Piston connecting rod structure of internal-combustion engine

A technology for pistons, connecting rods and internal combustion engines, which is applied in the direction of pistons, connecting rods, mechanical equipment, etc., can solve the problems of internal combustion engine life and adverse effects on performance, and achieve the effects of reducing excess mass, reducing inertial force, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

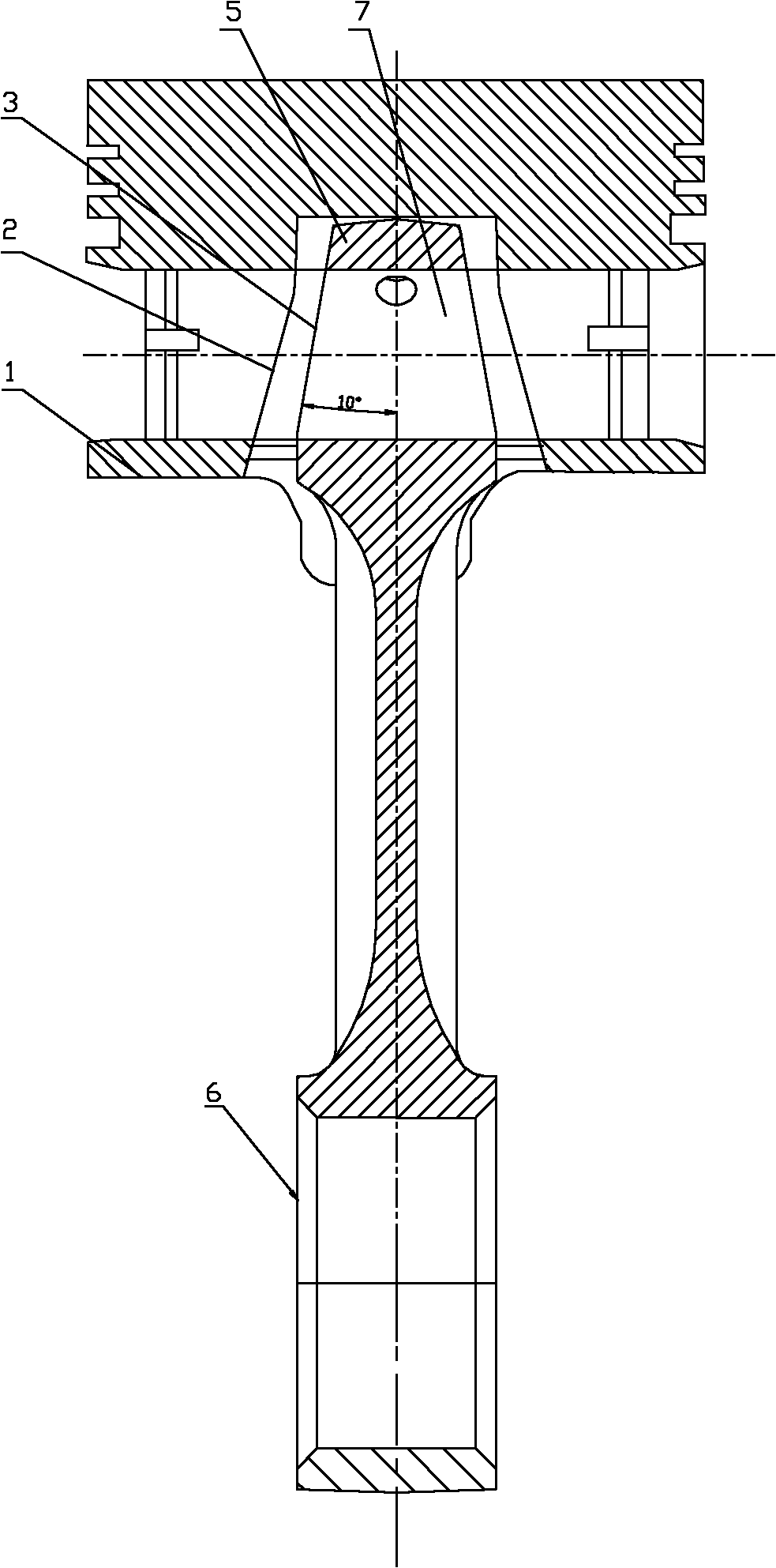

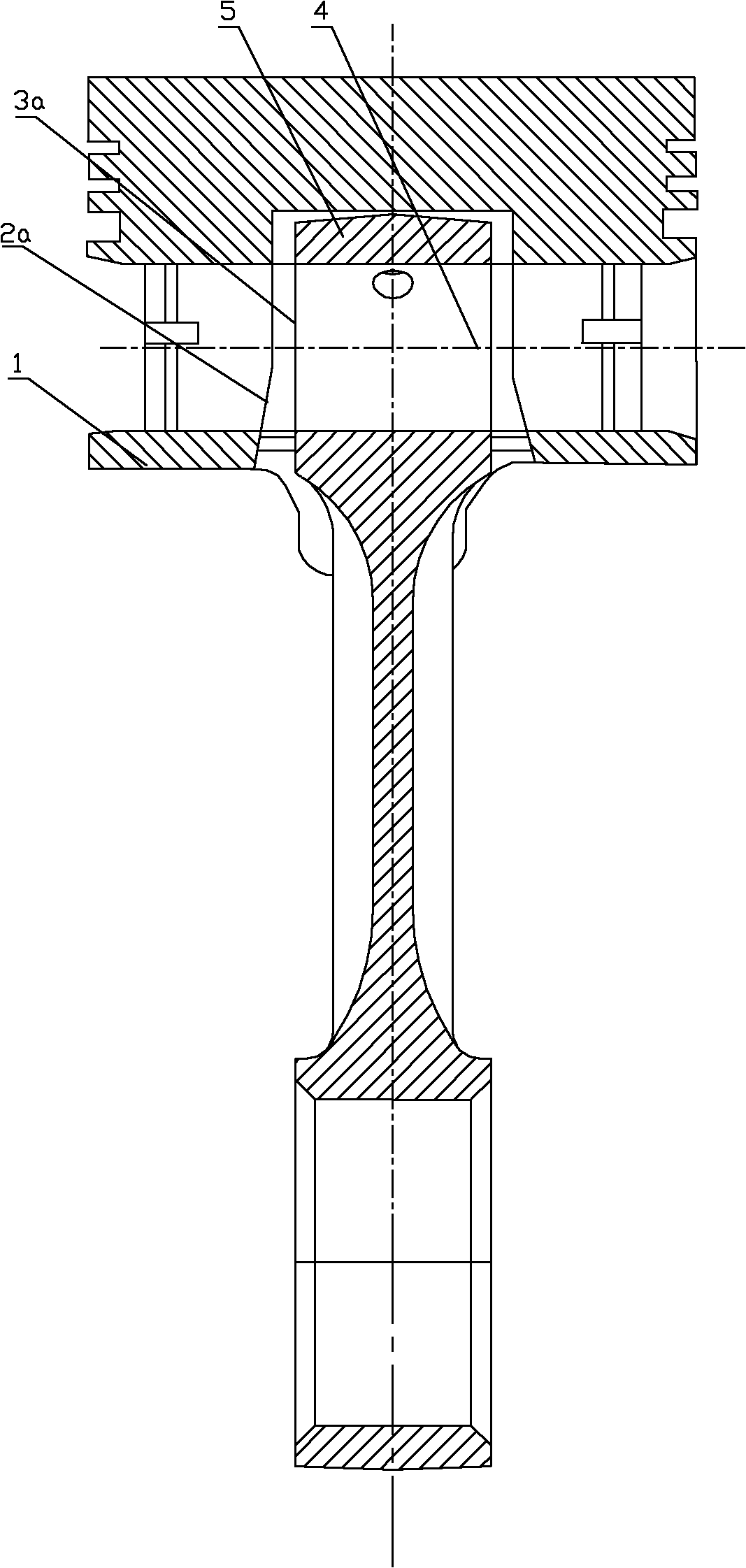

