High negative potential magnesium base alloy sacrificial anode material and application thereof

A sacrificial anode, magnesium-based alloy technology, applied in the field of magnesium alloy materials, can solve the problems of narrow application range, difficult to exceed 55%, open circuit potential and closed circuit potential are not negative enough, etc., to achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

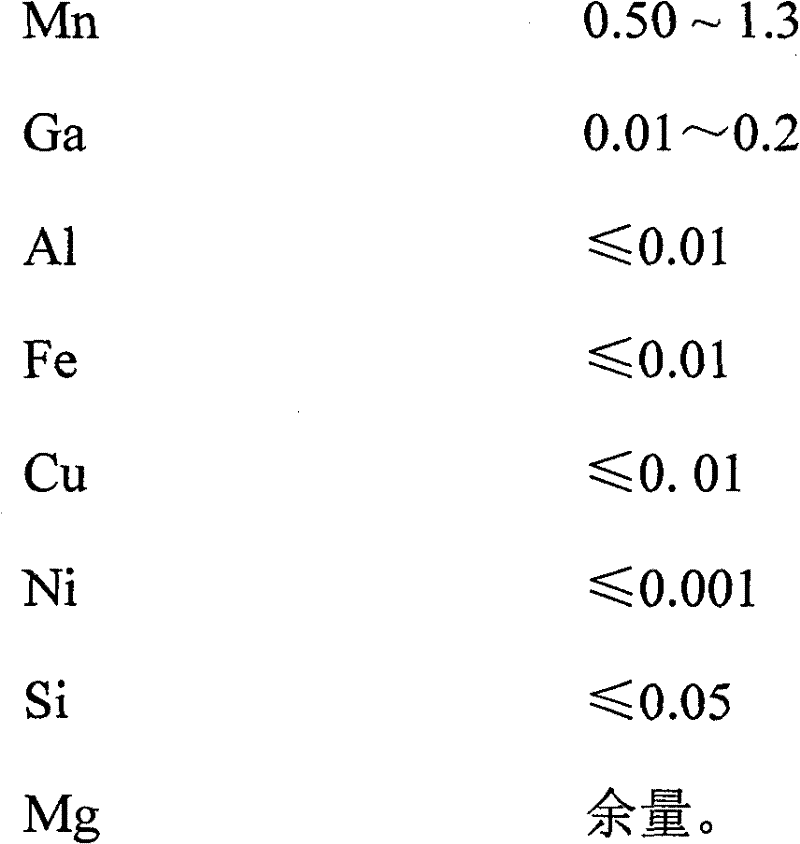

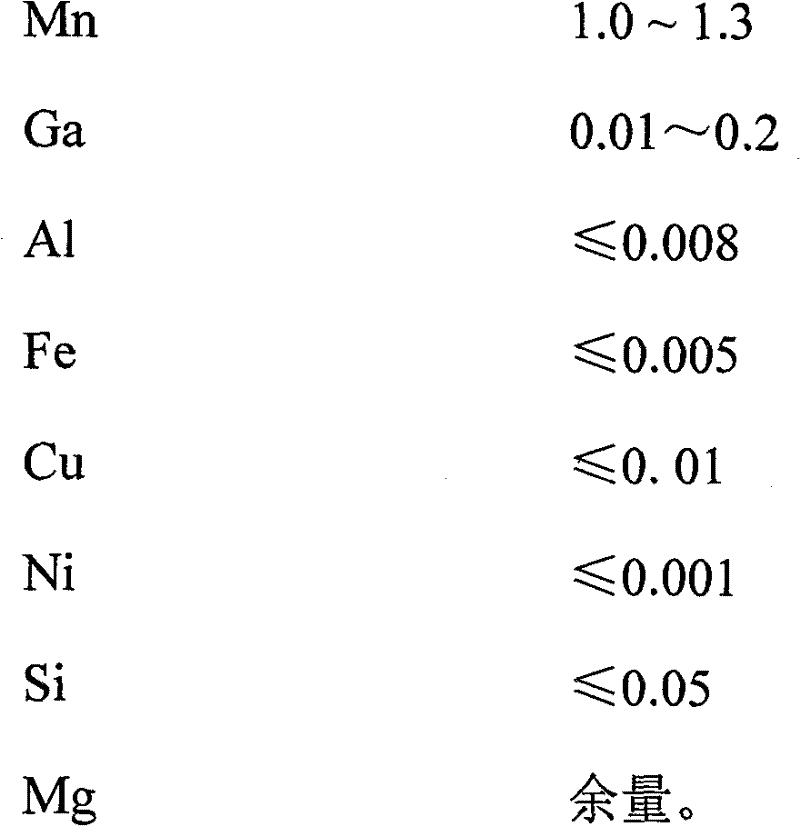

Method used

Image

Examples

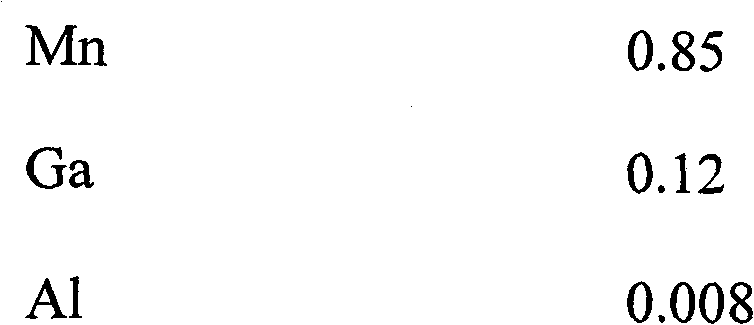

Embodiment 1

[0038] In 100 parts by weight of the high negative potential magnesium-based alloy sacrificial anode material of the present invention, it contains 0.85 parts by weight of Mn, 0.12 parts by weight of Ga, 0.008 parts by weight of Al, Fe≤0.01 parts by weight, Cu≤0.01 parts by weight, and Ni≤0.001 parts by weight parts, Si≤parts by weight, and the balance is magnesium. A high negative potential magnesium-based alloy sacrificial anode manufactured by a rapid water-cooled casting process. Install and use in a water heater at 60-100 degrees Celsius. After testing, the protection effect is very good, there is no potential drop or even reversal phenomenon, and there is no intergranular corrosion and grain shedding phenomenon, the anode corrosion is uniform, the corrosion product is loose, and can fall off automatically. The product sample has been extended to the field of heat exchange equipment.

Embodiment 2

