Lichee pericarp girdling machine

A lychee peel and ring cutting machine technology is applied in the fields of vegetable or fruit peeling, food science, application, etc., which can solve the problems of unguaranteed product quality, high work intensity, polluted lychee meat, etc. Practical simplicity, easy to implement effects

Active Publication Date: 2010-08-25

合浦果香园食品有限公司

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a kind of litchi peel ring cutting machine, which can cut the litchi peel for a week, laying the foundation for the next peeling and core removal process, thereby overcoming the current technical problems of litchi peeling and solving the manual operation of litchi peeling And the pollution of lychee meat that exists in the operation of small equipment, the work intensity is high, the operation is cumbersome, and the product quality cannot be guaranteed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

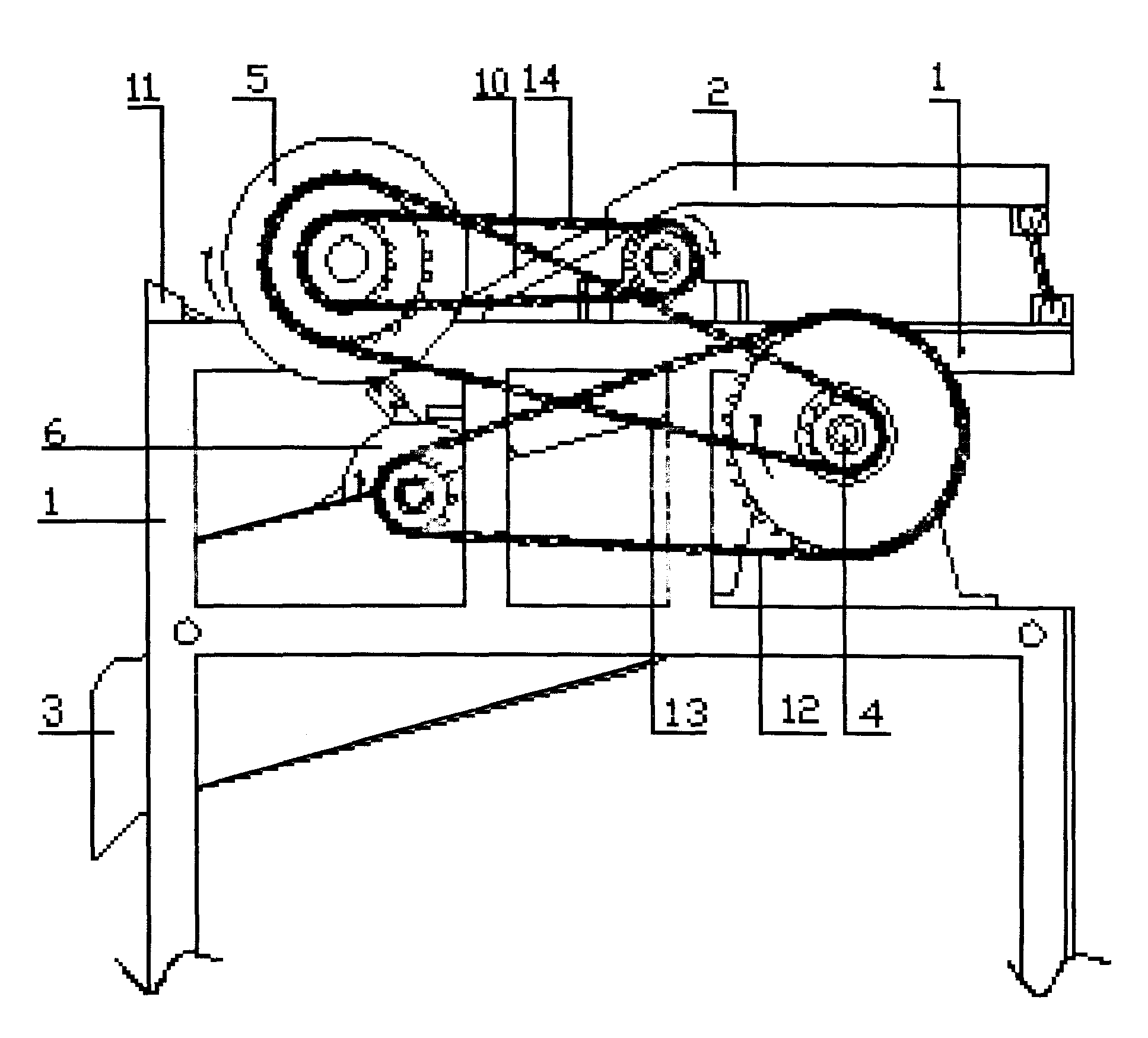

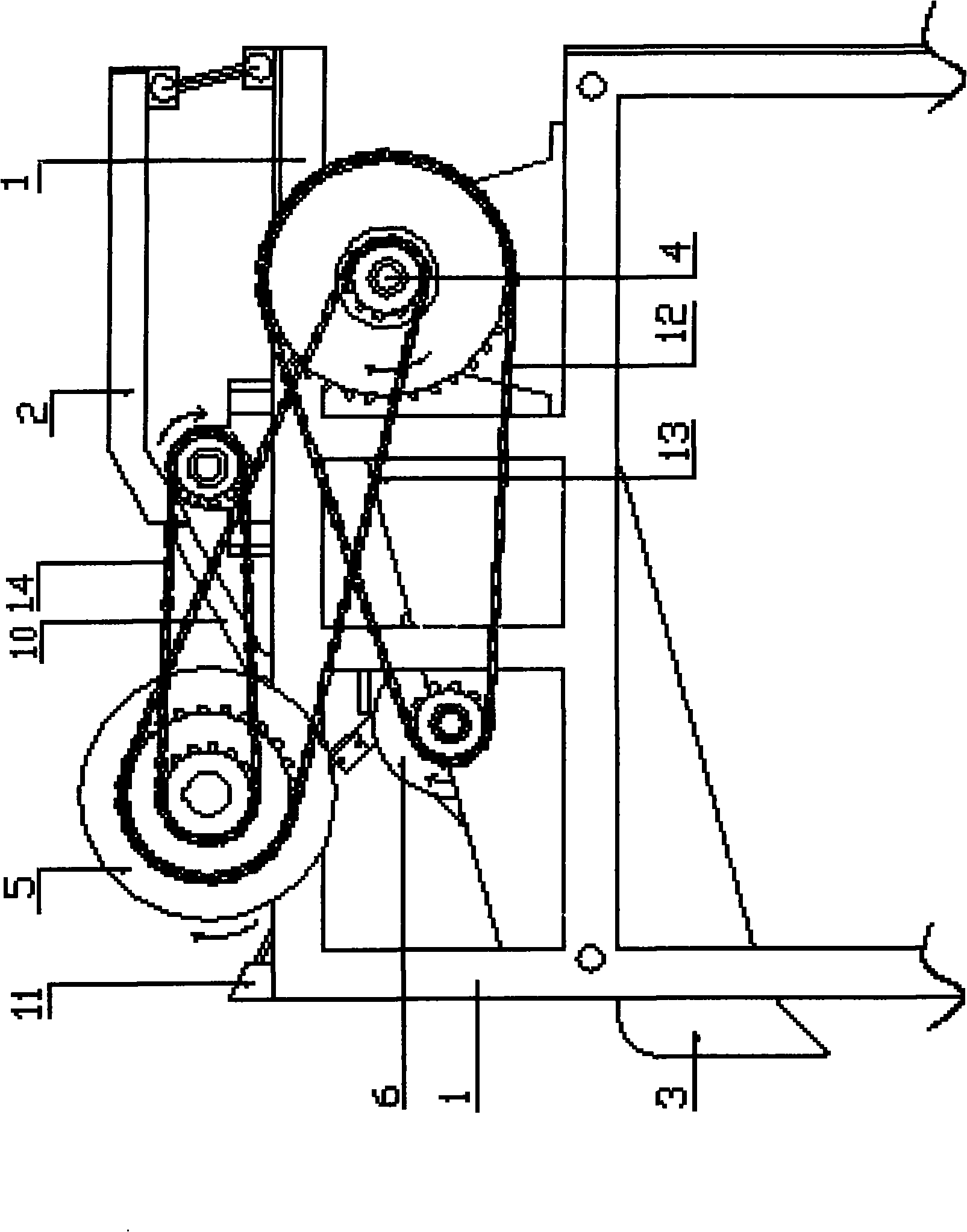

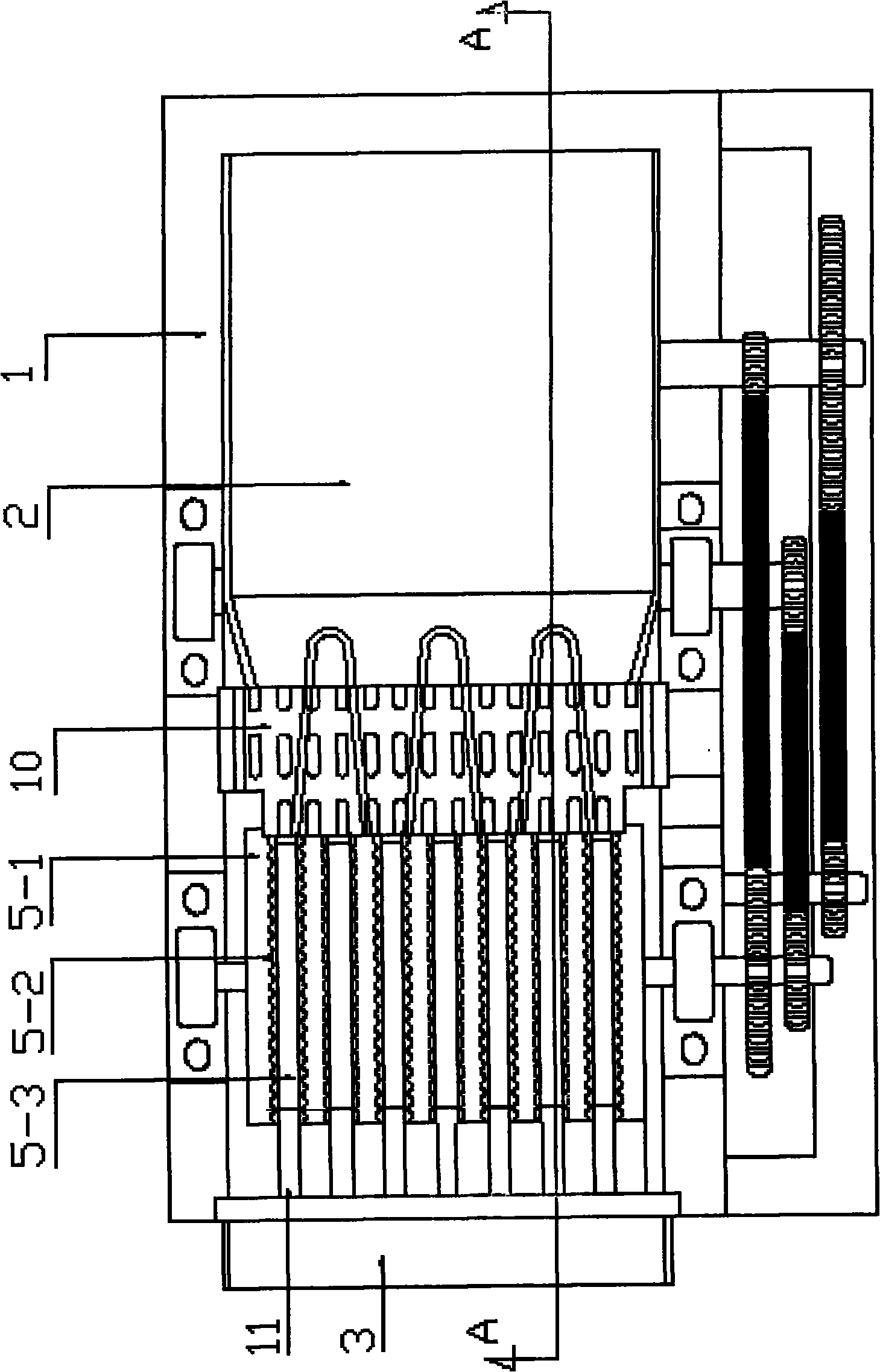

