Prefabricated steel-concrete combined beam structure and its implementation method

A combination of steel-concrete beams and steel-concrete combination technology, which is applied to structural elements, elongated structural components for load-bearing, building components, etc., can solve technical difficulties in anti-corrosion and fire prevention, high construction costs of steel structures, and concrete column connections Difficulties and other problems, to achieve the effect of reducing anti-corrosion and fire prevention and later maintenance costs, ease of construction, and reduced impact on the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

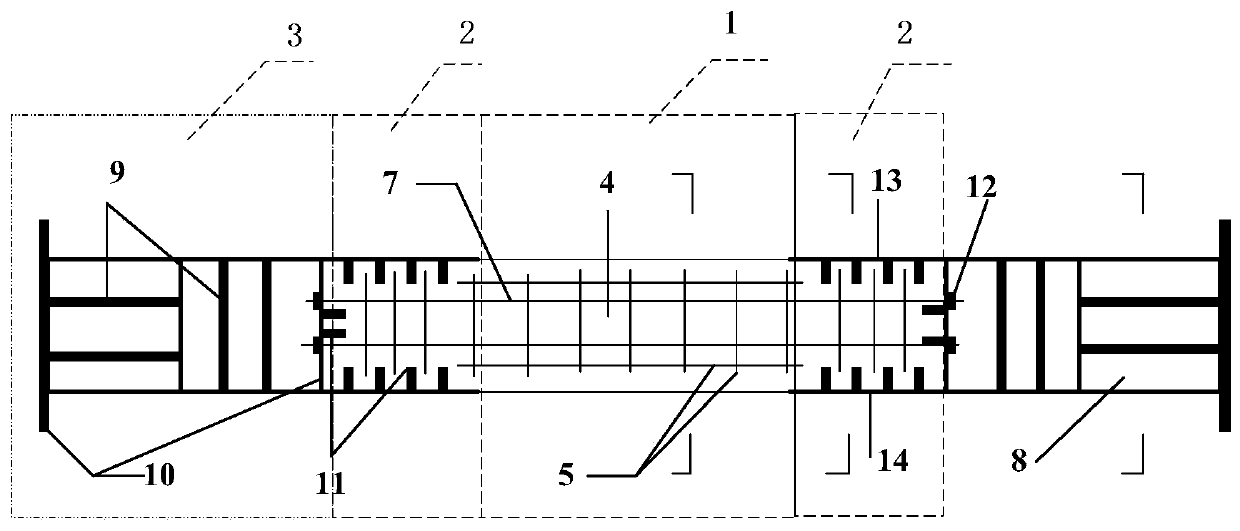

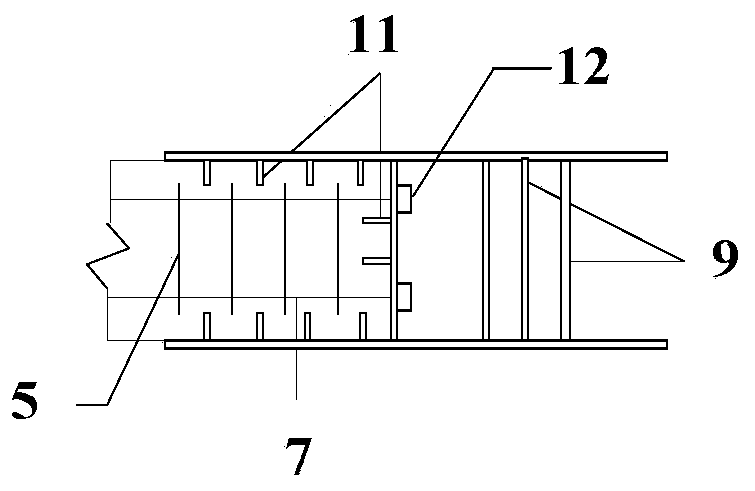

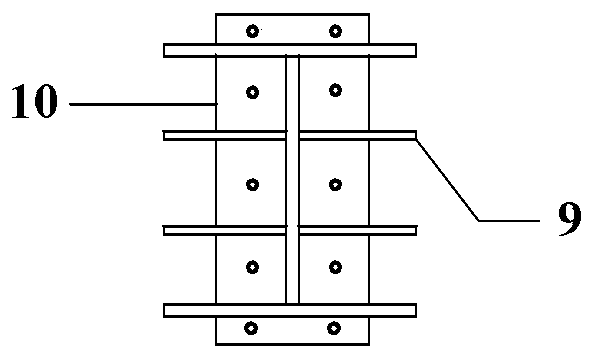

[0045] The layout of concrete beam 1, steel-concrete joint section 2 and short steel beam 3 in this embodiment is as follows Figure 1~3 shown. The concrete beam 1 is rectangular, 2-4 meters long, 450mm high and 250mm wide. The steel-concrete joint section 2 consists of shear keys 11, concrete 4, steel bars 5, stiffeners 9, end plates 10, anchoring systems 12, upper steel flange plates 13 and lower steel flange plates 14, and the length of the steel-concrete joint section is 250mm, height is 450mm, and width is 250mm; end plate 10, upper steel flange plate 13 and lower steel flange plate 14 are 20mm thick, the diameter of shear key 3 is 10mm, and the key length is 70mm. The spacing is calculated according to the specification.

[0046] The layout of the prestressed cable 7 in this embodiment in the steel-concrete composite beam is as follows: Figure 4~5 shown. Its specific coordinate position: the upper and lower prestressed cables 7 are 10cm away from the beam surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com