[0040] In 100 parts by weight of the high negative potential magnesium-based alloy sacrificial anode material of the present invention, it contains 1.2 parts by weight of Mn, 0.14 parts by weight of Ga, 0.007 parts by weight of Al, Fe≤0.01 parts by weight, Cu≤0.01 parts by weight, and Ni≤0.001 parts by weight parts, SiO≤0.05 parts by weight, and the balance is magnesium. A high negative potential magnesium-based alloy sacrificial anode manufactured by a rapid water-cooled casting process. It is installed and used in boilers above 100 degrees Celsius. After testing, the protection effect is very good, there is no potential drop or even reversal phenomenon, and there is no intergranular corrosion and grain shedding phenomenon, the anode corrosion is uniform, the corrosion product is loose, and can fall off automatically.

Embodiment 3

[0042] In 100 parts by weight of the high negative potential magnesium-based alloy sacrificial anode material of the present invention, it contains 1.2 parts by weight of Mn, 0.12 parts by weight of Ga, 0.007 parts by weight of Al, Fe≤0.005 parts by weight, Cu≤0.01 parts by weight, and Ni≤0.001 parts by weight parts, SiO≤0.05 parts by weight, and the balance is magnesium. A high negative potential magnesium-based alloy sacrificial anode block manufactured by a rapid water-cooled casting process. In the soil with high resistivity, installing the high negative potential magnesium-based alloy sacrificial anode block to protect the tap water pipeline has a good effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com