Method for producing r-t-b sintered magnet

A technology of sintered magnets and manufacturing methods, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of difficulty in high-precision grinding, long processing time, large processing load, etc. Deviation and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

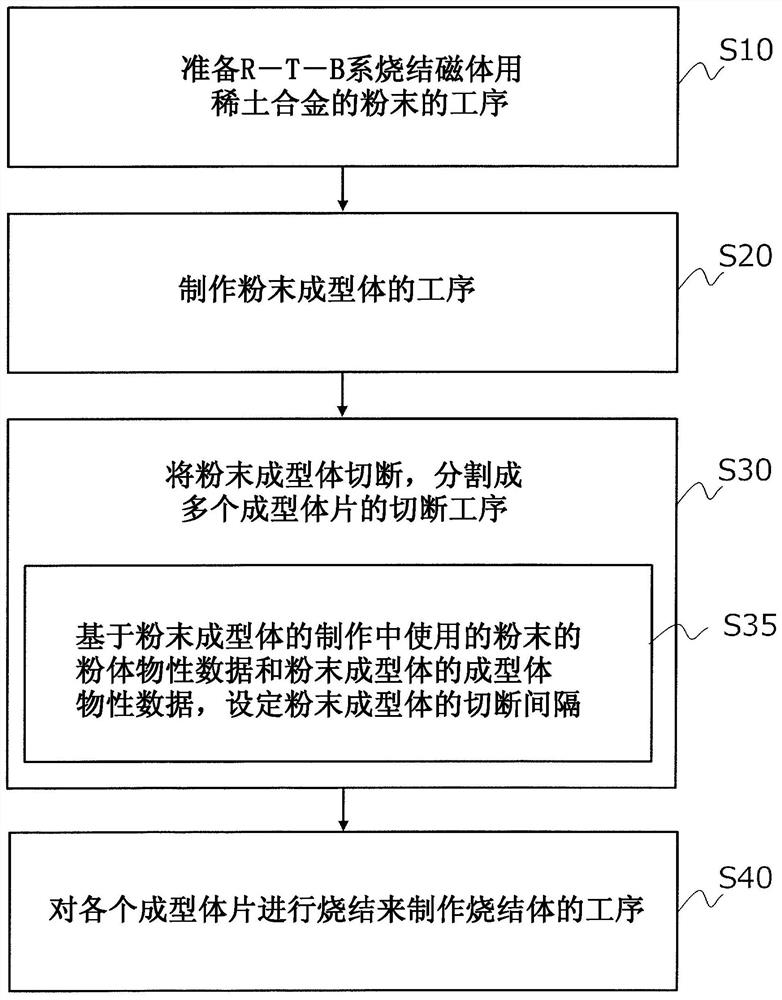

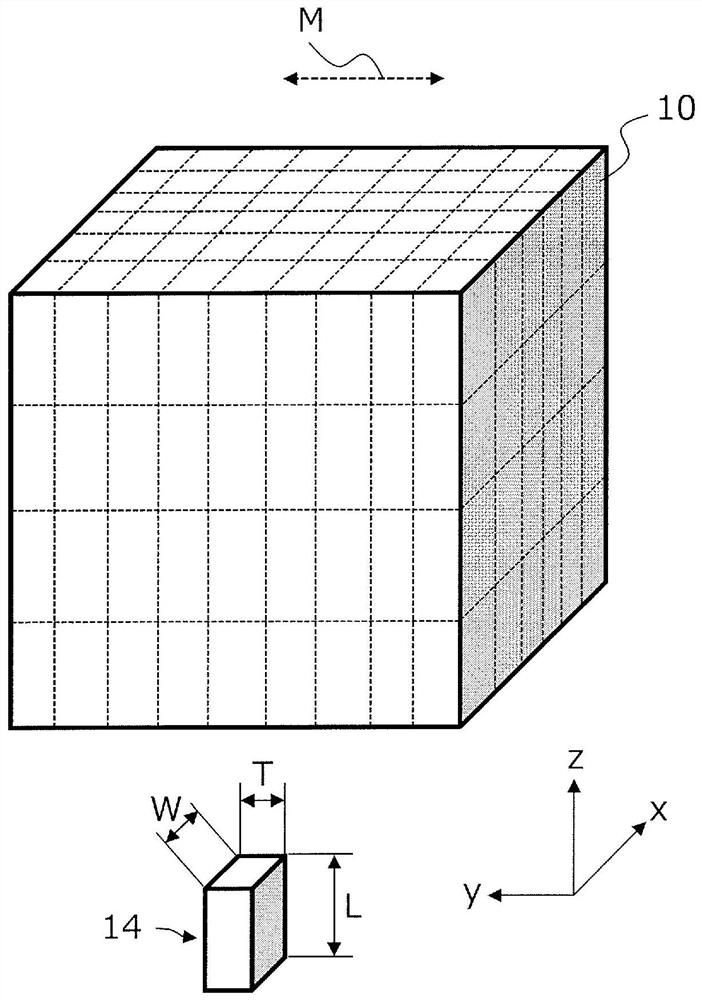

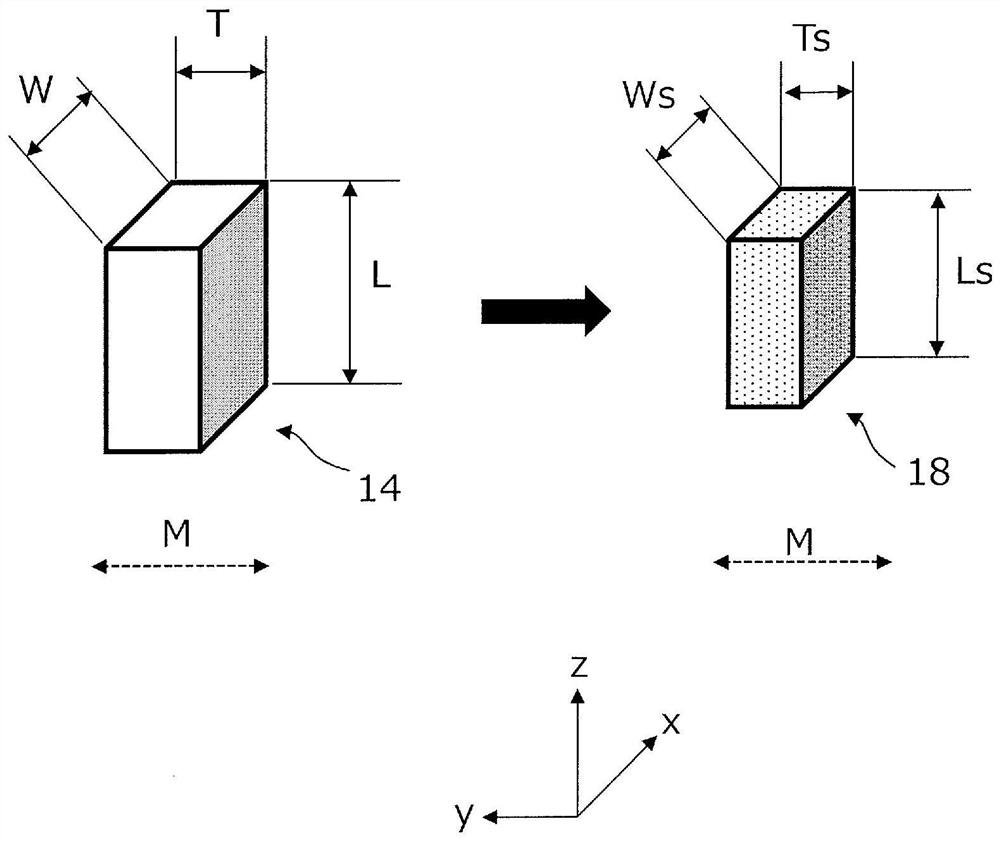

[0027] When a powder compact is cut to prepare a plurality of compact pieces, and each compact piece is sintered to produce a sintered body, shrinkage as described above occurs. The dimensional difference between the molded body and the sintered body with respect to the size of the molded body is defined as "shrinkage rate". The shrinkage rate is, for example, about 30%, but its specific value can vary depending on parameters such as powder composition, particle size, and molding density of the powder compact. The size of the obtained sintered body may vary by, for example, about 2 to 5% due to fluctuations in shrinkage.

[0028] When cutting a powder compact with a wire saw or the like and dividing it into a plurality of pellets and then sintering, conventionally, the shrinkage rate due to sintering is collected as basic data, and the powder is set based on the maximum value of the collected shrinkage rate. The cutting width (cutting interval) of the molded body. In other w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com