Ink powder special for Kyocera digital printing and copying machine without bottom ash and preparation method thereof

A technology for digital printing and copiers, applied in printing, inking devices, electrographics, etc., can solve the problems of easy generation of back ash, and the distribution of charge cannot be too wide, and achieve moderate image density, strong practicability, and enhanced compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

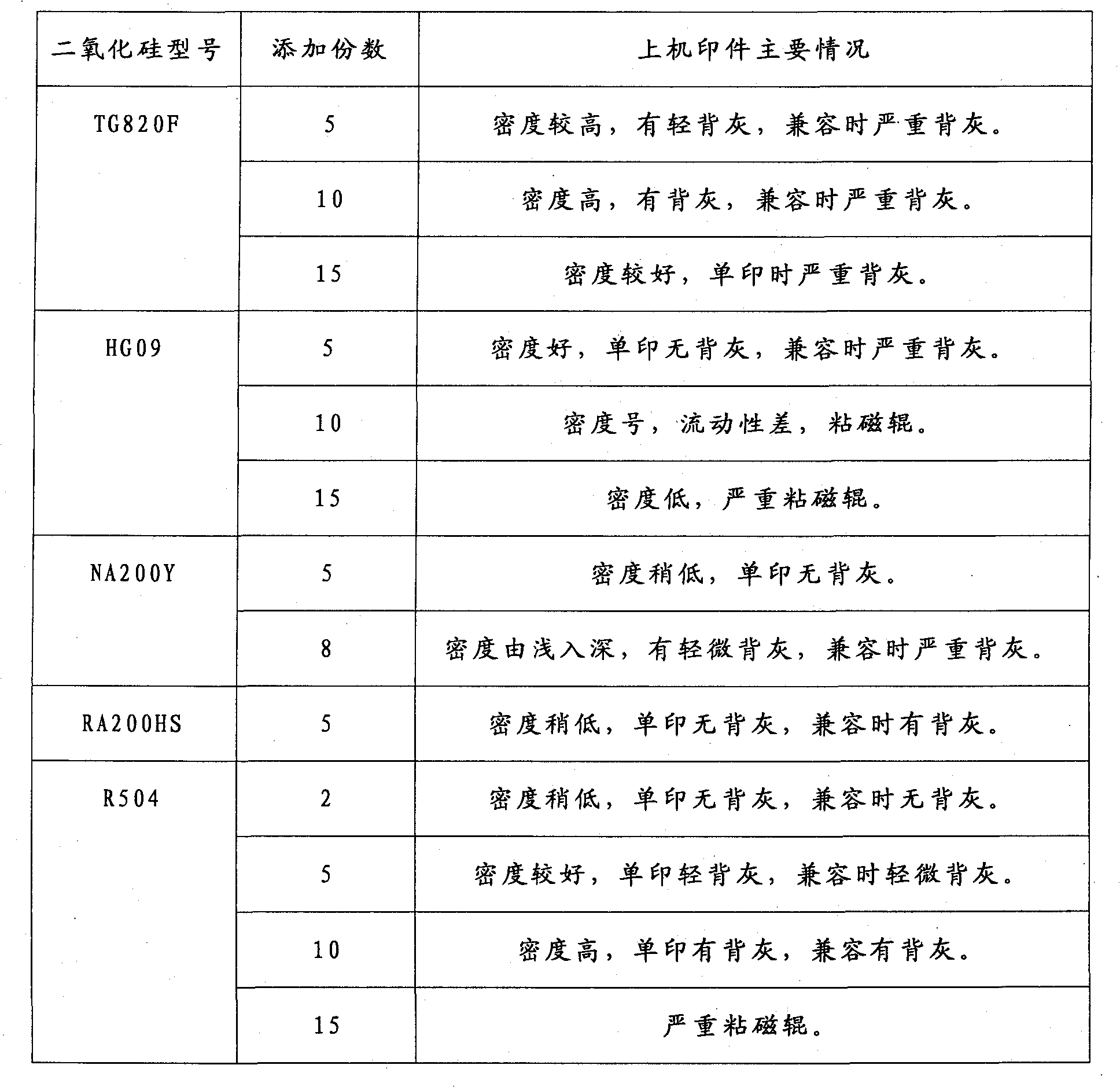

Method used

Image

Examples

Embodiment 1

[0031] The toner material that is 1000 parts by weight (for existing Kyocera digital printers, the toner used by copiers, the same below) is pulverized and classified and added with 2 parts of electropositive silica R504, and 3 parts of poly Methyl methacrylate MP1000, 0.5 parts by weight of titanium dioxide NKT90, and then put the mixture into a mixer and mix evenly to obtain the toner of the present invention.

[0032] The special toner of the invention has no back dust and bottom dust on printed parts, has good compatibility and good powder fluidity.

Embodiment 2

[0034]Add the electropositive silicon dioxide R504 that is 10 parts by weight after pulverizing and grading the toner material that is 1000 parts by weight, polymethyl methacrylate MP1000 that is 5 parts by weight, titanium dioxide NKT90 that is 1.5 parts by weight, and then the mixture Throw it into a mixer and mix evenly to obtain the toner of the present invention.

[0035] The special toner of the invention has no back dust and bottom dust on printed parts, has good compatibility and good powder fluidity.

Embodiment 3

[0037] Add the electropositive silicon dioxide R504 that is 5 parts by weight after pulverizing and grading the toner material that is 1000 parts by weight, polymethyl methacrylate MP1000 that is 4 parts by weight, titanium dioxide NKT90 that is 1.0 parts by weight, and then the mixture Throw it into a mixer and mix evenly to obtain the toner of the present invention.

[0038] The special toner of the invention has no back dust and bottom dust on printed parts, has good compatibility and good powder fluidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com