Composite material film containing poly N-isopropylacrylamide component and preparation method thereof

A polynitrosopropylacrylamide and composite material film technology, applied in the field of composite material film, can solve the problems of poor mechanical strength of PNIPAAm and the like, and achieve the effects of simple and convenient preparation method, convenient application and poor mechanical performance improvement.

Inactive Publication Date: 2010-08-25

SICHUAN UNIV

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, existing studies have reported that PNIPAAm has poor mechanical strength and cannot even bear its own gravity in the swollen state.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

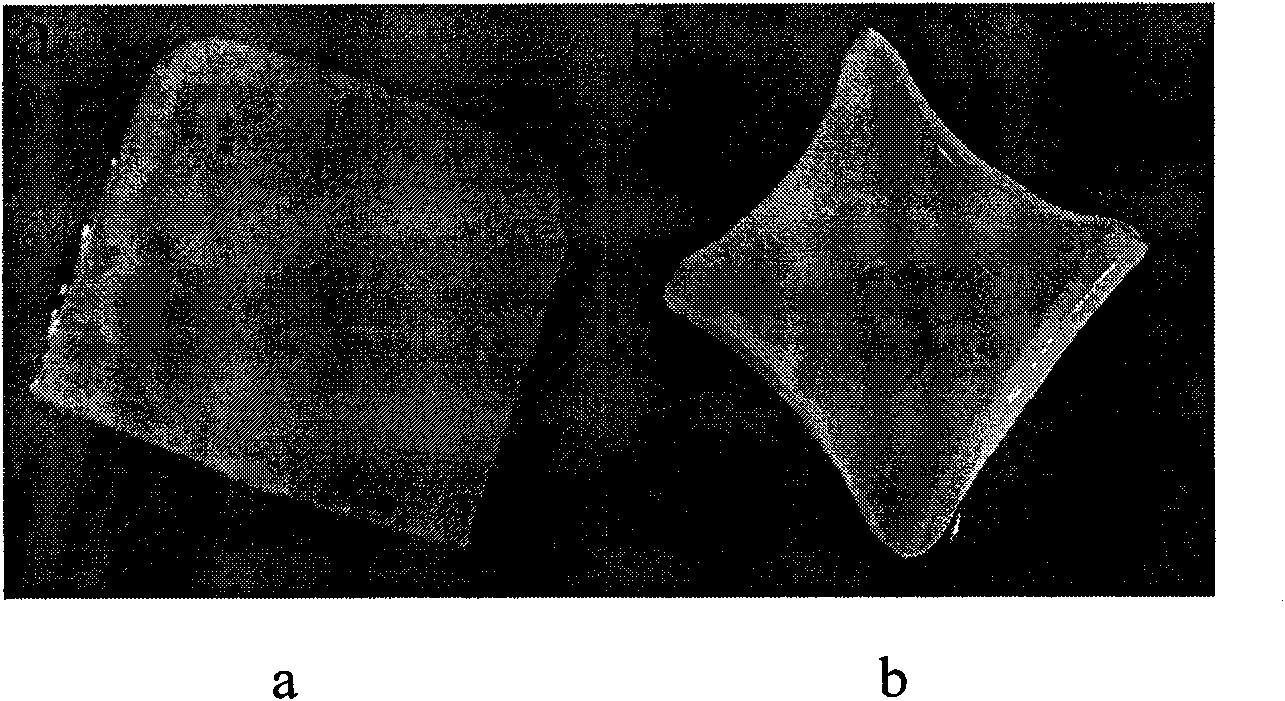

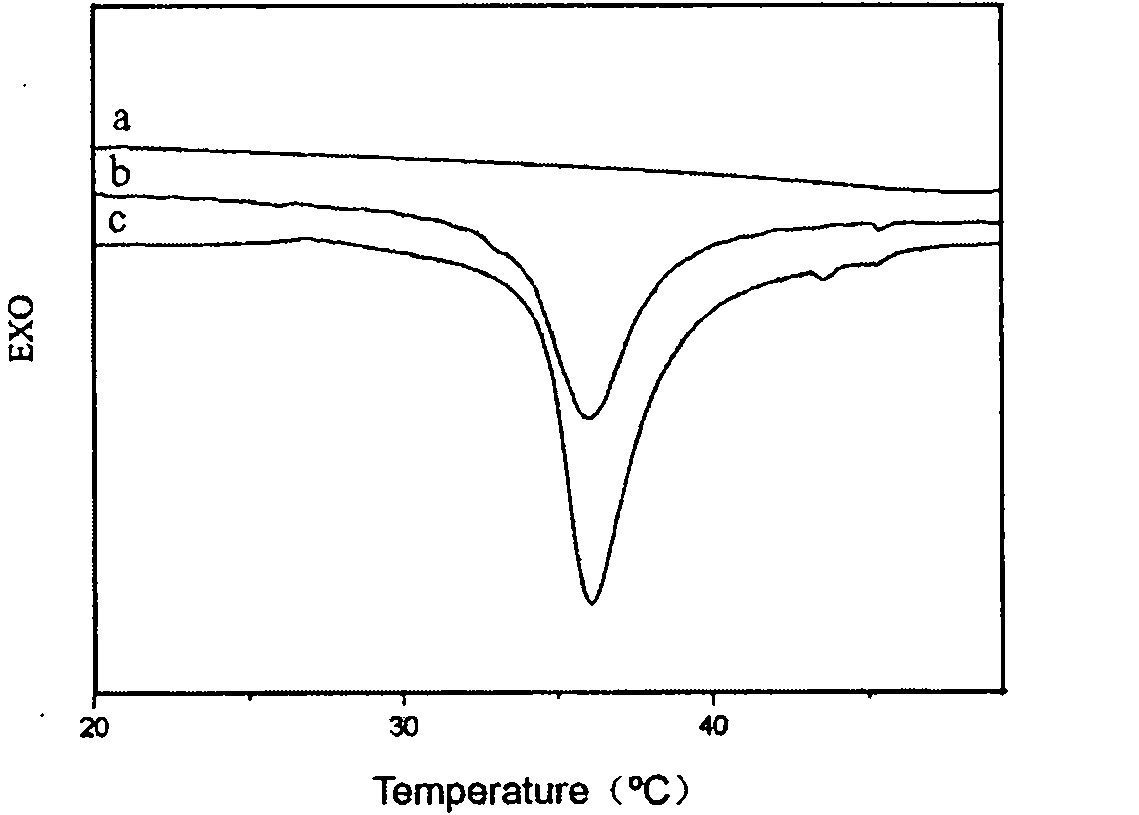

The invention relates to a composite material film containing a poly N-isopropylacrylamide component and a preparation method thereof. A film forming material of the composite film is poly N-isopropylacrylamide and chitosan components, wherein the mass content of the chitosan components is from 10% to 70%, and the balance of the poly N-isopropylacrylamide components. The preparation method comprises the steps of: fully mixing a solution containing the poly N-isopropylacrylamide (PNIPAAm) with the proportion ratio and a cross-linking chitosan solution for reaction under stirring; paving and drying the reactants; neutralizing the reactants by an alkaline solution until the pH of the solution is from 6 to 7; and cleaning by water to remove impurities and obtain the composite material film product. The