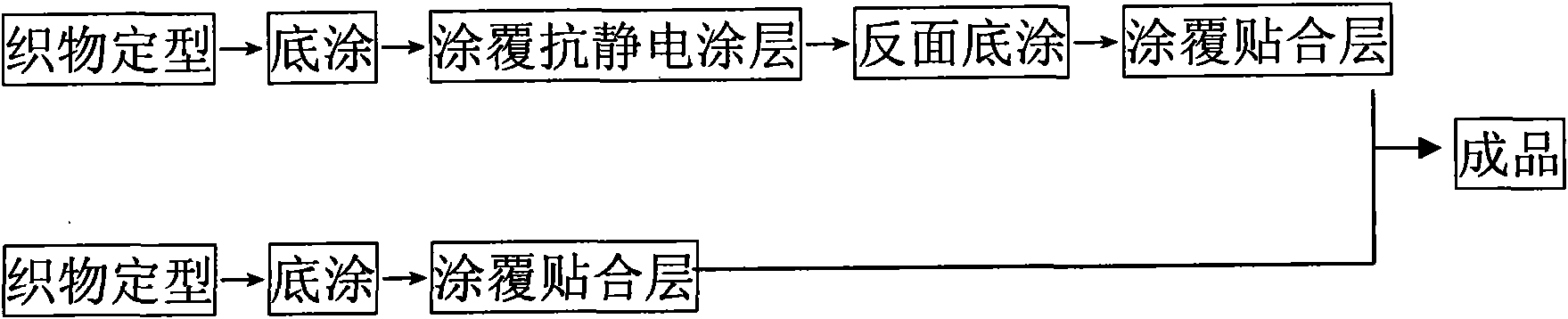

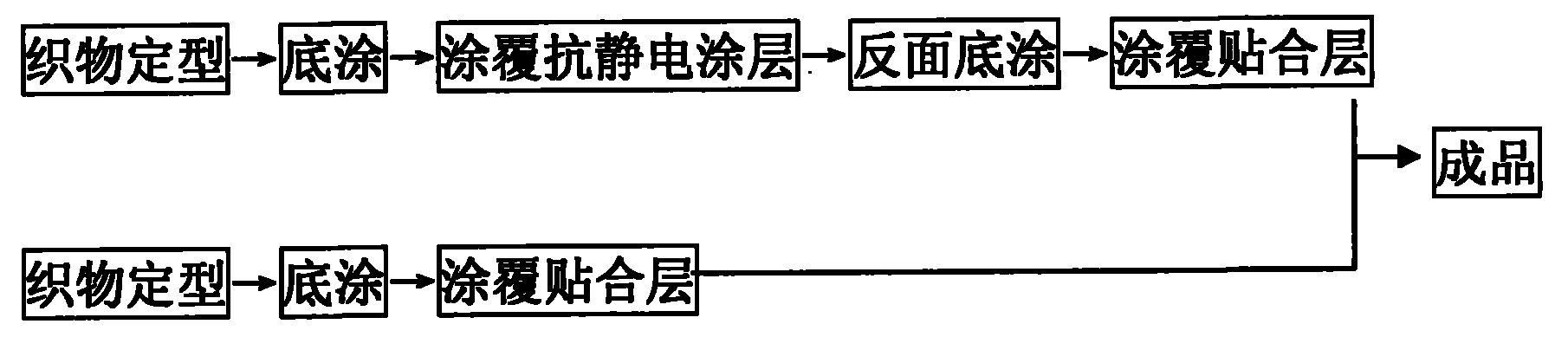

[0025] See figure 1 and figure 2 , wherein, the basic formula of the antistatic coating used is composed of: PVC paste resin, 100; plasticizer, 50-70; stabilizer; 2-3; antistatic agent HB3, 10-15; color paste, appropriate amount.

[0026] Component

1

2

3

4

5

PVC paste resin

100

100

100

100

100

plasticizer

50

55

60

65

70

stabilizer

2-3

2-3

2-3

2-3

2-3

Antistatic agent HB3

15

13

12

11

10

[0027] Component

1

2

3

4

5

color paste

Appropriate amount

Appropriate amount

Appropriate amount

Appropriate amount

Appropriate amount

[0028] Among them: the plasticizer is dioctyl phthalate (DOP)

[0029] The stabilizer is calcium zinc stabilizer (CZ)

[0030] Prepare PVC paste according to the above antistatic formula, adopt coating process, and use infr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap