Method for molding vertical wall of deep foundation pit

A forming method and deep foundation pit technology, which can be applied in excavation, foundation structure engineering, blasting, etc., can solve the problems that the foundation of the factory cannot be constructed, affect the promotion of construction technology, and the structure of the foundation pit is unstable, so as to achieve good comprehensive benefits and difficult construction Small size, the effect of improving the safety of protection

Inactive Publication Date: 2010-08-18

CHONGQING IRON & STEEL (GRP) CO LTD

View PDF6 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method of mechanical grading and large excavation is mainly suitable for shallow soft soil foundation pits, and a large amount of rocks will be encountered in the excavation of ultra-deep foundation pits, so its construction is very difficult; During the excavation, it was necessary to divide into multiple steps and form a very long horse path, resulting in the excavation surface and excavation line reaching tens of meters, which had a serious impact on the construction of other nearby projects, making it impossible to construct the foundation of the factory building. At the same time, After pouring concrete on the pool wall, earthwork backfilling will also generate a very large lateral pressure on the pool wall structure. This additional load will cause the foundation pit structure to be unstable, and there are certain safety hazards

Not only that, considering the progress of the project and the analysis of the project cost, the method of grading and excavation not only takes a long time and has a large amount of work, but also costs a lot in excavation, transportation and backfilling. The project period is long and economical. The unfavorable factors of high cost also directly affect the promotion of construction technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