The invention discloses a lichee pericarp girdling machine. The traditional lichee pericarp peeling method is operated manually, and the hazards brought by manual operation are the pollution on lichee flesh and the color and taste change of lichee flesh, thus reducing the quality of lichee products. In the invention, a rotatable feeding roller wheel and a rotatable rebarring wheel are respectively arranged on a rack through bearings, a feeding active bar is arranged below the feeing roller wheel. Lichees enter the rotary feeding roller wheel and the rotary rebarring wheel orderly, a blade girdles a circle of lichee peel, and the lichee peel is divided into two pieces to provide conditions for the following peeling off and denucleating work procedures. The invention completely realizes mechanical and automatic production, and lichee can be peeled off in a short time, thereby ensuring the quality of lichee flesh, reducing the probability of artificial pollution, and realizing industrialized production of lichee fruit juice, lichee pulp, lichee preserved fruit and other lichee products.

Description

Lychee Peel Ring Cutting Machine technical field The invention relates to a lychee pericarp circumcision machine, which can circumscribe the surface of the lychee pericarp for a circle, so that the surface of the lychee pericarp is cut into two petals. technical background The first prerequisite for the industrial production of lychee pulp, lychee juice, lychee preserved fruit and other lychee products is to remove the skin. Traditional lychee peeling methods are all manual operations. The harm caused by manual operation is the pollution of lychee meat, the discoloration and odor of lychee meat, and the reduction of the quality of lychee products. We all know that the shelf life of lychee is extremely short, and it is easy to change color and taste. It often occurs that "the color changes in one day, the fragrance changes in two days, the taste changes in three days, and the color and fragrance disappear in four or five days". This is because there are catechin-condensed ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23N7/00

Inventor 满富桂陈远艺宁进辉叶固权冯勋健

Owner 合浦果香园食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com