Two-piece all-hydraulic tunnel drilling machine

A tunnel drilling rig, split technology, applied in tunnels, drilling equipment, earthwork drilling and other directions, can solve the problems of high operation cost, inconvenient use, low use cost, etc., to improve work efficiency, convenient operation, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

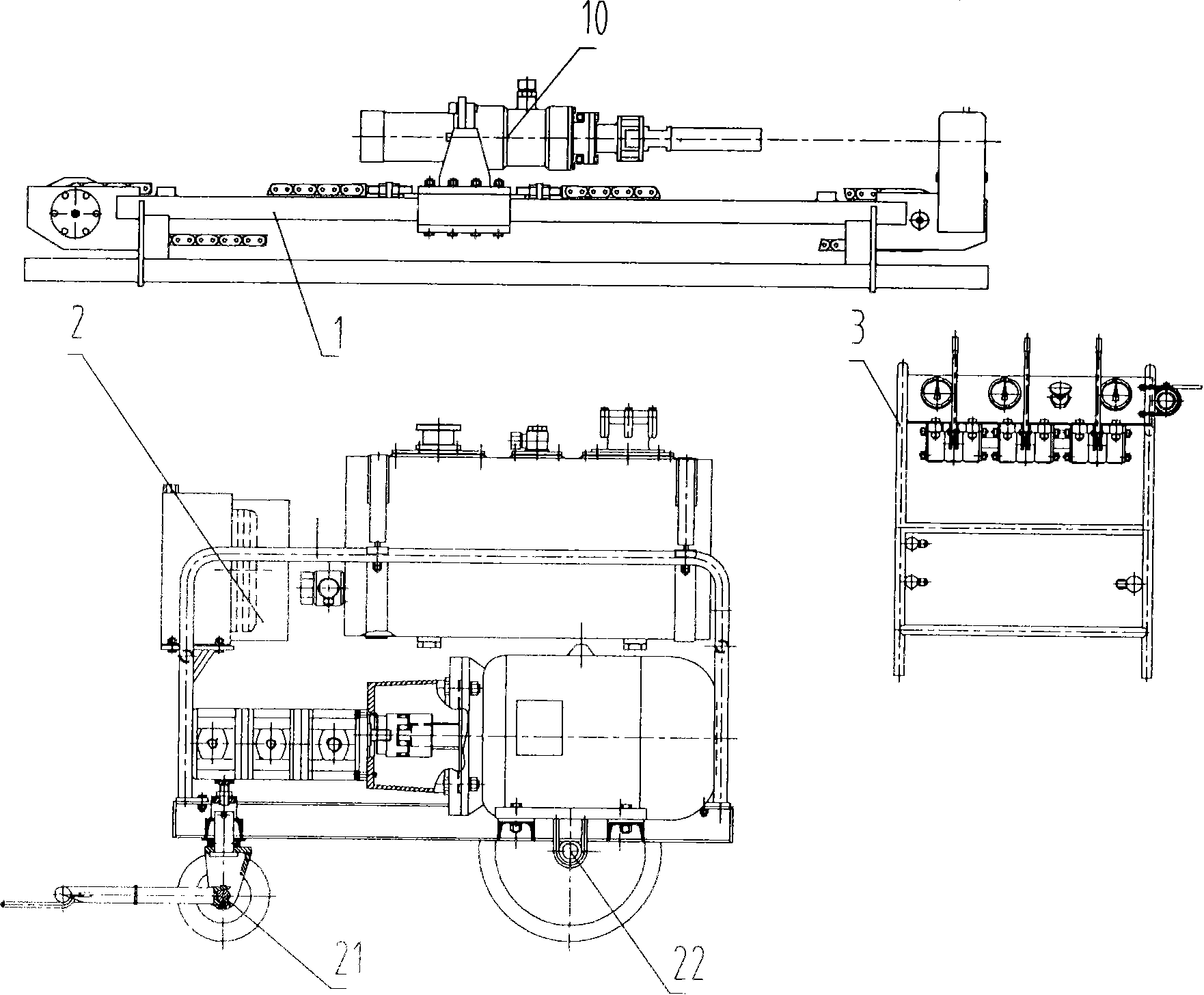

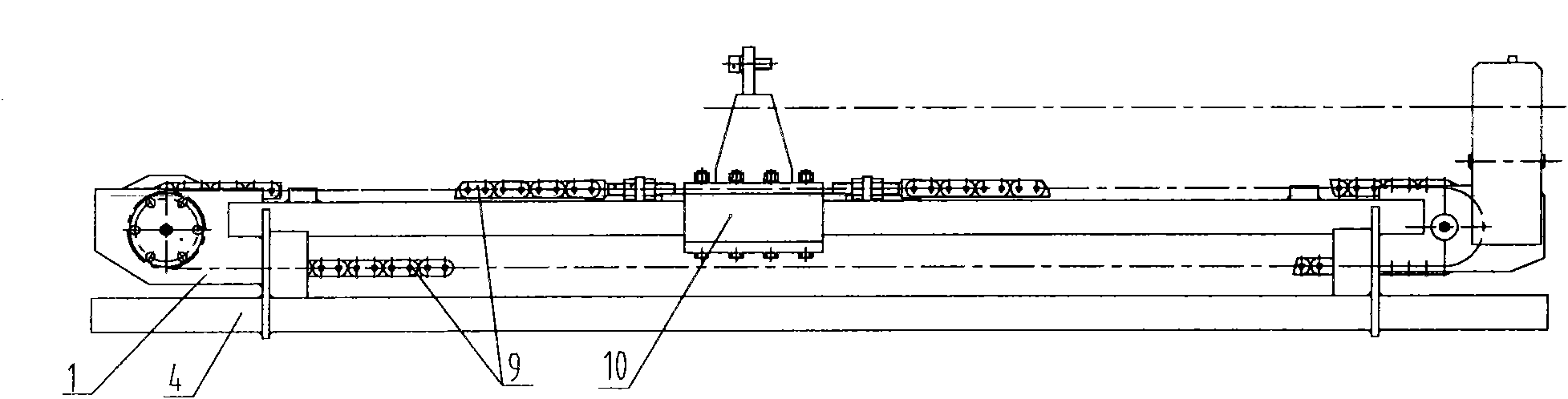

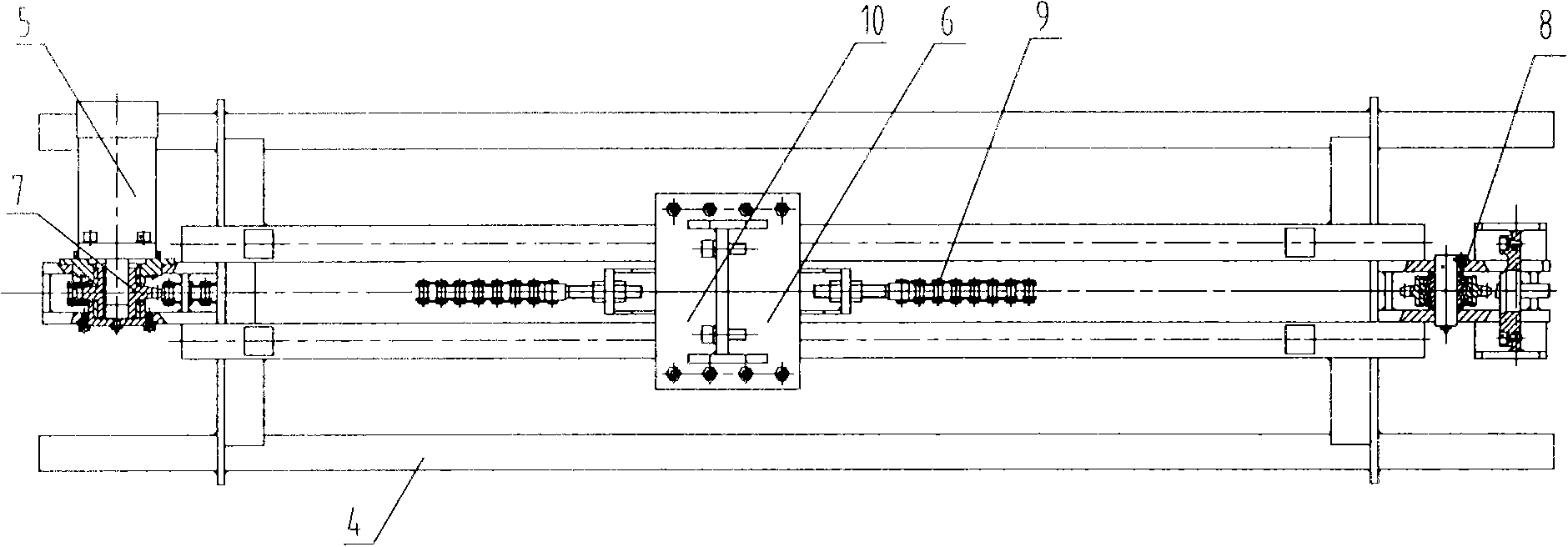

[0021] Such as figure 1 Among them, the split-type full hydraulic tunnel drilling rig of the present invention includes three parts: the power head and the mast 1, the hydraulic pump station 2 and the control console 3, wherein the power head and the mast 1 and the hydraulic pump station 2 are set separately, and the console 3 Can be separately arranged in split type, become an independent part, also can be arranged on power head and mast device 1 or hydraulic pump station 2; Power head and mast device 1, hydraulic pump station 2 and console 3 are composed of three parts. According to the working requirements of the drilling rig, hydraulic oil pipes (including necessary control valves, control wires, and signal feedback lines) are used between each part. etc.) to form the pipeline connection; under the operation and control of the control valve (mainly the hydraulic reversing valve and related buttons) of the console 3, the high-pressure hydraulic oil generated by the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com