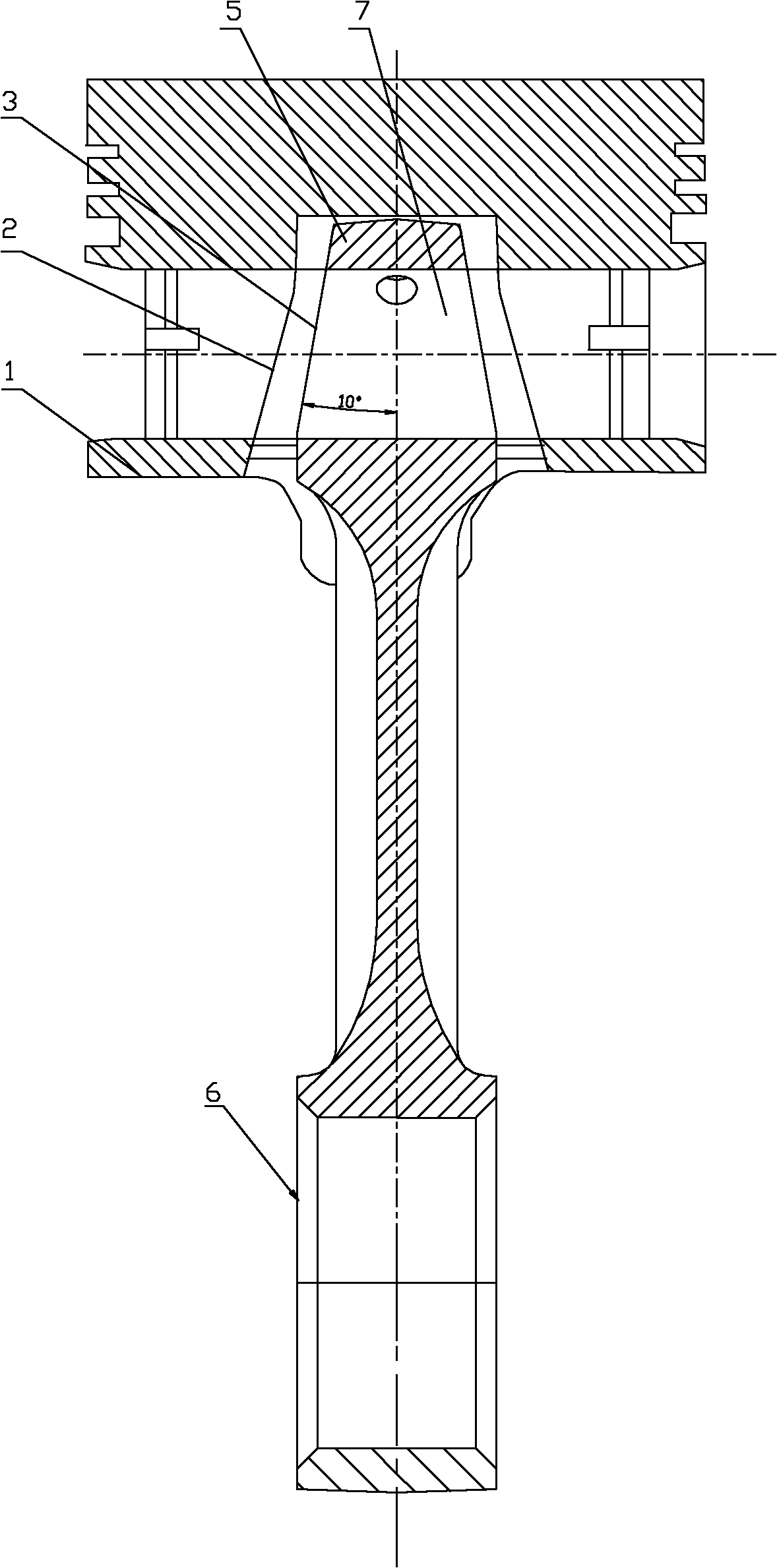

[0014] refer to figure 1 , the piston 1 of the internal combustion engine is connected with the small end 5 of the connecting rod through the piston pin, and the large end 6 of the connecting rod is connected with the crankshaft through the crank pin. When the internal combustion engine is working, the piston drives the crankshaft to rotate through the connecting rod. The left-right symmetrical side of the connecting rod small end 5 is set as the inclined surface 3, so that the connecting rod small end 5 forms a wedge-shaped head, which can minimize the excess mass of the connecting rod under the premise of satisfying the strength and rigidity of the connecting rod. The angle between the connecting rod small end slope 3 and the central axis of the connecting rod is 5° to 20°. Through this angle parameter, it can ensure that the strength and rigidity of the connecting rod small end will not be weakened, and the excess mass will be subtracted. In this embodiment, the angle betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com