System for automatically identifying load of excavator

An identification system, excavator technology, applied in the direction of earth mover/shovel, construction, etc., can solve problems such as failure to reflect the power required for excavation, error in outlet pressure analysis, fuel loss environment, etc., to avoid fuel loss and formulate The effect of low power gear, fast processing speed and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

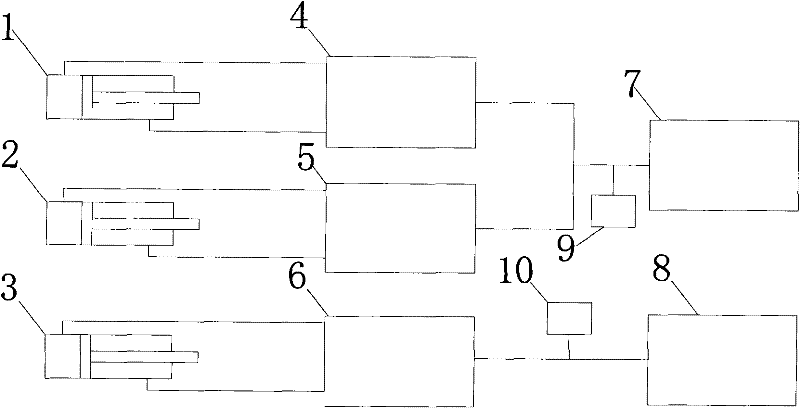

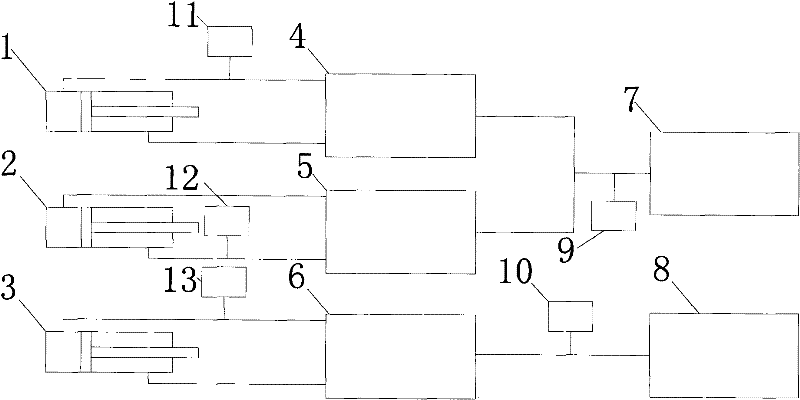

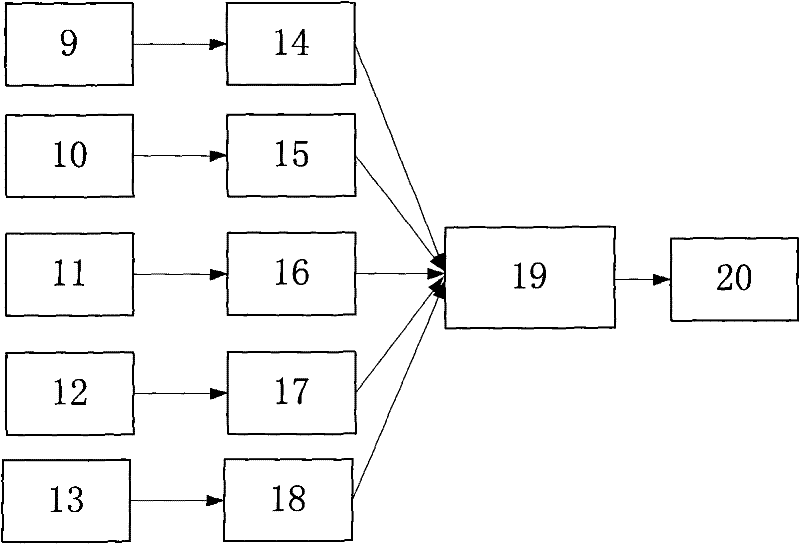

[0023] The principle of the present invention is: the present invention first judges whether the excavator is in the digging state, then collects the outlet pressures of the first main pump and the second main pump, and finally determines the working mode of the excavator and the output power of the engine. The digging state of the excavator can be reflected in the changes in the actions of the excavator bucket cylinder, boom cylinder and stick cylinder. Therefore, the present invention judges according to the oil pressure of the oil cylinder in the hydraulic system of the excavator. This solution only needs to add a pressure sensor to the original hydraulic system to judge the action of the excavator according to the change of the pressure output value, and the data processing is relatively simple. The excavator is in a working cycle, and the general related actions of each working state are analyzed as follows:

[0024] (1) Excavation process: the boom cylinder does not move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com