composite material film has good thermosensitivity and uniform film forming property, improves the property of poor mechanical performance under a swelling state of the PNIPAAm (poly N-isopropylacrylamide), greatly widens the application range, and has more convenient application in the aspects of drug slow release, material separation and purification as well as medical materials. The preparation method is simple and convenient.

Description

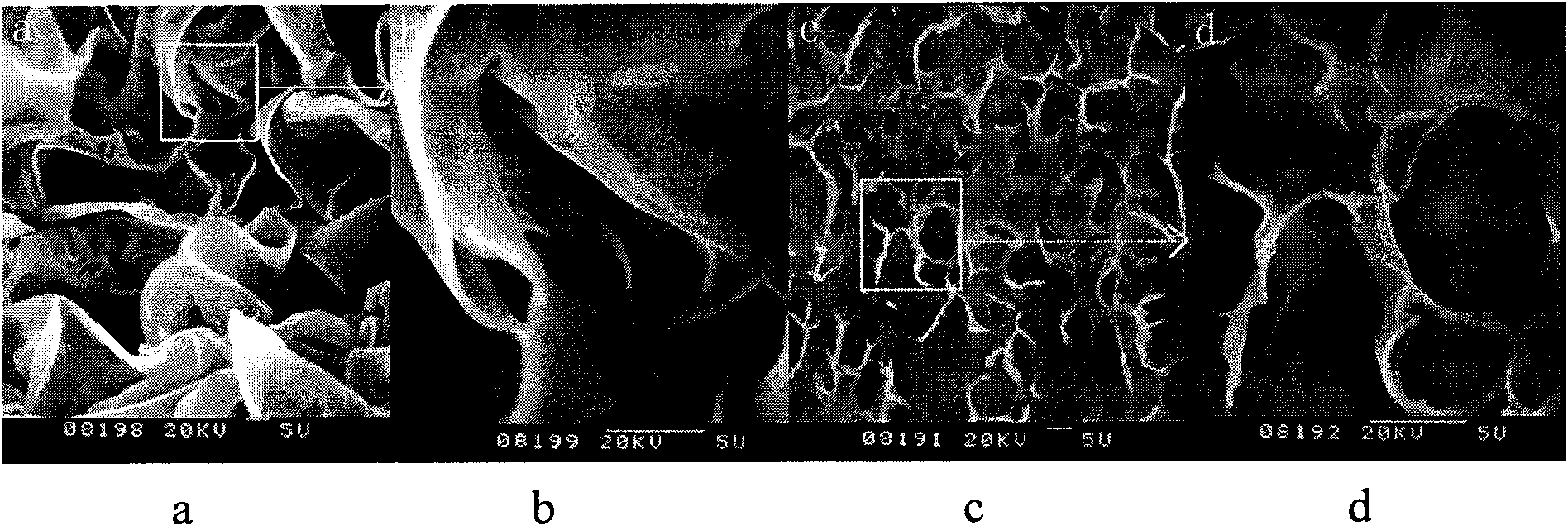

Composite material membrane containing poly(Ni)isopropylacrylamide component and preparation method thereof technical field The invention relates to a composite material film with temperature-sensitive properties, in particular to a temperature-sensitive composite material film containing polyazidopropylacrylamide component, and a related preparation method. Background technique Poly(NIPAAm) belongs to a kind of intelligent material, which has good temperature sensitivity and can shrink or swell dozens of times or even hundreds of times below the critical solution temperature within about 1 °C, so it is obtained He has done extensive research, mainly in the fields of medical materials, biomaterials, chemical mechanical valves and sensing elements. However, existing studies have reported that PNIPAAm has poor mechanical strength and cannot even bear its own gravity in the swollen state. In order to improve the mechanical strength of PNIPAAm, introducing materials with high...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L33/26C08L5/08C08J5/18

Inventor 张利李砚李玉宝

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com