Magnesium and magnesium-alloy quantitative casting furnace

A magnesium alloy, quantitative furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of not having the ability to heat quantitative magnesium melt alone, unstable metal quality, increased safety hazards, etc., and achieve social value prospects Visible results, clear quantitative mode, simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

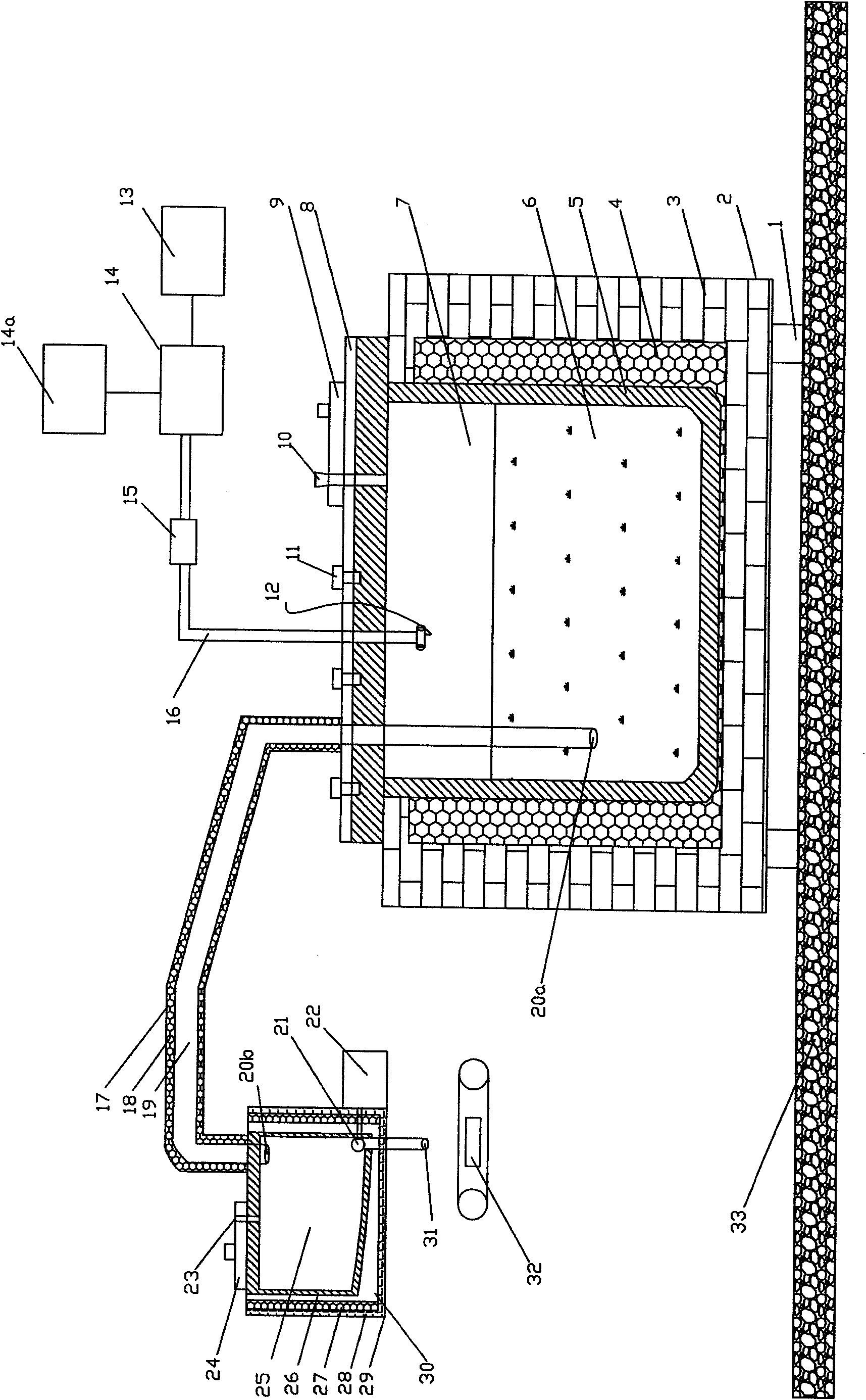

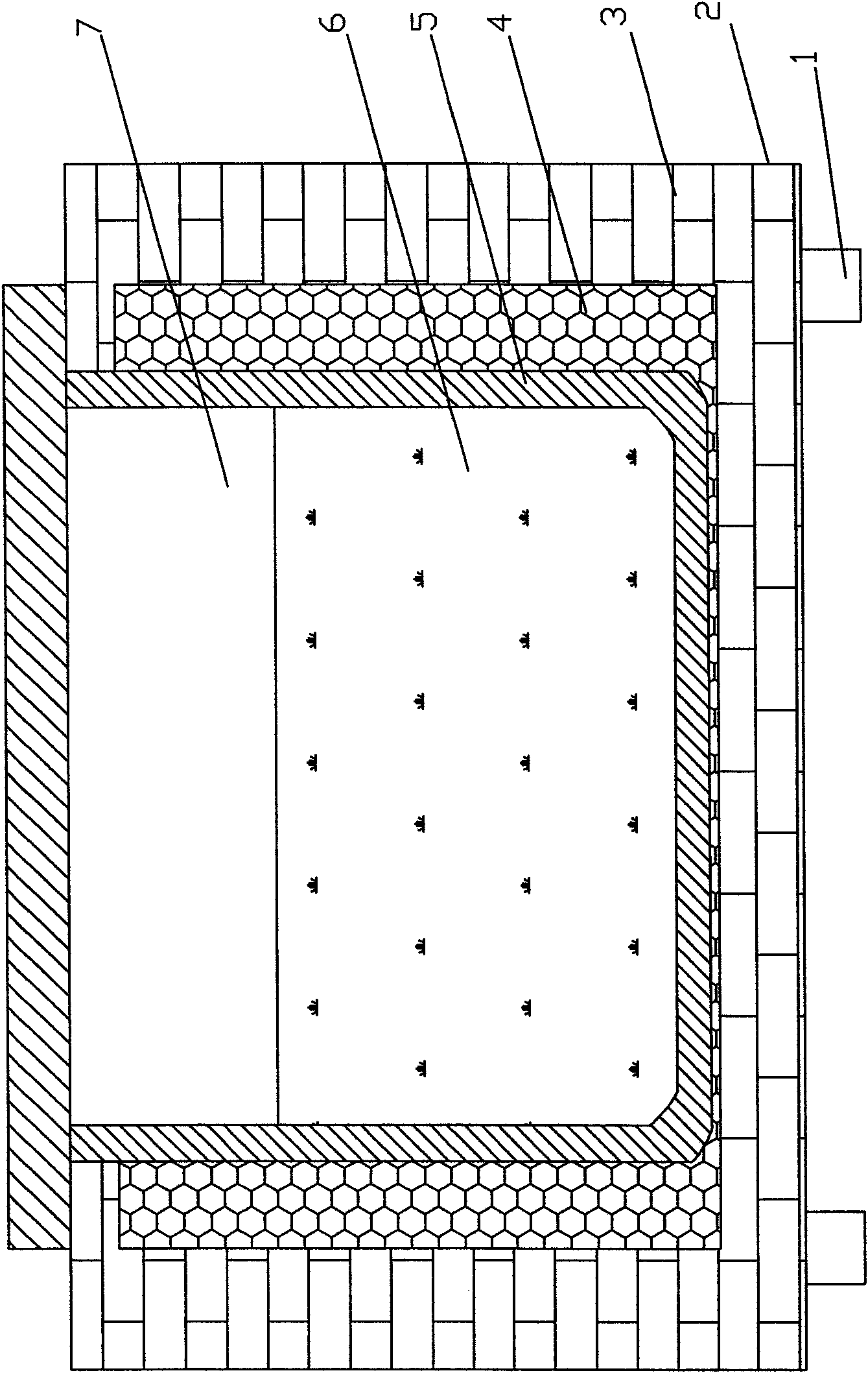

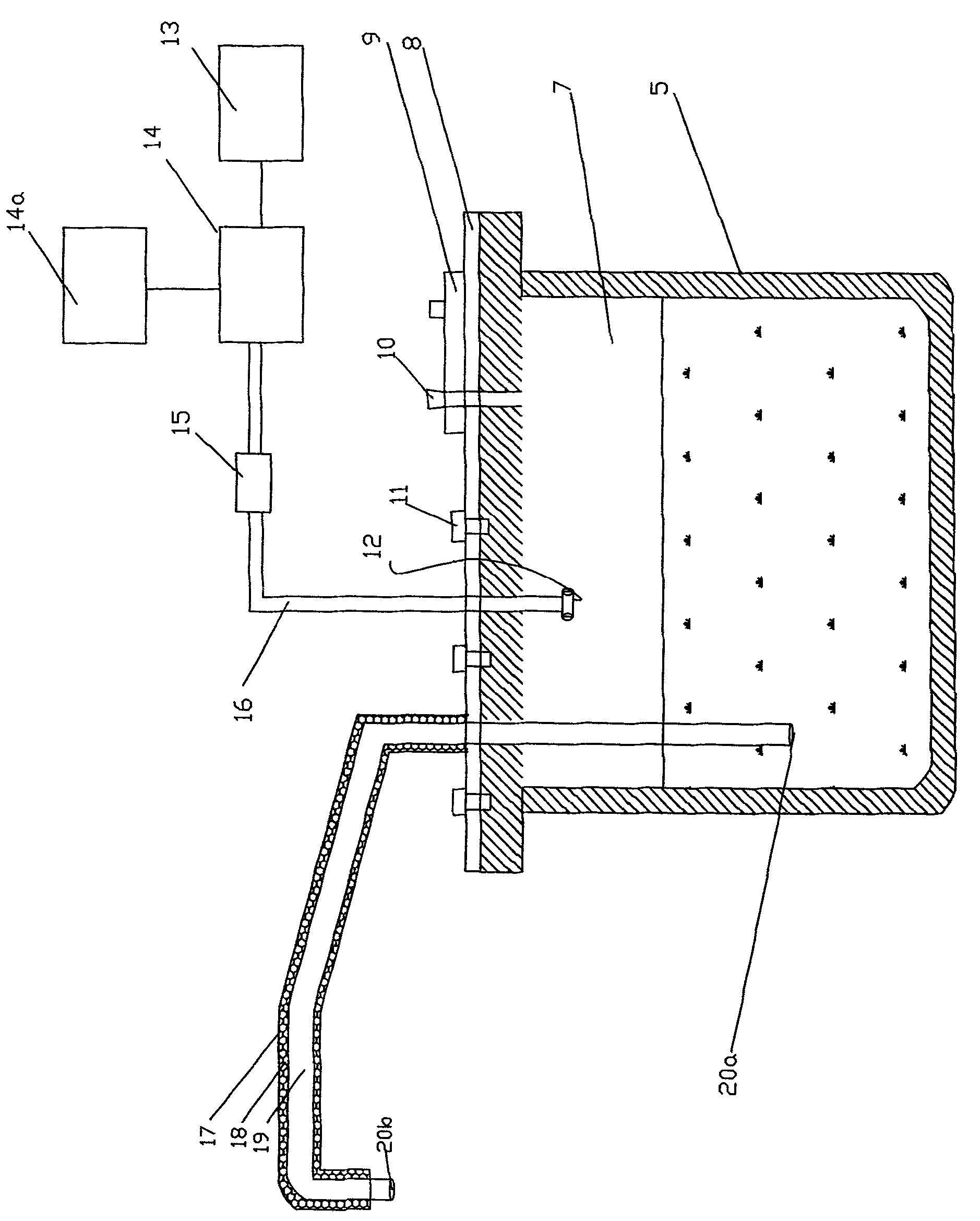

[0026] The present invention will be further described in detail below in conjunction with the specific embodiments of the accompanying drawings.

[0027] Figure 1 to Figure 4 It is a schematic diagram of the structure of the present invention, and the reference numbers are: fixed feet 1, first shell 2, first heat insulation layer 3, first heating element 4, large-capacity crucible 5, first melt chamber 6, pressure chamber 7, metal cover plate 8. Sealed furnace cover 9, pressure relief valve 10, screw rod 11, air inlet 12, air inlet controller 13, air inlet device 14, inert gas source 14a, one-way valve 15, air inlet pipe 16, second insulation layer 17 , the second heating element 18, the discharge pipe 19, the discharge suction port 20a, the discharge nozzle 20b, the valve body 21, the quantitative furnace control valve 22, the protective gas inlet 23, the furnace cover 24, the second melt chamber 25 , Quantitative furnace 26, the third heating element 27, the third insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com