Handheld dehider

A peeler, hand-held technology, applied in peeling tools, slaughter accessories, portable mobile devices, etc., can solve problems such as shortening the life of parts in the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

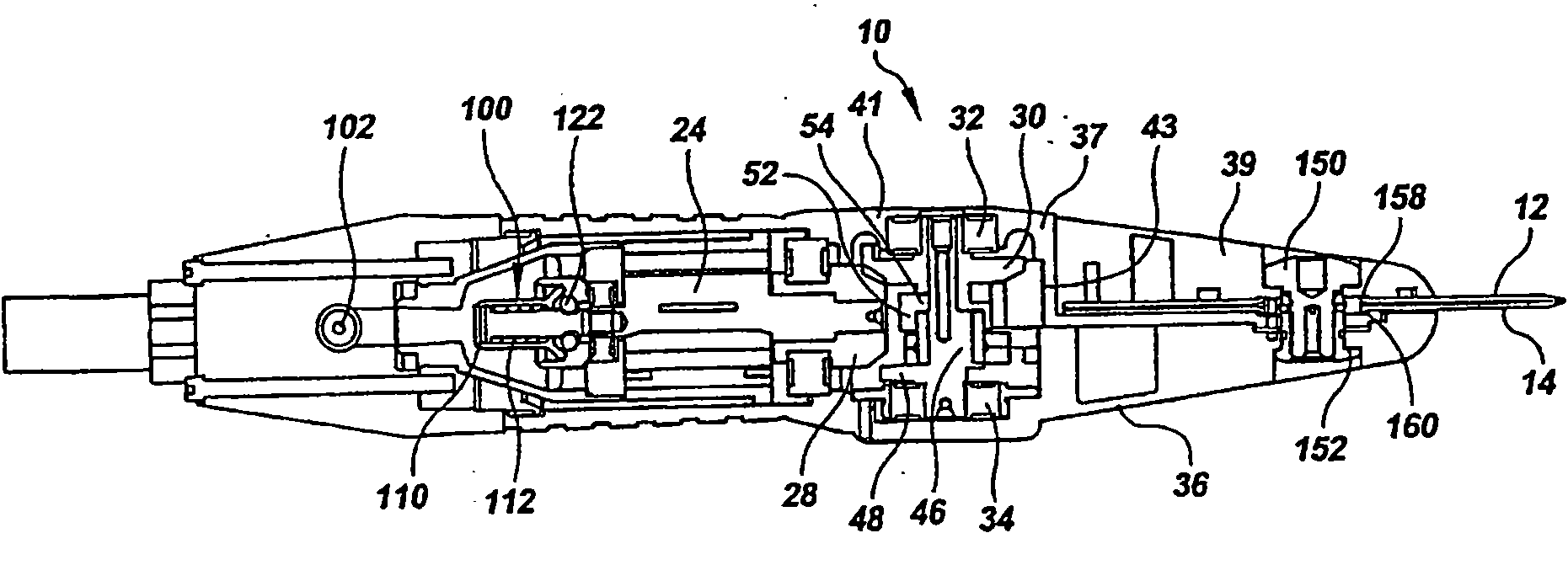

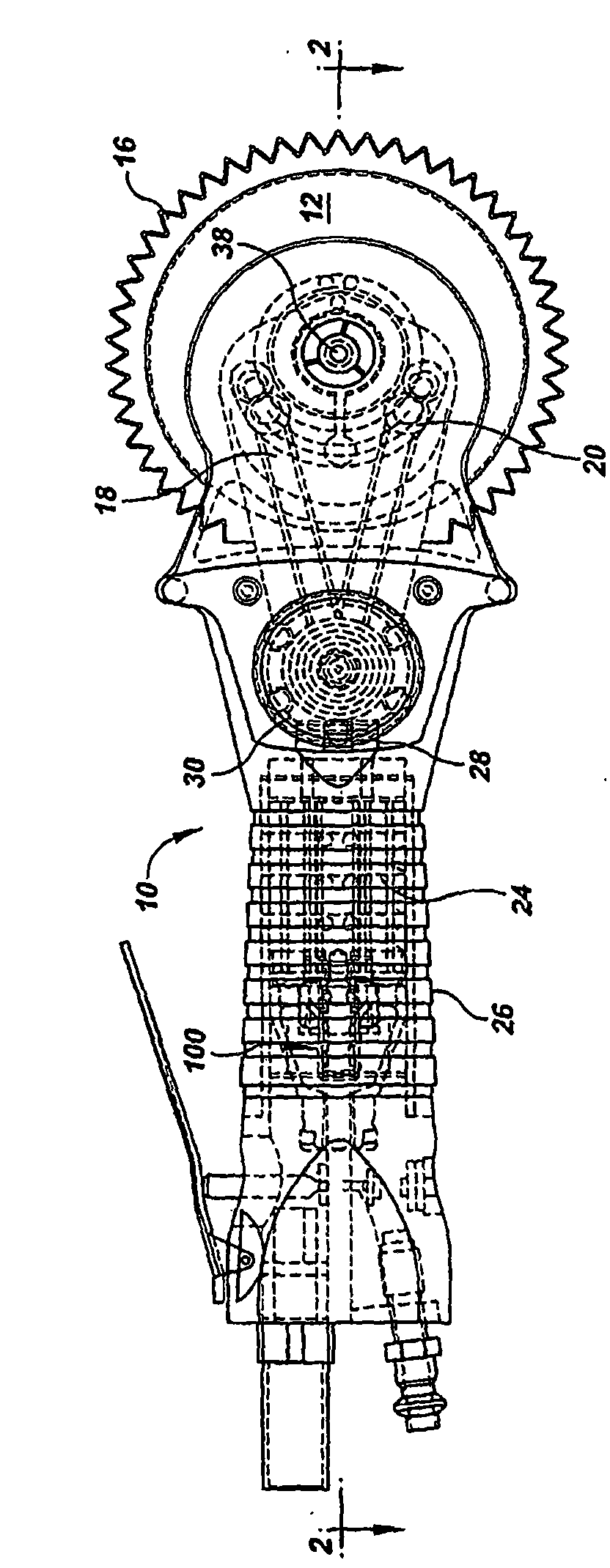

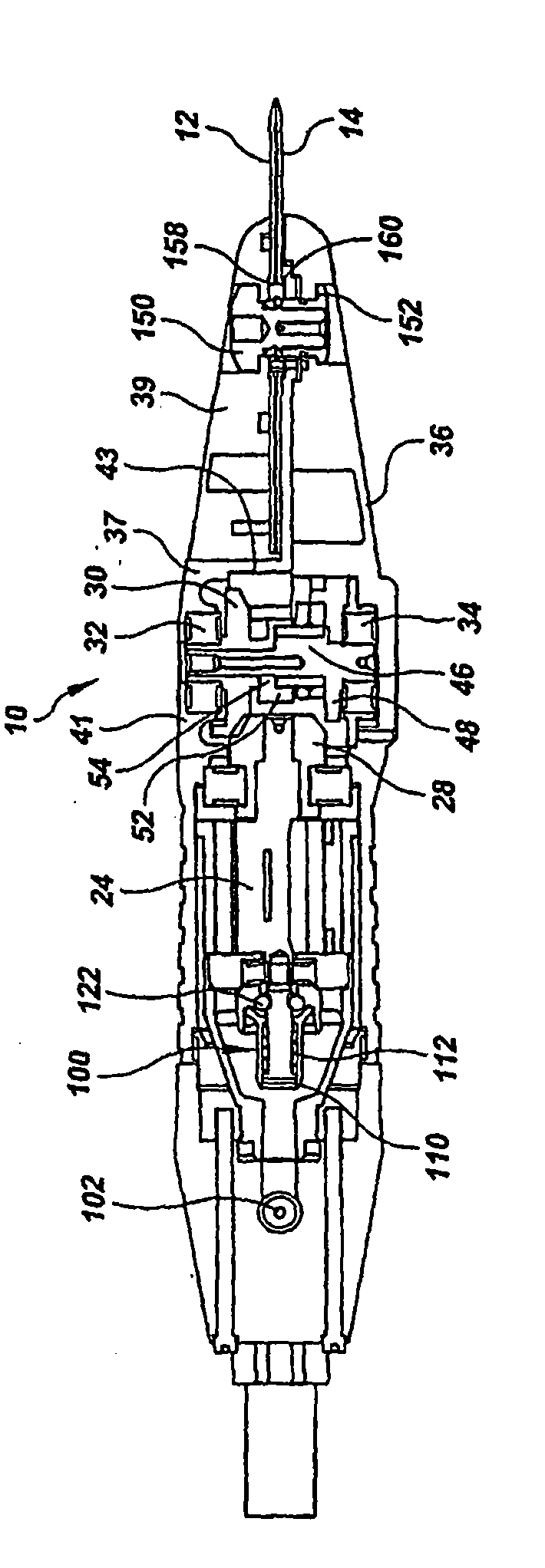

[0044] In describing the preferred embodiment of the invention, reference will be made herein to Figures 1-10 of the drawings, wherein like reference numerals indicate like features of the invention.

[0045] 1 and 2 show a hand-held dehider 10 according to a first embodiment of the invention. The debarker 10 includes a pair of adjacent cutting discs 12 and 14 having teeth 16 positioned around the periphery of each disc. The cutting discs 12, 14 are driven in counter-cutting oscillation by a pair of push rods 18, 20 via an eccentric shaft 22 (best seen in Figure 3).

[0046] The eccentric shaft 22 is driven by an air motor 24 located in a handle 26 of the tool housing. Motor 24 drives pinion 28 which engages and turns main drive gear 30 . The main drive gear 30 is mounted on the eccentric shaft 22 such that rotation of the motor and pinion turns the main drive gear and eccentric shaft to drive the push rod and cutting disc.

[0047] The eccentric shaft 22 is held between a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com