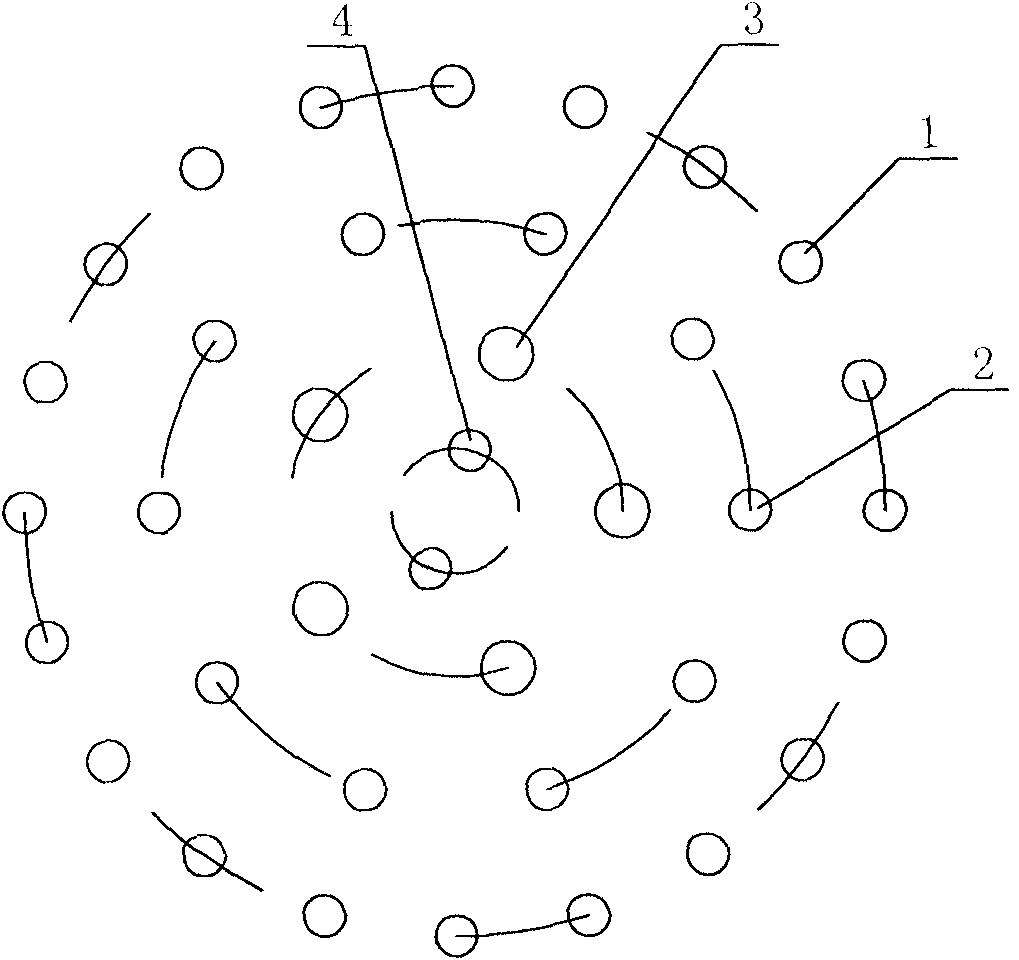

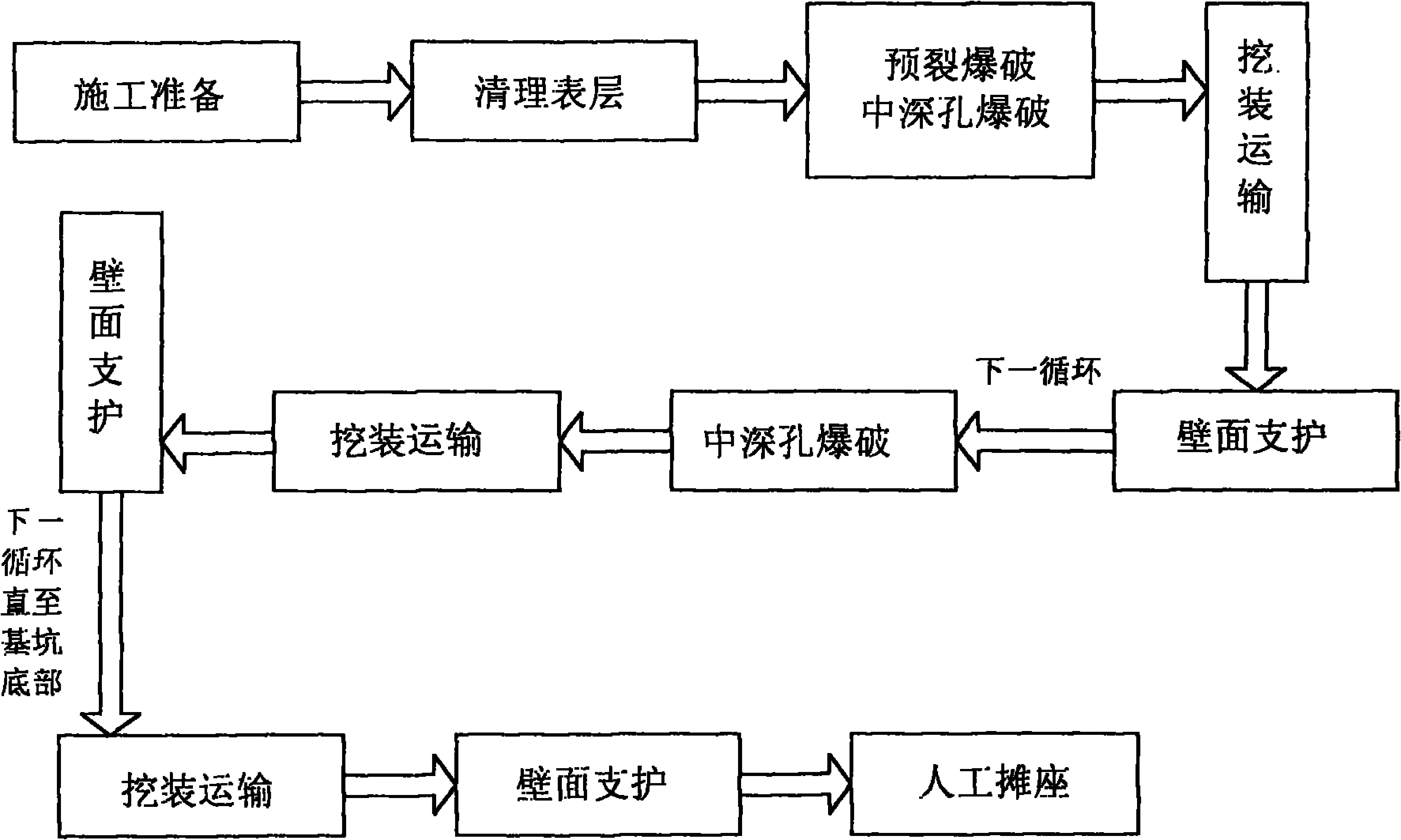

The invention discloses a method for molding a vertical wall of a deep foundation pit. The method comprises the following steps: drilling a plurality of presplit holes on a preset edge of the foundation pit and filling each presplit hole with a stick dynamite and a detonating fuse connected with an instant electric detonator outside the hole by adopting full-pit-depth one-step drilling molding; forming a buffer hole, a main explosion hole and a cutting hole in turn from outside to inside on the surface layer of the foundation pit; arranging segmented stick dynamites and non-electric millisecond difference detonators in the buffer hole, the main explosion hole and the cutting hole, wherein the non-electric millisecond difference detonators are connected with the instant electric detonators; after all the instant electric detonators are connected with each other in series, connecting all the instant electric detonators to a trigger; igniting a plurality of rows of blast holes at the same time and detonating the presplit hole, the cutting hole, the main explosion hole and the buffer hole in turn; after blasting, performing digging and transportation and wall surface timbering in sequence; blasting step by step to the bottom of a preset foundation pit; and manually repairing and scattering the bottom of the foundation pit. The method has the advantages of little construction difficulty, high protection safety, short construction period, stable engineering project quality and excellent comprehensive benefit.

Description

Forming Method of Straight Wall in Deep Foundation Pit technical field The invention relates to earthwork excavation and blasting technology, especially the technology for excavating ultra-deep foundation pits under complex geological conditions such as mudstone and sandstone, specifically a deep foundation pit for making a swirling pool of a steelmaking water treatment system Straight wall forming method. Background technique Foundation pit excavation is often encountered in construction engineering. According to different engineering geological conditions, such as rock mass structures composed of mudstone and sandstone, it is often necessary to use earthwork excavation and blasting technology in foundation pit excavation, especially in When excavating deep pools or deep pits with a diameter and depth of several tens of meters, due to the distribution of rocks in different layers, it is very difficult to use mechanical methods to break and excavate, and the technical and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E02D17/02E02D19/20F42D3/04

Inventor 姜元庆杨曙东罗欣

Owner CHONGQING IRON & STEEL (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com