Full automatic blanking machine

A blank cutting machine, fully automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of unsuitable blank cutting equipment, achieve the effects of reducing labor intensity, increasing production speed, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

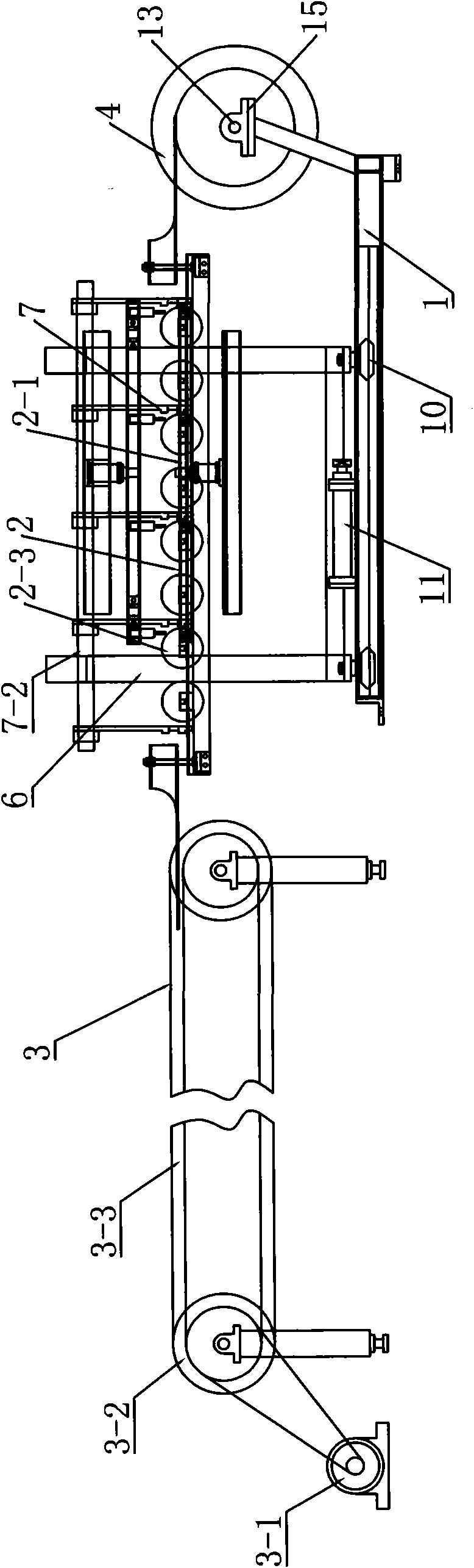

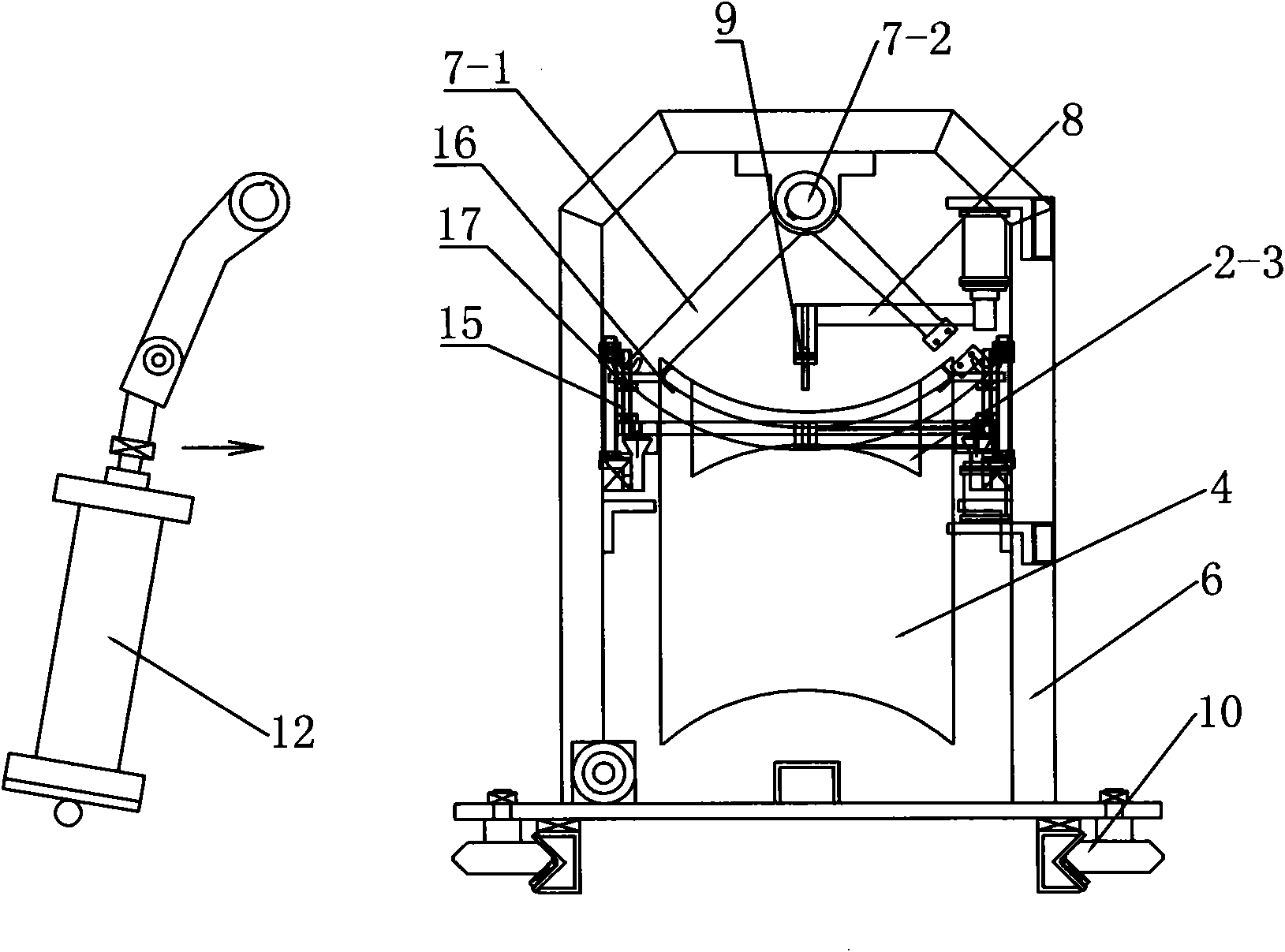

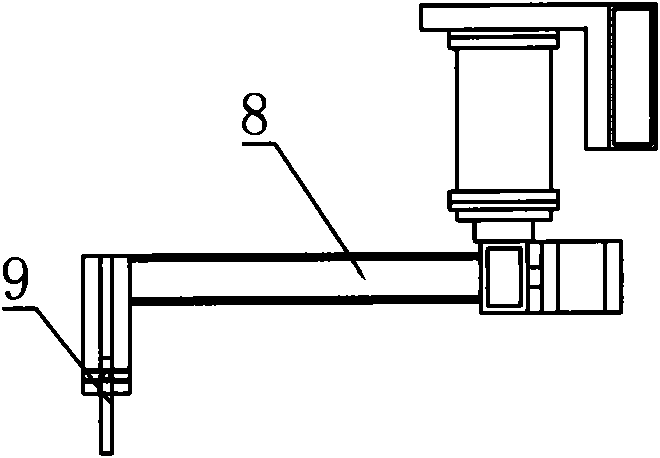

[0032] Such as Figure 1~Figure 13 As shown, a fully automatic billet cutting machine is used in conjunction with the billet discharge machine, including a frame 1, a green body conveying mechanism 2, and the output end of the green body conveying mechanism 2 is provided with a speed regulating motor 3-1, a sprocket 3 -2, and the blank output mechanism 3 formed by the conveyor belt 3-3, which transports the blank to the next station through the conveyor belt 3-3. The front end of the green body conveying mechanism 2 is provided with a travel wheel 4, which is provided with a travel switch 5 corresponding to the green body conveying mechanism 2, and the travel wheel 4 generally adopts light materials such as plastics, wood, aluminum, etc., so that When the green body passes the travel wheel, it can be driven to rotate by friction. The periphery of the body conveying mechanism 2 is provided with a movable support 6 that is consistent with its moving speed and a power device tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com