Method for preparing sweet potato whole powder

A sweet potato powder and sweet potato technology, which is applied in food preparation, food preservation, fruit and vegetable preservation, etc., can solve the problem of intensifying β-carotene isomerization and protein denaturation, which is not conducive to the retention of sweet potato nutrients, and aggravates the loss of nutrients in sweet potatoes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1. Preparation of whole sweet potato powder

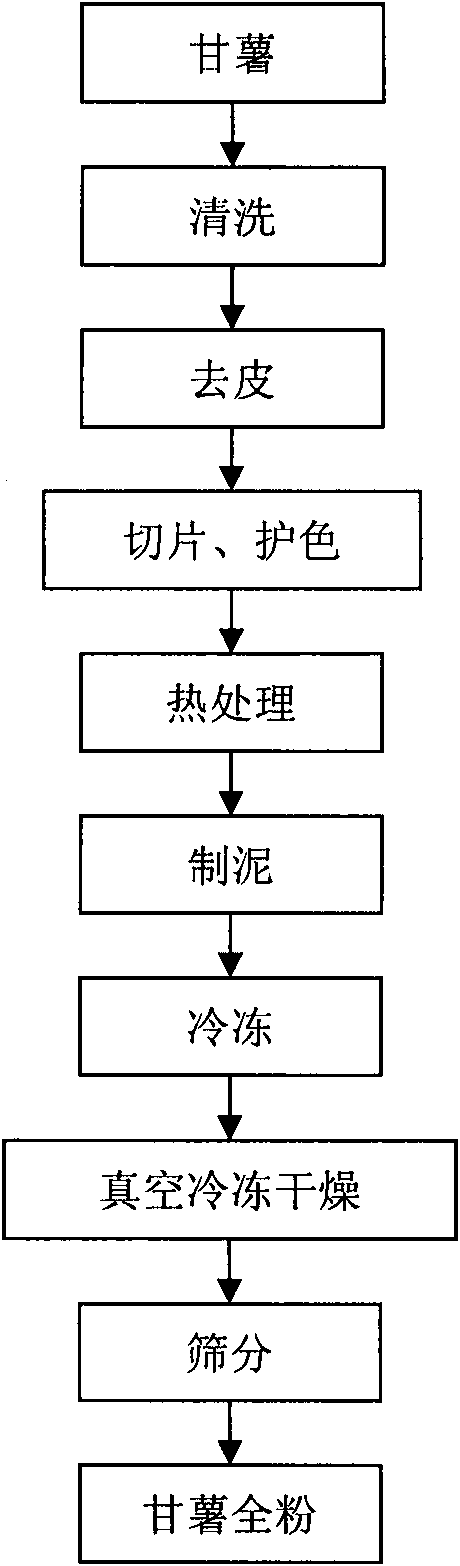

[0031] The process flow chart of the preparation of whole sweet potato powder is shown in Figure 1. The method for preparing the whole sweet potato powder will be described below in conjunction with specific examples.

[0032] In order to ensure that the prepared sweet potato powder has better color and higher yield, sweet potato varieties with low soluble sugar content, low reducing sugar content, low polyphenol oxidase activity and high dry rate are selected as raw materials to eliminate sprouting and mildew. Potato wedges.

[0033] 1) Wash fresh sweet potatoes (No Sugar No. 1 from Hebei Academy of Agricultural Sciences and Shang 0110-3 cultivated by Xuzhou Sweet Potato Research Center) separately to remove the sludge on the surface;

[0034] 2) Peel the sweet potato after washing in step 1);

[0035] 3) Cut the peeled sweet potato of the above step 2) into sweet potato slices of 9-11 mm;

[0036] 4) Immerse the sweet potat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com