Soft subdivision method of moire frange signal of grating

A Moiré fringe and grating technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of residual DC level and DC level, high-order harmonics of signals, and inconsistency of two-channel signal amplitudes, so as to improve the accuracy and Resolution, simple hardware effects

Active Publication Date: 2010-08-25

CHONGQING UNIV OF TECH

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the influence of the manufacturing process of the grating sensor, the lighting source, the grating gap, the grating diffraction, the characteristics of the photoelectric element, the power supply and the ambient temperature, the output signal of the photoelectric element contains high-order harmonics, residual DC level and DC level drift. , Inconsistent amplitude of two signals, poor phase orthogonality of two signals, etc. These factors directly affect the accuracy and reliability of various existing subdivision methods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

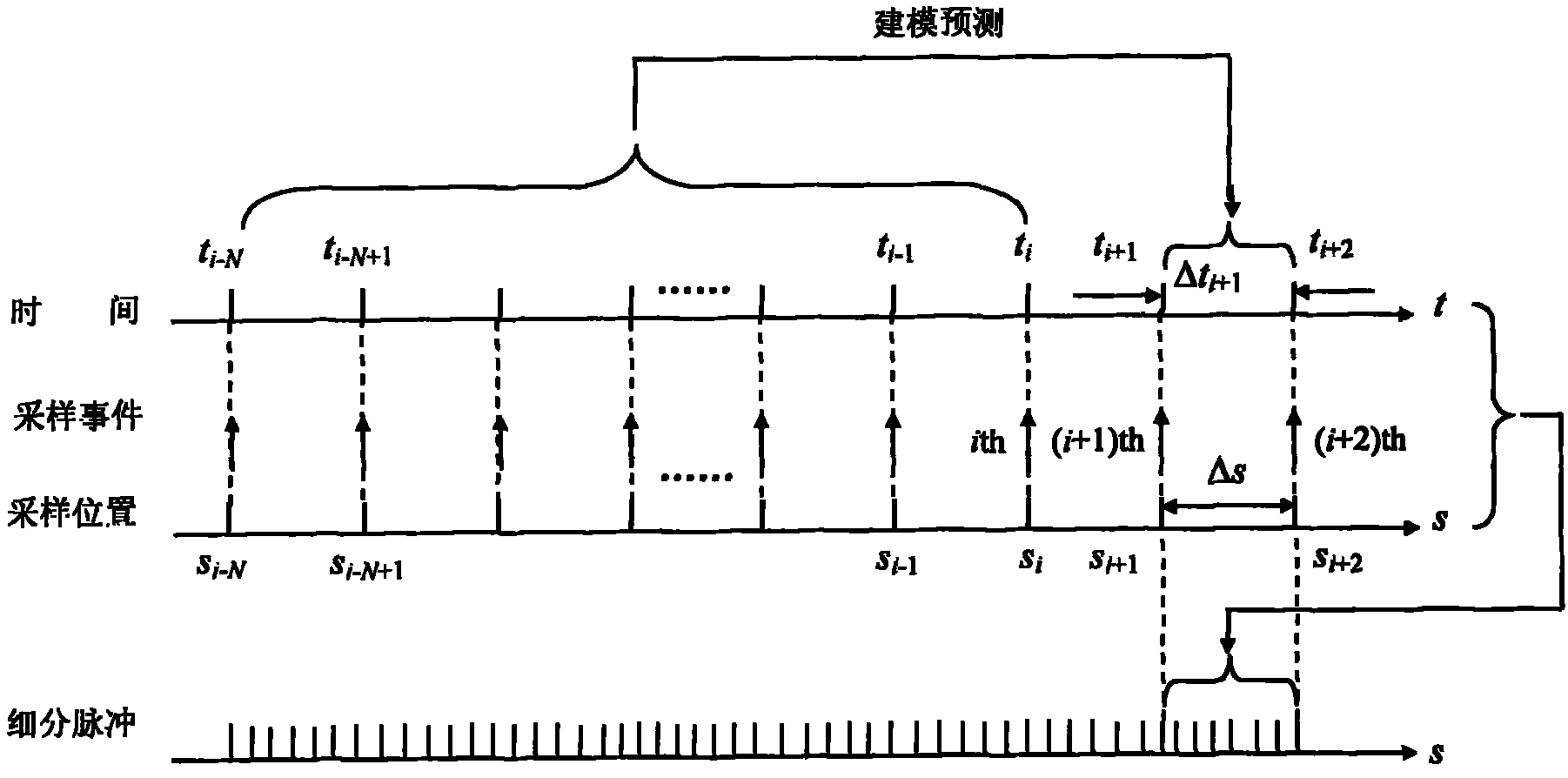

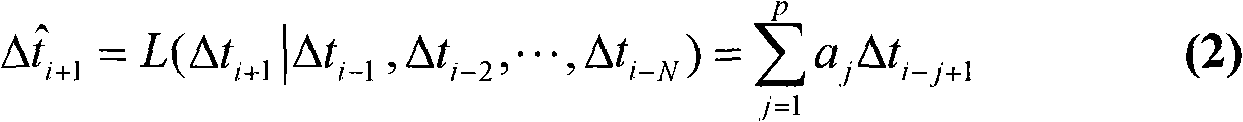

The invention provides a soft subdivision method of a moire frange signal of grating by adopting a micro-processing technology, which generally comprises the following steps of: transforming the information of space domain into time domain to process by using the space-time transformation technology; processing the data via software by using the theoretical modeling technology of time sequence to finish the accurate prediction of time capacity; then returning to the space domain by using the high-speed microprocessor technology and outputting the time pulse with spatial meaning to finish real-time subdivision of the moire frange signal of grating; and finally performing real-time correction on the subdivision error. The invention is applicable to high expansion subdivision of the moire frange signal of grating and improves the precision and resolution of the grating measurement system.

Description

technical field The invention relates to a new signal processing method of a precision displacement measuring sensor (including angular displacement and linear displacement). Background technique At present, grating technology is used in more than 90% of the field of precision displacement measurement. The measurement standard adopts periodic grating lines divided by space, and the displacement is obtained by counting the lines. Precision measurement requires the ability to measure straight lines of 1 μm to 0.1 μm and angles of 1″ to 0.1″. Such accuracy and resolution are difficult to achieve only by the precise engraving of the grating sensor itself. Therefore, it is necessary to subdivide the original Moiré fringe signal of the sensor, and use subdivision methods to improve the accuracy and resolution of the measurement system. The existing subdivision methods mainly include four categories: optical subdivision method, mechanical subdivision method, electronic subdivisio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01B11/25

Inventor 刘小康彭东林杨继森郑方燕

Owner CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com