Manufacturing apparatus for semiconductor device, controlling method for manufacturing apparatus, and storage medium storing control program for manufacturing apparatus

A technology of a manufacturing device and a control method, which is applied in semiconductor/solid-state device manufacturing, photolithography process exposure devices, electrical components, etc., can solve problems such as pattern size differences, actual exposure differences, etc., and achieve the effect of suppressing deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

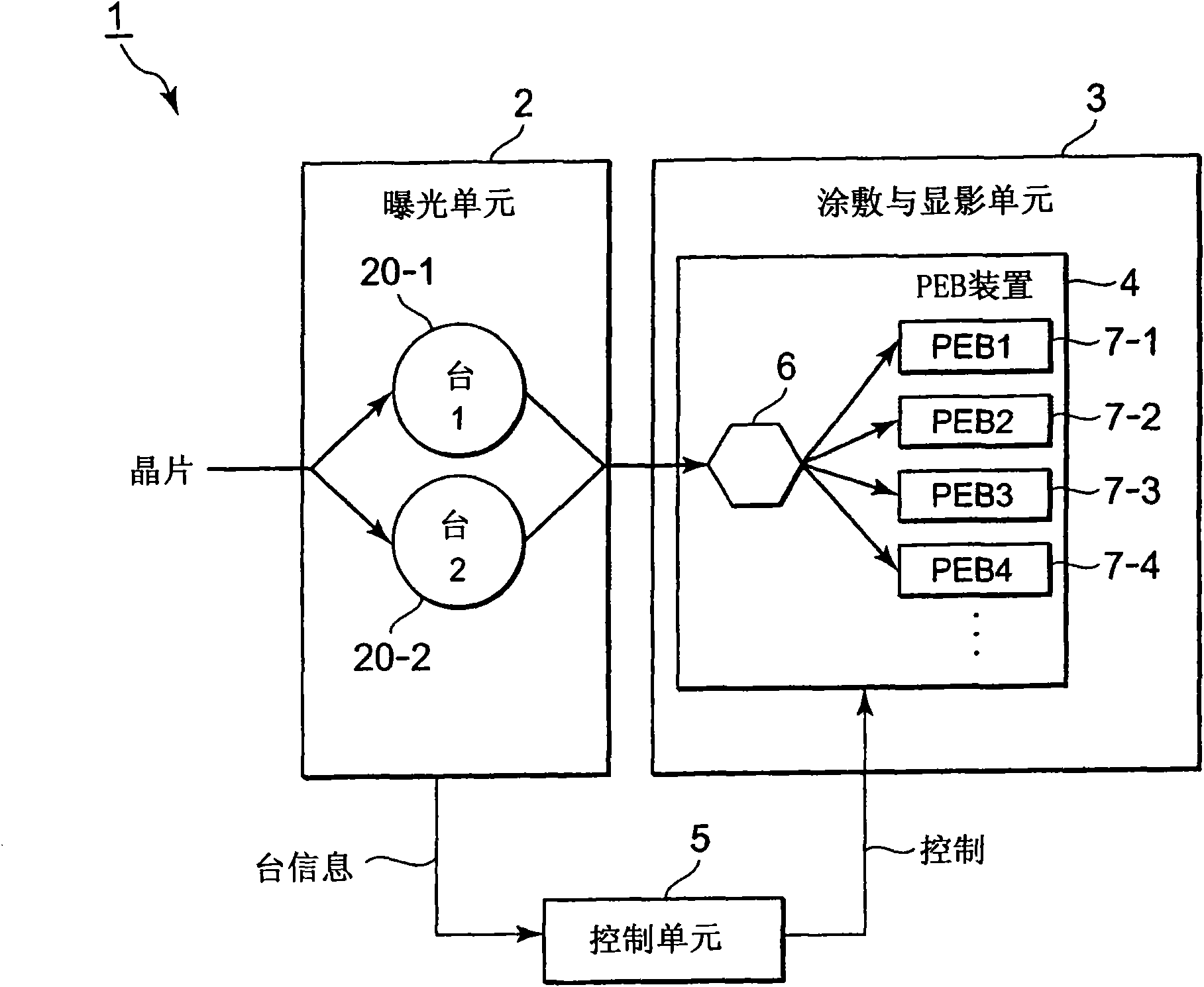

[0023] Hereinafter, embodiments of the present invention are described with reference to the drawings. figure 1 is a configuration diagram showing the semiconductor device manufacturing apparatus 1 according to this embodiment.

[0024] Such as figure 1 As shown, the semiconductor device manufacturing apparatus 1 includes an exposure unit 2 , a coating and developing unit 3 and a control unit 5 . The coating and developing unit 3 includes a post exposure bake (PEB) device 4 (heating device) and a developing device (not shown).

[0025] The exposure unit 2 is a device for exposing a wafer on which a resist film is formed. In general, the exposure unit 2 exposes (to light) a resist film formed on a wafer through a photomask on which a predetermined pattern (so as to include transparent portions and opaque portions) is formed. As the resist, a chemically amplified resist is used. The exposure unit 2 has a plurality (two) of exposure stages 20 (20-1 and 20-2). Each exposure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com