Gate driving circuit

A gate drive circuit and circuit technology, applied in electrical components, electronic switches, adjusting electrical variables, etc., to achieve the effect of reducing raw materials, efficient thermal design, and suppressing the deviation of conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

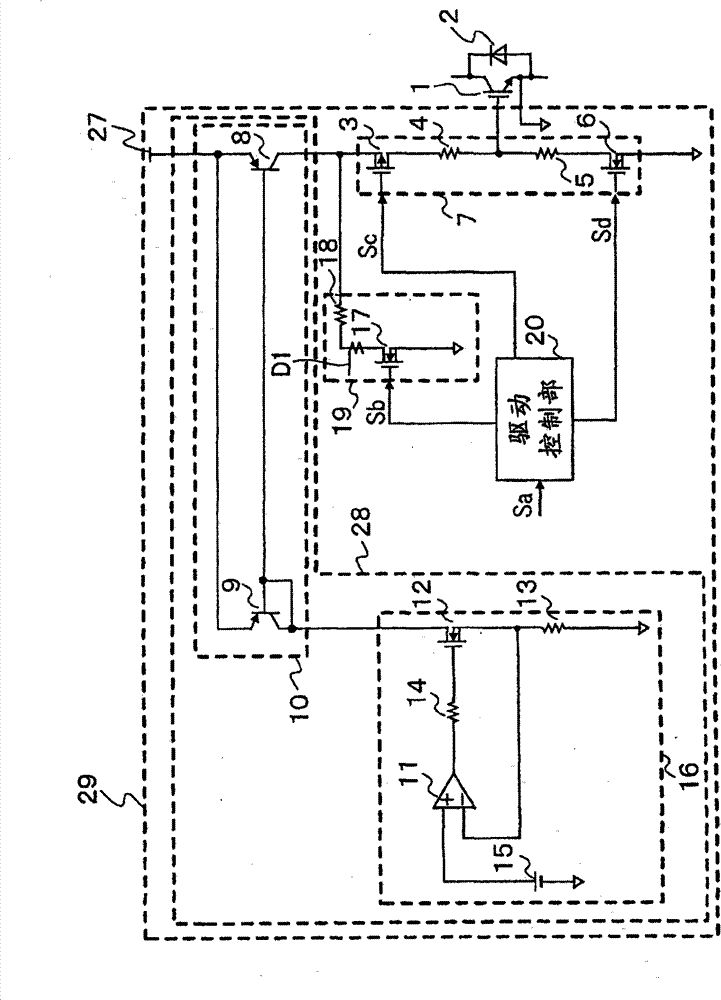

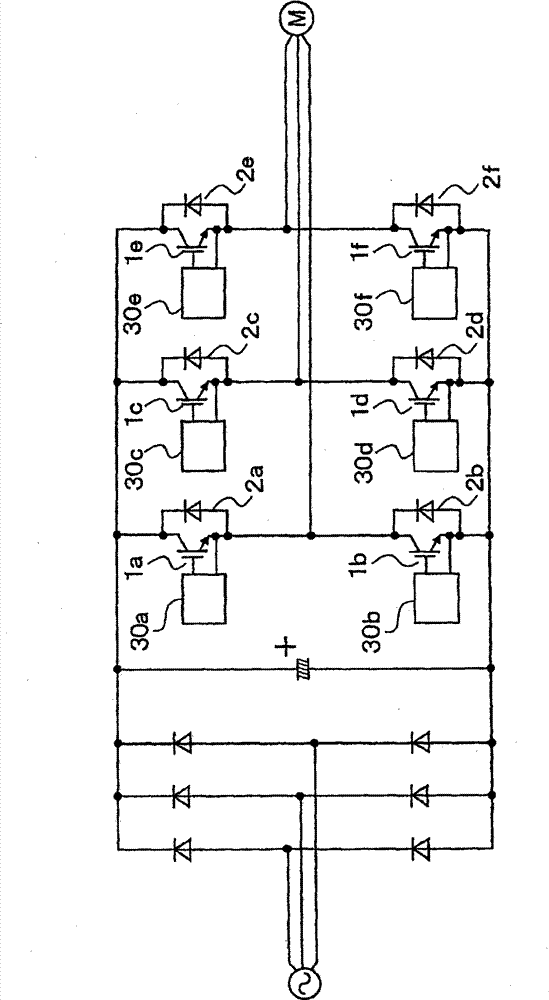

[0030] figure 1 It is a circuit diagram of the gate drive circuit in Embodiment 1 of this invention. As the semiconductor element 1 for power, an IGBT1 (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) is used. However, not limited to IGBTs, even if they are composed of other switches such as FET (Field Effect Transistor) or switches using not only silicon but also other materials such as silicon carbide (SiC) and gallium nitride (GaN), the same The effect is self-evident. The combination of IGBT1, diode 2, and gate drive circuit 29 described here can be used for example figure 2 In various power converters such as the 3-phase inverter circuit shown.

[0031] exist figure 2 Among them, 1a to 1f represent power semiconductor devices (IGBTs), 2a to 2f represent diodes, and 30a to 30f represent gate drive circuits. The gate drive circuits 30a to 30f control the switching of the power semiconductor elements 1a to 1f with respect to the current obtained...

Embodiment approach 2

[0049] Figure 6 It is a circuit diagram showing a gate drive circuit according to Embodiment 2 of the present invention. exist Figure 6 In , the same or related symbols are used to denote the same or equivalent parts as those in the above-mentioned embodiment, and description thereof will be omitted. exist Figure 6 In the gate drive circuit 29a, the preliminary energization circuit 19a is connected to the gate terminal of the IGBT1, and the preliminary energization circuit 19a is composed of an N-channel MOSFET 17a and a resistor 18a as a second switch for controlling the current to the gate terminal of the IGBT1. constitute. The drain of N-channel MOSFET 17a is connected to the gate terminal of IGBT1 via resistor 18a, the gate is connected to drive control unit 20, and the source is connected to the ground side.

[0050] Figure 7 shown for illustration Figure 6 Timing diagram of the operation of the circuit. Figure 7 (a) shows the control command signal Sa, (b) s...

Embodiment approach 3

[0056] Figure 8 It is a circuit diagram of a gate drive circuit according to Embodiment 3 of the present invention. exist Figure 8In , the same or corresponding parts as those in the above-mentioned embodiment are denoted by the same or related symbols, and explanations thereof are omitted. exist Figure 8 In the gate drive circuit 29b, the constant current circuit 16a is usually set to a small current, and is set to a large current only when necessary. Therefore, a resistor 23 is connected in series with the setting resistor 13 for setting the constant current value of the constant current circuit 16a, and a switch 24 for short-circuiting both ends of the resistor 23 is connected in parallel with the resistor 23. Furthermore, comparators 22 and 26 are provided, and the comparators 22 and 26 are connected to the gate terminal of the IGBT 1 and compare the gate voltage with a preset voltage.

[0057] The first reference power source 21 that generates the first reference v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com