Digital automatic oil extraction control system

A control system and automatic technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of judging and adjusting the operating status of oil production equipment in a timely manner, unable to perform balance adjustment, and the working efficiency of oil production equipment needs to be further improved. and other problems to achieve the effect of improving accuracy and improving oil production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

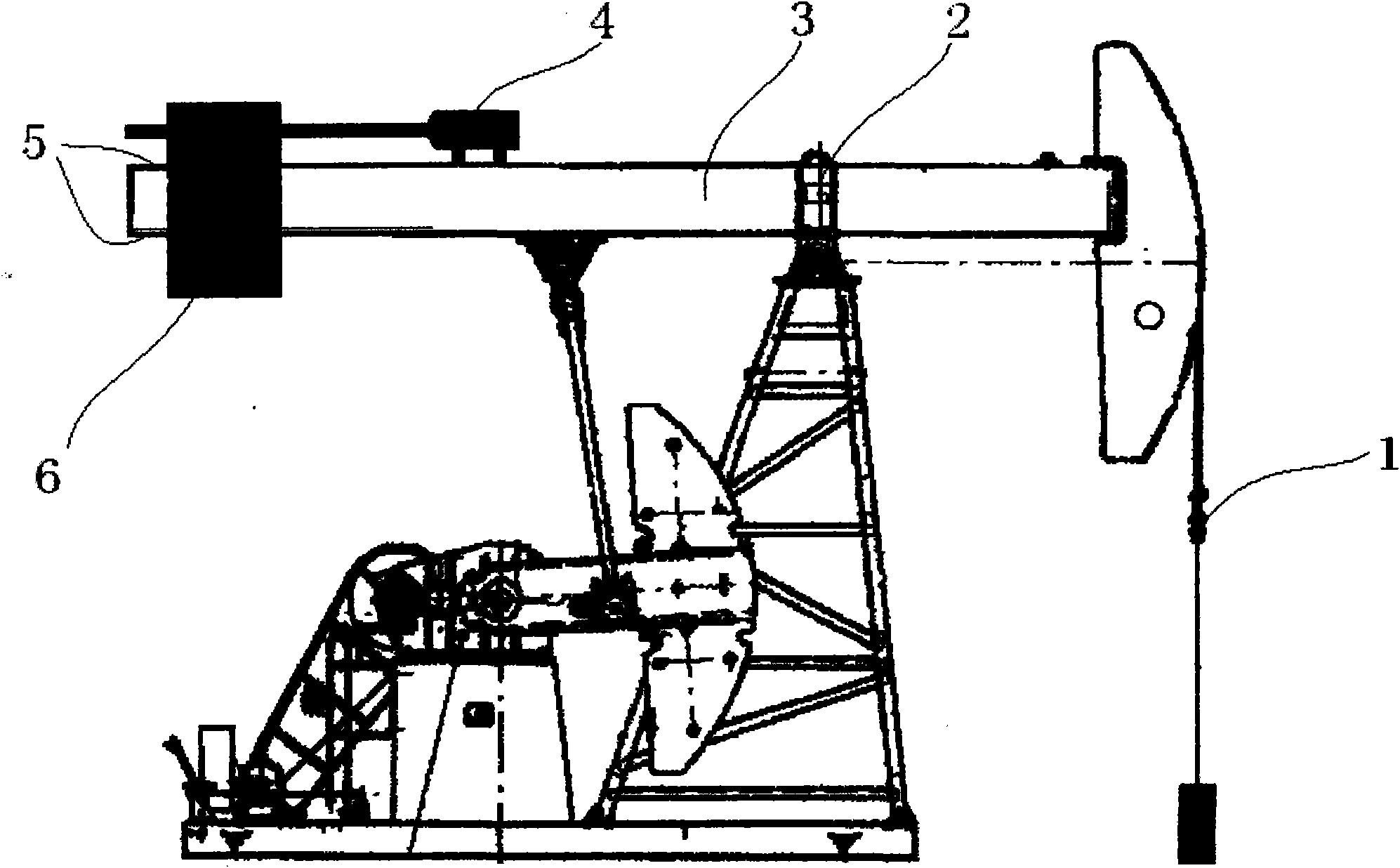

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

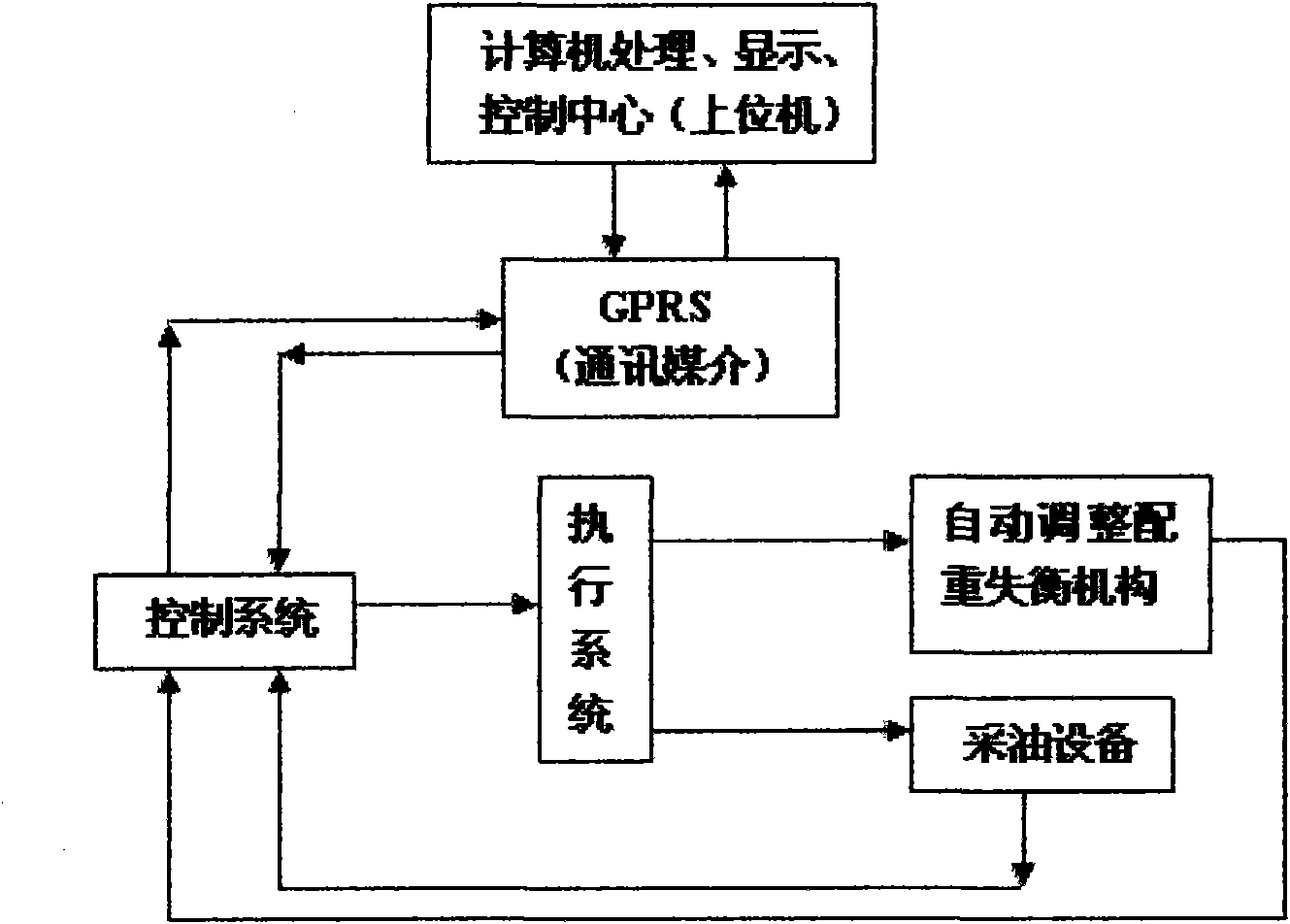

[0018] see figure 1 , the present invention transmits the working information of the oil production equipment to the control system in real time, the control system performs judgment processing according to the set value and transmits the collected raw data information to the control center (host computer) through the communication medium, and the control center can transfer the planned work information And the execution order is transmitted to the control system through the communication medium, and the execution system is notified to execute the order on the automatic adjustment counterweight imbalance mechanism and the oil production equipment.

