Automatic outage delay device

A power-off device and automatic technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as a large increase in bearing wear, and achieve the effects of prolonging life, reducing wear, and reducing psychological burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

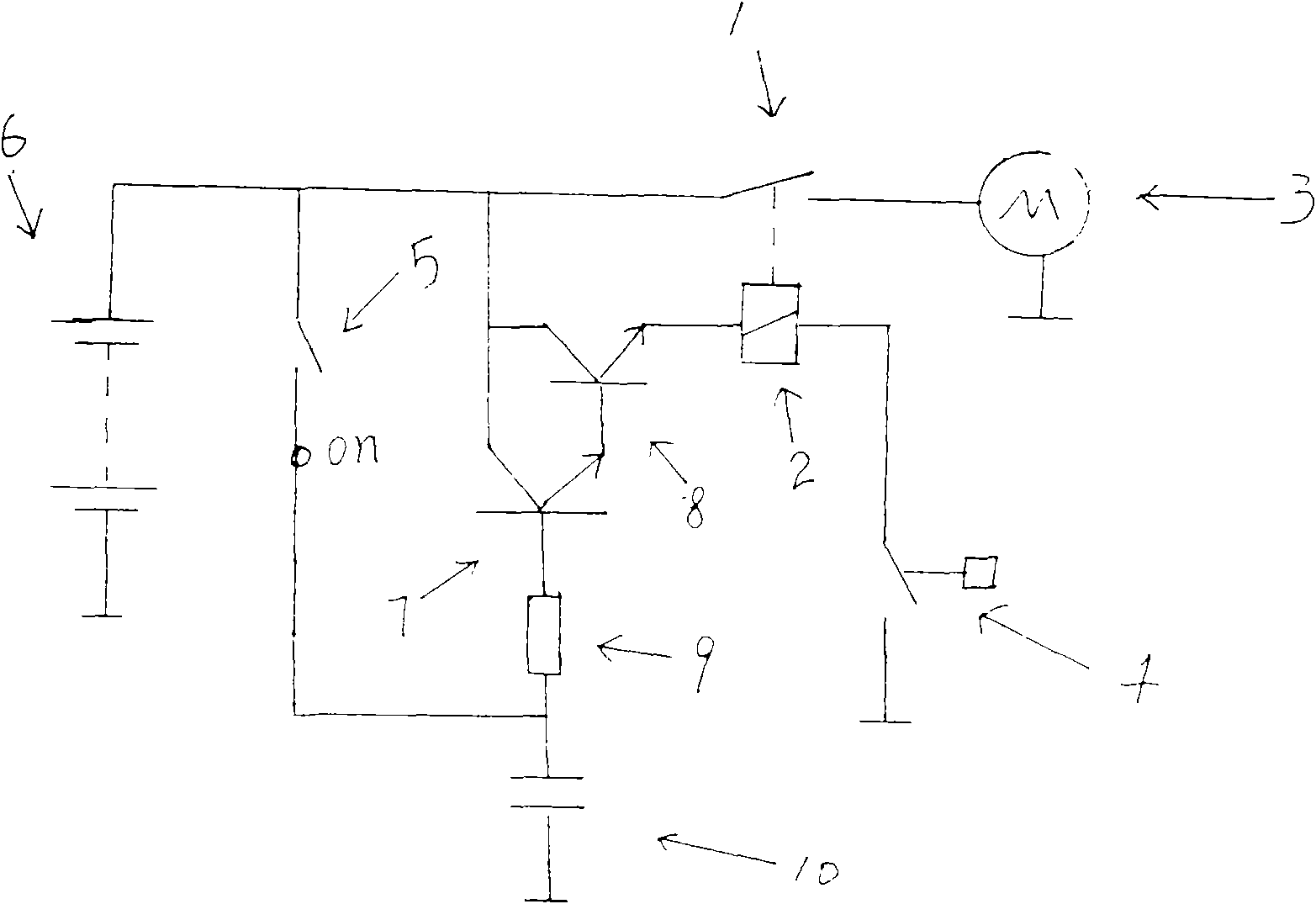

[0024] (1) The power supply circuit of the motor 3 is composed of the normally open contact 1 of the relay and the storage battery 6;

[0025] (2) The accumulator 6, the triode 8, the triode 7, the magnetic coil 2 and the oil pressure switch 4 are connected in series; The emitter, the circuit output end of the magnetic coil 2 is connected to the terminal of the oil pressure switch 4, the emitter of the triode 7 is connected to the base of the triode 8, and the base of the triode 7 is connected to the resistor 9.

[0026] (3) A delay circuit is composed of a resistor 9 and a capacitor 10; one end of the resistor is connected to the base of the triode 7, the other end of the resistor is connected to the on terminal of the key switch 5 and the positive pole of the capacitor 10, and the negative pole of the capacitor 10 is grounded.

[0027] Below in conjunction with accompanying drawing of description and specific embodiment, the present invention will be further described, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com