System for treating waste water discharge in three-flow-merge mode by using collection pipelines and discharge pipelines

A technology for treating waste water and pipelines, applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve problems such as inconvenient maintenance, inability to discharge lightly polluted water, unusable appliances, etc., to achieve smooth drainage, good water-saving effect, The effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

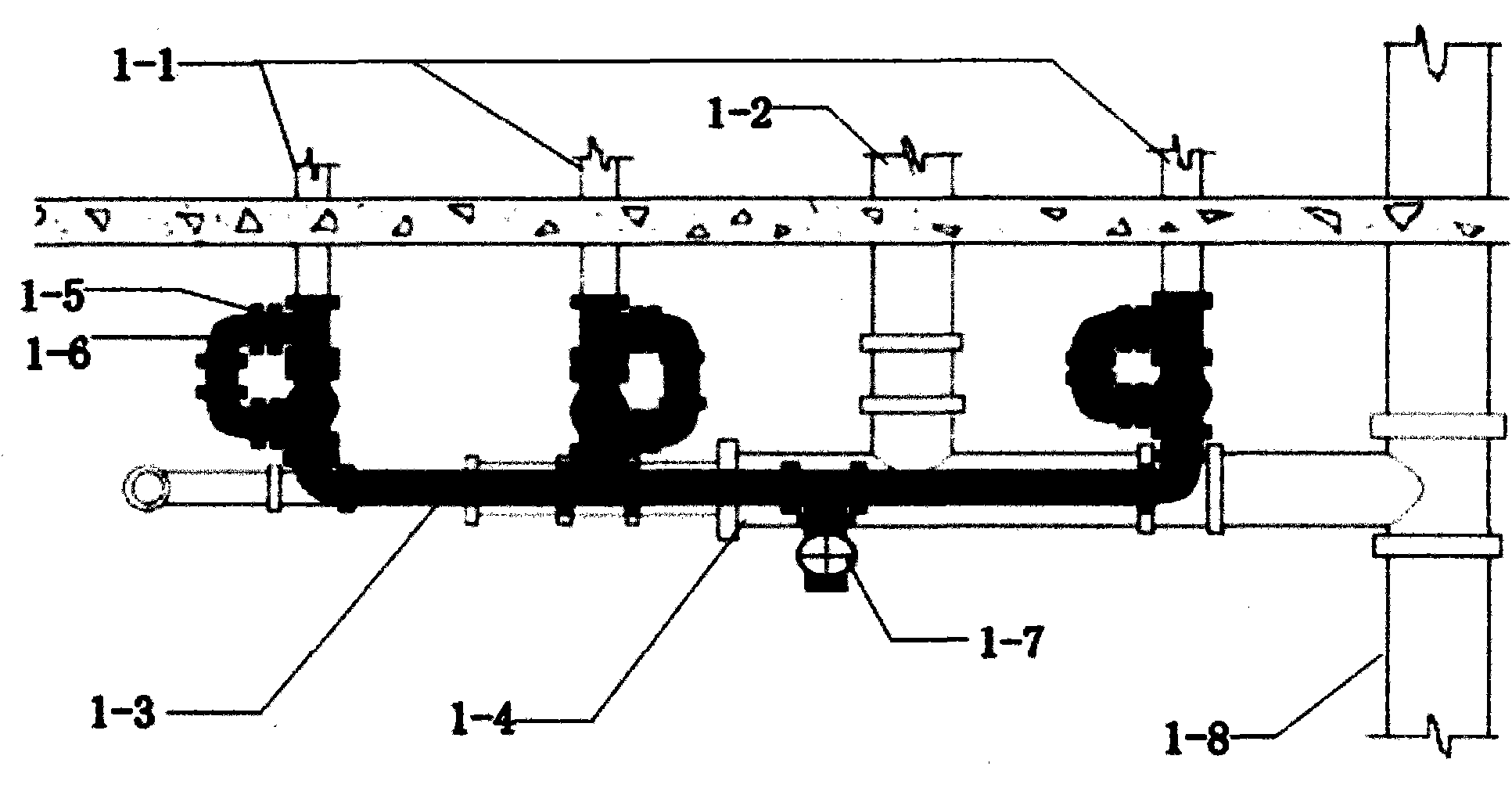

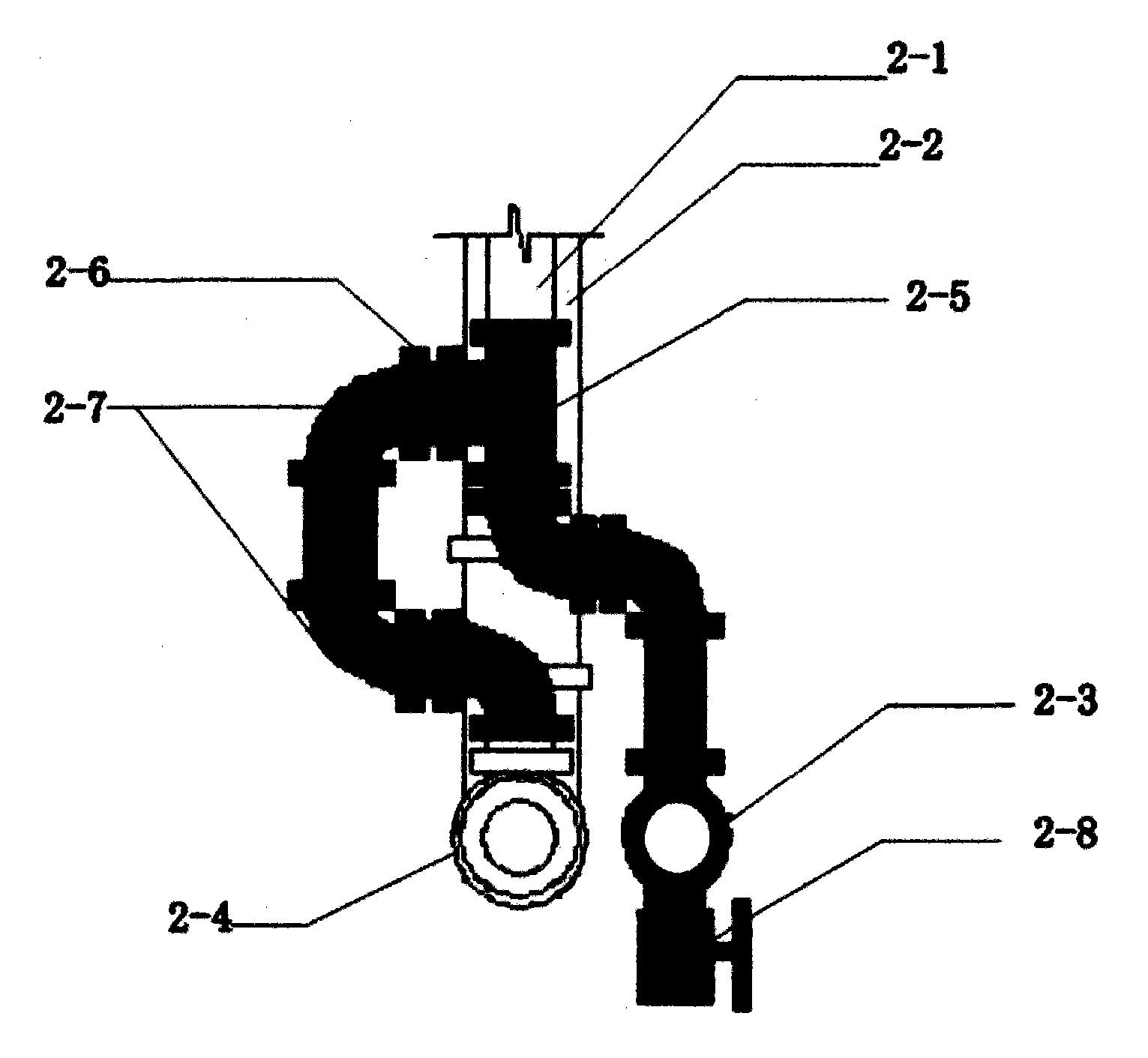

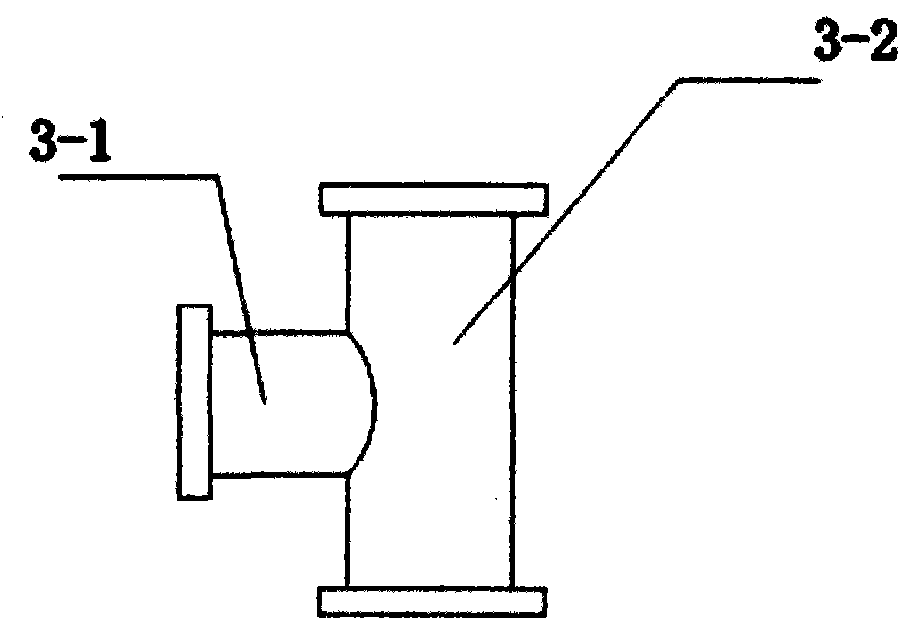

[0027] Embodiment one: see figure 1 and figure 2 , a system for treating waste water discharge in a three-flow manner of two collection and discharge pipes, including a light polluted water discharge pipe 1-1, a heavily polluted water discharge pipe 1-2, a lightly polluted water collection pipe 1-3, and a heavily polluted water collection pipe 1 -4, tee 1-5, elbow 1-6, control valve 1-7, main sewer pipe 1-8, when installing, connect the two ends of the three-way standpipe 2-5 to the light polluted water drain pipe 1- 1 is connected to the light polluted water collection pipe 1-3, the three-way horizontal pipe 2-6 is connected to the heavily polluted water collection pipe 1-4, and the control valve 2-8 is installed at the drain pipe outlet of the lightly polluted water collection pipe 2-3 , Elbow 1-6 is used when the pipeline turns to connect, and the position of the three-way horizontal pipe 2-6 is higher than that of the heavily polluted water collection pipe 2-4. The coll...

Embodiment 2

[0028] Embodiment two: see figure 1 , figure 2 and Figure 5 , the embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the lightly polluted water collection pipe 5-3 is installed vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com