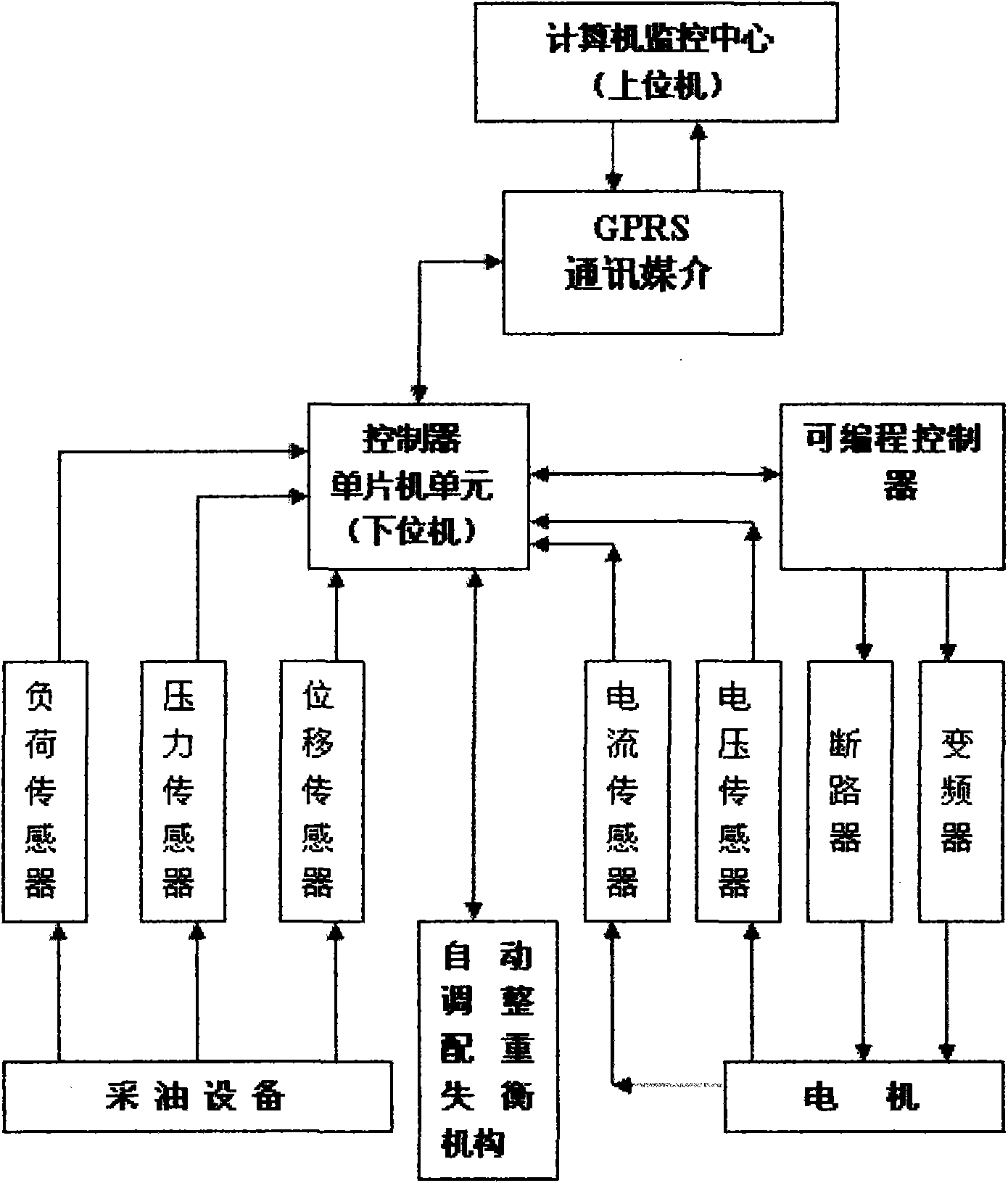

[0019] Specifically, such as figure 2 As shown, the digital automatic oil recovery control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com